January 2015

Technology

Humanoids, Bio Bricks and BIM

In early-2012, following the success of its driverless vehicle initiative, the Defense and Advanced Research Projects Agency (DARPA) issued a call to engineers around the world to develop bipedal robots capable of performing a wide variety of tasks in real-world environments. The main goal of the challenge was to spur the creation of machines that could be employed on disaster sites, like the now defunct nuclear reactor in Fukishima, Japan.

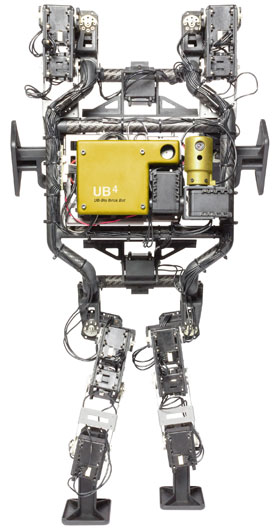

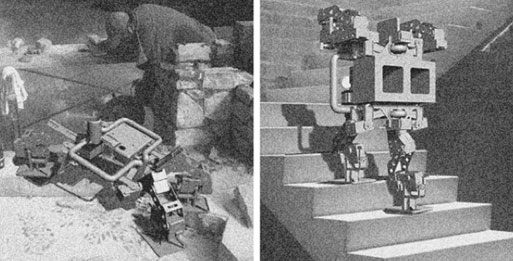

Inspired by the DARPA competition, our team is focusing on the development of situationally aware, “Humanoids” capable of assembling complex structures using green materials. Rather than pursuing new applications for factory-based articulated arms, our project looked at how low-cost, networked devices fitted with sophisticated machine vision technologies could be used to assist workers in the field.

Inspired by the DARPA competition, our team is focusing on the development of situationally aware, “Humanoids” capable of assembling complex structures using green materials. Rather than pursuing new applications for factory-based articulated arms, our project looked at how low-cost, networked devices fitted with sophisticated machine vision technologies could be used to assist workers in the field.

While the demand for highly skilled masons in the United States has never been more robust, a sharp decline in the number of young people learning the trade has led to serious labor shortages. Our robot prototypes are proposed to fill the void. They will be easy to operate, highly maneuverable, leg-based helpers that can sort, carry and stack eco-friendly “Bio Bricks” manufactured using harmless bacteria. Ginger Dosier’s Bio Bricks use bacteria to solidify sand into durable masonry units. The water and energy consumed in the process are significantly lower than conventional block manufacturing techniques.

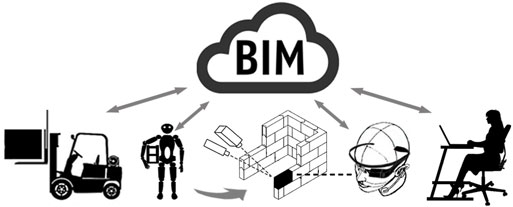

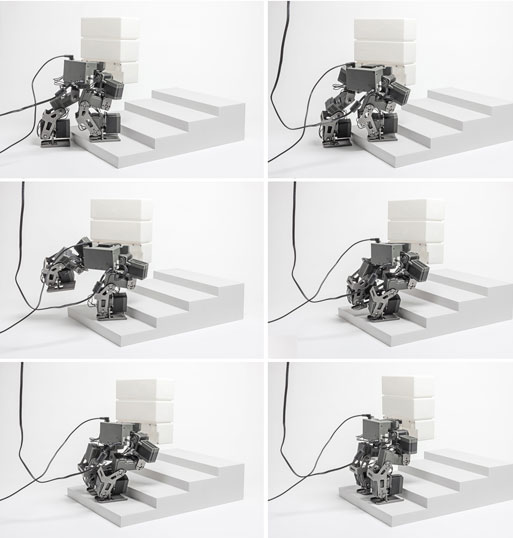

These automated assistants could potentially operate in pairs or in small, wirelessly coordinated swarms, following instructions stored on a remotely accessible Building Information Model (BIM). By leveraging fast computers and on-board sensors, our machines will be able to walk up stairs, crawl and climb ladders (see a walking prototype at www.youtube.com/watch?v=LPedOJjZAyY).

Humanoids have a key advantage over conventional construction equipment, because they can more easily maneuver through tight spaces and manipulate tools originally designed for people. Far from being rendered extinct by technology, masons could improve their productivity and acquire new skills as operator/programmers capable of enhancing the behavior and operating capabilities of their tools.

Ancient materials like masonry could take on a new life, while assuming more complex and efficient configurations. What’s more, the health risks associated with jobs like mason tending or non-standard block sorting could be mitigated by the introduction of these smart, co-robotic systems.

Just as new industries fuelled the rise of Modernism in the early-20th century, the inevitable development and potential ubiquity of autonomous and semi-autonomous technologies implies the need for a critical assessment of a how the building design and construction industry will change over time.

Along these lines, we can point to a series of important shifts in computer-aided manufacturing that are just now coming into focus.

| Old | New | |

| Robotics (isolated from people) | Co-robotic (interacts with people) | |

| Indoors | Indoors and Outdoors | |

| Fixed in-place/wheeled | Peripatetic Mobility | |

| Low Autonomy | High Autonomy |

Mike Silver directs a multidisciplinary design laboratory based in New York City. In collaboration with mathematicians, computer scientists and engineers, his office has worked at a variety of scales and has extensive experience in the design of furnishings, consumer products, robots and buildings. Silver’s work has been exhibited at the New Museum of Contemporary Art in Manhattan, the IDC in Nagoya Japan, the National Building Museum in Washington, D.C., the Architecture League in New York and Cooper-Hewitt National Design Museum. He built his first working robot out of Scotch tape and Spirograph parts at age 12. He can be reached at mike.s.silver@gmail.com.

Project Credits: Construction Site Robotics Lab (CSRL) Ball State University – Faculty: Mike Silver, Mahesh Daas Ball State University, Josh Vermillion and Josh Coggeshall. BSU Students: Yevgen Monakhov, Jason Foley, Matthew Fullenkamp, William Zyck, Justin Krasci, Michael Bolatto, Tyler Cox, Glenn Cramer, Robert Cichocki, Antone Sgro, Derek Anger, Tianxia Peng, Derek Newman, David Smith, Yao Xiao, Mathew Wollak and Thomas Friddle.

University of Buffalo Team – Faculty: Mike Silver, Karthik Dantu, and Nils Napp Students: Colin Jacobs, Tim Ruhl, Albis Del Barrio, David Heaton, Gary Chung, David Lin, Georine Pierre, Rob Miller, Johnny Lynch, Dan Fiore, Dylan Burns, Jia Jian Feng You, and Marc Velocci. Photos courtesy Paul Qaysi.