December 2014

Anchors, Connectors, and Fasteners

Anchors and Energy Efficiency

As energy codes continue to reach for higher standards and the cost of energy continues to rise, much attention now is being paid to the various components in our walls that may contribute to or diminish the overall energy performance of a masonry wall system.

Notably, emerging codes are requiring the calculation of thermal transmittance through items like brick ties, Z-girts we see used to support various types of cladding panels, and relieving angles.

Are you thinking that the role played by something as small as a masonry anchor in the thermal performance of a wall system is insignificant? Think again. Studies suggest that the masonry ties can contribute to as much as a 30 percent to 40 percent reduction to the R-Value of the wall’s continuous insulation system. The cause of this energy loss? Thermal bridging through the insulation barrier and air infiltration through the building envelope.

|

|

Thermal bridging is most simply described as the transfer of thermal energy (heat) channeled through or bypassing the thermal barrier via highly conductive materials, as we find in fasteners, anchorage, slab edges, etc. We have concerned ourselves for years with the development of condensation in steel stud walls caused by thermal bridges as the flanges of the studs themselves would provide a means by which heat could bypass the insulation tucked into the stud bays. It is with today’s better technology in energy modeling that we also consider the potential of energy loss through thermal bridges.

In order to understand the potential for concern, one must first understand how thermal energy is transferred. Thermal energy (heat) moves from higher temperatures to lower temperatures, the speed of which is based on conductivity of the material to which it is being transferred.

This is best illustrated by the following example: If you were to step barefooted onto a cold porcelain floor, heat is transferred from your foot to the tile, as opposed to cold being transferred from the tile to your foot. Because porcelain is a good conductor of thermal energy, your feet will tend to feel cold quickly. Now picture the same scenario, but instead of stepping onto a tile floor you step onto a hardwood floor. The thermal energy transfer will still take place, but perceived at a slower rate, because wood is much less thermally conductive.

|

|

So let’s apply this basic concept to a steel stud wall commonly constructed today consisting of 1/2-inch interior gypsum, six-inch studs, 5/8-inch sheathing, an air/vapor barrier, two inches or greater of insulation, a two-inch ventilated air cavity and a masonry veneer. In a climate where the interior temperatures are greater than the exterior, heat from the room will eventually transfer through the interior drywall and to the highly conductive flanges of the stud, routing to the fastener of the brick tie, to the tie itself, and eventually exiting the brick at the exterior, resulting in a reduction of thermal performance of the wall assembly.

This specific type of thermal bridge is mentioned specifically in ASHRAE 90.1 section 3.2 Insulation:

Continuous insulation (c.i.): insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior or exterior or is integral to any opaque surface of the building envelope.

This segment of the code acknowledges the ties create a thermal bridge, but does not require any reduction in R-value calculations for masonry ties or fasteners that protrude through the thermal barrier.

A report by Morrison Hershfield: Thermal Performance of Building Envelope Details for Mid- and High-Rise Buildings addresses these penetrations as well:

- 5.2 Thermal Transmittance – Clear Field Anomalies – Thermal bridges uniformly distributed by a sufficient amount such that they can be assumed to modify the thermal transmittance of the assembly and are considered not practical to account for on an individual basis for whole building calculations. Examples are brick ties, girts supporting cladding, and structural framing.

Conversely, the 2012 Energy Code in the state of Washington defines continuous insulation by modifying the ASHRAE 90.1 language to specifically address the tie portion of the wall:

- Section C202 General Definitions – Continuous Insulation (ci): Insulation that is continuous across all structural members without thermal bridges other than service openings and penetrations by metal fasteners with a cross-sectional area, as measured in the plane of the surface, of less than 0.04 percent of the opaque surface area of the assembly.

In this code, the area of the cross-section of the wall tie must be calculated with the spacing of the ties to assure the ratio is between 0.04 percent and 0.08 percent of the wall surface area. The code also requires that no continuous metal elements (Z-channels, metal studs, shelf angles) penetrate the continuous portion of the insulation, and every penetrating element is individually accounted for on the drawings detailing its dimensions and location. This information is then utilized in various 2D and 3D versions of energy modeling software.

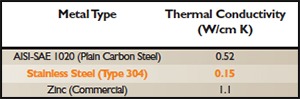

Strategies to minimize thermal bridging and improve energy efficiency should incorporate anchors and ties that are coated with a non-conductive material to reduce the amount of thermal transfer through the insulation barrier, and using more stainless steel as opposed to zinc, as zinc has seven times the thermal conductivity of type 304 stainless steel.

|

|

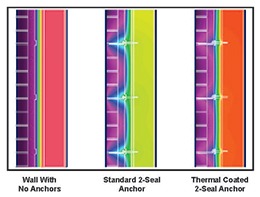

Thermally coated anchors are also showing much improved thermal performance of the wall assembly in 2D and 3D energy modeling. These models show when using a thermally protected anchor the interior wall surface temperatures average 5.9 degrees F warmer than a standard zinc masonry tie when simulating a 69.8 degree F interior temperature and a -0.4 F degree exterior. This is significant, as this relates directly to the building’s heating costs.

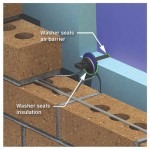

Thermal bridging is not the only concern. Air infiltration through the air/vapor barrier is of enormous concern. This is very true in steel stud construction, because you are guaranteed to penetrate the barrier as it is usually installed before the ties are fastened to the backup wall. Here, the belt and suspenders approach to maintaining integrity of the AVB should include minimal penetrations at tie locations –ÂÂÂ i.e. installing single screw barrel fasteners and integrated gaskets that seal around the air barrier penetration. An integrated gasket requires no secondary detail tape to act as a sealing mechanism, and no extra effort for the installer.

Am I suggesting that the anchors and ties have been the largest cause for concern in our wall performance? Certainly not. Larger elements such as relieving angles are surely transferring more thermal energy than a brick tie. Air barrier installations in all building types should be more heavily scrutinized for continuity and performance. Continuous slab edges at balconies continue to act as cooling fins of a radiator, casting tremendous amounts of thermal energy to the outside. And fenestrations and their adjacencies continue to create both air leakage and thermal bridging issues. But, just as items like relieving angles make way for offset knife edge angles to better their thermal performance, we should be working toward bettering all of these conditions as well. If something as simple as a brick anchor can help to better the thermal barrier of a wall and improve its overall performance, we should consider that an easy consideration to make.

Jeremy Douglas, CSI, CCPR, is the director of architectural services for Hohmann & Barnard and has more than 15 years of experience in the masonry industry in addition to working with other various wall systems. He has written dozens of seminars delivered across the country on the subjects of moisture control, building envelope integrity, wall reinforcing and anchoring, and masonry restoration.

|

|

Cintec North America has released Seistec, a CINTEC Reinforcing Anchor System used for seismic repair or for retrofitting seismic upgrading of structures made of brick, stone, terracotta, adobe or timber. Seistec internally strengthens the integrity of wall-to-wall, wall-to-roof and wall-to-floor constructions, while remaining sensitive to the original architecture.CINTEC’s Seistec (SEISmic TEChnology) process begins with an inspection of the structure following a site visit by the engineer of record. The structure is then computer modeled and animated using the discrete element technique to visualize potential stresses incurred during seismic loading. This software analysis assesses the behavioral probability and the risk inherent to the structure in order to determine the best positioning of the CINTEC Reinforcing Anchor System.At the site, the CINTEC Reinforcing Anchor System, fashioned out of a steel bar enclosed in a mesh fabric sleeve, is inserted into the structure in need of reinforcement. A non-polymer, cement-like grout is then injected into the sleeve under low pressure. The grout then fuses with the mesh, expands and shapes itself around the steel to fit the space. CINTEC uses dry- or low-volume wet diamond drilling techniques to reduce or even eliminate water damage associated with conventional wet drilling.The Seistec system may be used in a wide range of masonry materials. The anchor body size and material type can be adjusted, as can the size of the diameter of the cored hole, based on the condition of parent material and requirements of the engineer of record.For more information, visit www.cintec.com. Cintec North America has released Seistec, a CINTEC Reinforcing Anchor System used for seismic repair or for retrofitting seismic upgrading of structures made of brick, stone, terracotta, adobe or timber. Seistec internally strengthens the integrity of wall-to-wall, wall-to-roof and wall-to-floor constructions, while remaining sensitive to the original architecture.CINTEC’s Seistec (SEISmic TEChnology) process begins with an inspection of the structure following a site visit by the engineer of record. The structure is then computer modeled and animated using the discrete element technique to visualize potential stresses incurred during seismic loading. This software analysis assesses the behavioral probability and the risk inherent to the structure in order to determine the best positioning of the CINTEC Reinforcing Anchor System.At the site, the CINTEC Reinforcing Anchor System, fashioned out of a steel bar enclosed in a mesh fabric sleeve, is inserted into the structure in need of reinforcement. A non-polymer, cement-like grout is then injected into the sleeve under low pressure. The grout then fuses with the mesh, expands and shapes itself around the steel to fit the space. CINTEC uses dry- or low-volume wet diamond drilling techniques to reduce or even eliminate water damage associated with conventional wet drilling.The Seistec system may be used in a wide range of masonry materials. The anchor body size and material type can be adjusted, as can the size of the diameter of the cored hole, based on the condition of parent material and requirements of the engineer of record.For more information, visit www.cintec.com. |