Mast Climbers

Mast Climbing Work Platforms: An Industry on the Move

As the markets get busy again, mast climbing work platforms are leading the charge, with evermore inventive solutions for increased productivity, safe work at height, and ergonomic solutions for the management of labor and materials. Owners and rental companies are reporting increased utilization in recent months. The Northeast is showing encouraging growth, with rental companies reporting 60 percent to 70 percent utilization. The Southeast is reporting similar utilization numbers, and mast climbing work platform owners are augmenting their own equipment with rental units again, in significant volume. Similar numbers exist from the Florida Panhandle to Texas.

As the markets get busy again, mast climbing work platforms are leading the charge, with evermore inventive solutions for increased productivity, safe work at height, and ergonomic solutions for the management of labor and materials. Owners and rental companies are reporting increased utilization in recent months. The Northeast is showing encouraging growth, with rental companies reporting 60 percent to 70 percent utilization. The Southeast is reporting similar utilization numbers, and mast climbing work platform owners are augmenting their own equipment with rental units again, in significant volume. Similar numbers exist from the Florida Panhandle to Texas.

California and the Northwest still are relatively quiet for mast climbing work platforms, but this is not necessarily a result of the recession. The West has always been a weaker market for mast climbing work platforms. Many of the more significant projects in the Southeast and Panhandle areas are education and health influenced. Hospital and school construction is significant.

It’s during these times that equipment owners and rental companies need to be mindful of the potential for creating unsafe working conditions as they push to mobilize their workforces and their equipment.

Training and regulations

General contractors are more attuned to training requirements for mast climbers and are demanding proof of formal training as a prerequisite to allowing contractors and rental companies to commence working.

Regulation is playing its part in keeping manufacturers and rental companies on their toes. The OSHA Crane Regulations still have implications on the use of crane arms to lift material onto mast climbing work platform platforms. Additionally, many owners and rental companies are having their installation staff and operators take Level 1 signaling and rigging courses to fully comply.

The SAIA OSHA awareness courses have continued, and this means that compliance officers are now far more aware of issues affecting mast climber safe use. They also are aware of the levels of training required.

Load distribution, stability, safe use, fall protection and inspection are all critical aspects of training.

Comments from OSHA

The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his/her work environment to control or eliminate any hazards or other exposure to illness or injury.

When the above is examined in relation to other OSHA regulations (e.g. the 5a1 clause, which imposes on employers the duty, amongst others, to provide a safe place of work for employees), employers need to be aware of their responsibilities, and carry them out.

OSHA has specific rules for those erecting the equipment:

1926.451(f)(7)

Scaffolds shall be erected, moved, dismantled or altered only under the supervision and direction of a competent person qualified in scaffold erection, moving, dismantling or alteration. Such activities shall be performed by experienced and trained employees selected for such work by the competent person.

Additionally, training and certification can:

- Create productivity and safety advantages

- Reduce unnecessary damage to equipment

- Create a culture of safety and diligence on the jobsite

- Improve communications between the supplier and the customer

- Define more clearly the levels of responsibility in the supply chain

- Reduce maintenance and repair costs

- Provide the right image to regulators and potential customers

- Reduce the chance of misplaced liability, leading to costly and unnecessary defense

- Encourage and retain key personnel.

Inspection and maintenance

As the market gets busier, and mast climber utilization starts to increase, equipment owners find themselves putting equipment back into service that may not have been used for years. It is vital that equipment is properly evaluated, as per manufacturer’s guidelines, for damage, and/or service issues before you deliver it to the jobsite.

Every manufacturer has a detailed inspection regimen, mirrored by the requirements stipulated in ANSI A92.9, the mast climbers American National Standard.

It is vital that your equipment is inspected periodically by someone who is qualified to inspect it. Any identified damage must be repaired according to manufacturer’s instructions, and the inspections and necessary repairs must be properly documented.

Get expert help

Mast climber owners and rental companies need to build strong relationships with both the manufacturer of their equipment, and with the organization(s) that represent the industry. There is a huge information, advice and training resource available from these sources. Take advantage of it.

Hydro Mobile, for example, holds many training courses throughout the year for owners and rental company employees. It’s a fantastic way to improve your knowledge, create qualified personnel, and maintain a close working relationship between not only manufacturer and equipment owner, but also between equipment owners whom you are with for the training. Everyone will have different experiences with mast climbers, will have solved problems in a different way, and will have valuable knowledge to share.

Get onto the manufacturers database for equipment news and updates. The more information you have the better, and the manufacturer can help you with standard reporting formats for inspections and repairs.

As a mast climber owner, don’t go it alone. If an accident happens on a jobsite, that’s exactly what you will be – alone. So, build relationships, get help and advice, train your personnel, and get involved in the mast climber industry.

| News from Premier |

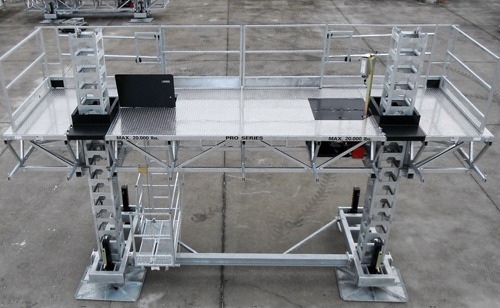

Premier Scaffold Solutions announced it has made the ProSeries mast climber even better. The most recent update includes aluminum diamond plate top sheets. Now, with the new top sheets and with frames being hot-dipped galvanized inside and out, the mast climbing unit is a solid and lasting investment, says Premier. Premier takes pride in its “Built in America” manufacturing plant and continues to listen to customers to make improvements as well as invest in research and development. Currently, the company is working on a single-tower mast climber and partnering up on a?? transport platform that is already out in the field for additional testing. The company says it just finished up a project with Weigand Construction out of Fort Wayne, Ind., at the IU Jacobs Hall location. The customer purchased multiple ProSeries set ups as well as rented additional units from Premier’s sister company, TNT Equipment Co., Columbus, Ohio. The job was not only a typically tight college campus job, but also it had many difficult configurations, with everything from block and brick work to heavy stone pieces. The ProSeries handled with all of this via its modular bridging and heavy capacities. For additional information about Premier Scaffold Solutions, visit www.premierscaffoldsolutions.com, or call Michael Solomon, National Sales Manager for PSS/TNT Cos., 614-560-3898. |