Mast Climbers

New Initiatives in the Mast Climber Industry

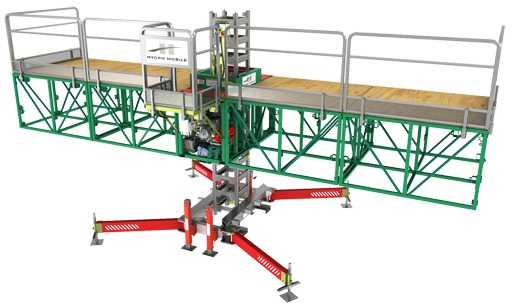

Shown is the P Series Single Mast Unit.

Canadian mast climber manufacturer Hydro-Mobile is using the World of Concrete trade show as a springboard for new initiatives designed to raise performance levels in the industry. The company will create a new ethos within its dealer network and an increased perception of mast climbing work platforms, in general.

Hydro-Mobile will be exhibiting key products from its range and highlighting both major product improvements and a groundbreaking new product. The updated M2 and P ranges will be represented at the show and will feature important product updates, and Hydro-Mobile will be announcing the new S series, an electric rack and pinion drive unit which provides up to a 60-foot-long platform on a single mast, with climbing speeds of up to 30 feet per minute and the ability to lift 8,000 pounds at 50-foot platform length and 13,000 pounds at a twin mast platform length of 120 feet.

Hydro-Mobile equipment will be present at the Spec Mix BRICKLAYER 500 competition. The company is a platinum sponsor of the event, having taken part in the regional competitions leading up to the main event at World of Concrete.

Vincent DeQuoy, president of Hydro-Mobile, is excited about 2014 and beyond. “We have the team in place to take us forward, we have the desire to make it happen, we have the distribution to make it happen, and we have the products to make it happen,” he says.

S Series Single Mast to 60 Feet Long

Hydro-Mobile, like all other mast climber manufacturers, was hit hard by the recession and has worked hard to maintain a strong nucleus of expertise and experience to facilitate post-recession growth.

DeQuoy continues, “We had to take some tough decisions in the past few years, like everybody else, but what is extremely important for Hydro-Mobile is that we managed to keep our management team intact and in AGF we found an investment partner who had faith in our team. These will be critical success factors as we move forward. Hydro-Mobile is extremely proud of its association with the masonry industry and we look forward to meeting up with many old friends in Las Vegas.”

Hydro-Mobile sees the importance of giving back to the industry, and DeQuoy explaines the ethos: “In addition to providing strong support for the SAIA and taking an active role in the ANSI committees for mast climbers and transport platforms, Hydro-Mobile has recently become a member of IPAF, with the intention of providing comprehensive industry and manufacturer training throughout its international and domestic markets.

|

|

| P Series Compact for Transport |

“This represents a major commitment to increasing quality and training levels within the industry,” he continues. “A manufacturer whose name is synonymous with contributing to improvements for the industry in which it operates maintains a high level of credibility. Additionally, our distributor network is enthusiastic about the challenge ahead, and it’s been extremely gratifying to work with committed, professional mast climber people who want to raise the bar.”

A new addition

The company recently announced that Kevin O’Shea has joined the team as director of safety and training. O’Shea is chairman of the SAIA Mast Climber Committee, member of both the A92.9 and A92.10 ANSI committees, and a key member of the SAIA/OSHA Alliance team. He is known around the world as an industry expert and is the recipient of a number of awards, including International Safety Champion and SAIA Outstanding Council Chairperson.

O’Shea is excited about the challenge ahead: “I’ve spent the last 10 years raising awareness, expertise and knowledge about mast climbers within the industry bodies, with users, with owners and with regulators, and there is still a lot of work to do,” he says. “Hydro-Mobile is equally committed, and it’s exciting to be part of such a vibrant, forward-thinking team. It’s an important time for the mast climber industry; the market is improving and equipment owners need a lot of training, advice and support to be able to manage their liabilities as they strive to get the most out of a fleet of equipment which is ageing, or cannibalized, or improperly serviced and inspected, or all three.

“Additionally,” he continues, “many experienced industry personnel have been lost in the last few years, and it’s imperative for equipment owners that the use, installation and dismantle, and maintenance is carried out by properly qualified staff. Hydro-Mobile is absolutely committed to working with its customers and distributors to provide support in these areas. What our distributors do and how they do it reflects on us, so it’s vital that we work to maintain the consistency and quality of our distributor network.”

The company places great emphasis on highlighting the local support provided through its distribution network, and Hydro-Mobile hopes that a comprehensive approach will appeal to potential customers and new distributors.

The company also will be highlighting its new website, which will be introduced in early-2014, featuring enhanced access and assistance for customers and distributors.

The Equipment Leasing and Finance Association (ELFA), the trade association representing companies in the equipment finance sector, has released three new resources to help businesses take advantage of the benefits of equipment finance.The multimedia resources – a video, a digital toolkit and an infographic – highlight how companies can use leasing and financing to acquire the equipment they need to operate and grow.

“There’s a reason that seven out of 10 companies lease or finance their equipment; it makes good business sense,” says ELFA President and CEO William G. Sutton, CAE. “We are pleased to present a new video, toolkit and infographic to answer questions companies may have about acquiring equipment and to help them get started on the road to equipment finance. As all three resources point out, equipment finance is not only a smart and flexible equipment solution for businesses, it’s also an engine for U.S. economic growth, fostering innovation, supporting manufacturing and creating jobs.” For more information, visit www.EquipmentFinanceAdvantage.org. |

| Telehandler to Watch |

Manitou Americas Inc.,??a rough-terrain material-handling equipment company,??has released its MT Series Premiere Telescopic Handlers to the??North American??market. The MT Series Premiere Telescopic Handlers bring comfort and safety to the jobsite. Four models – MT 1440, MT 1840, MT 1840 A, and MT 1840 H – offer premium features, like the JSM “Switch and Move” joystick, multi-function display, and a spacious cab. Front stabilizers are standard. Other features include transmission options; 360-degree visibility; a spacious, ergonomic cab; and compact size. Manitou Americas Inc.,??a rough-terrain material-handling equipment company,??has released its MT Series Premiere Telescopic Handlers to the??North American??market. The MT Series Premiere Telescopic Handlers bring comfort and safety to the jobsite. Four models – MT 1440, MT 1840, MT 1840 A, and MT 1840 H – offer premium features, like the JSM “Switch and Move” joystick, multi-function display, and a spacious cab. Front stabilizers are standard. Other features include transmission options; 360-degree visibility; a spacious, ergonomic cab; and compact size.

For more information, visit www.manitou.com. |

| Product Watch |

The SafeTower mobile scaffold with the QuiXSafe meets the growing need for safe working at all heights. The QuiXSafe is a system with a retractable, ergonomic brace that enables the mobile scaffold to be assembled from the inside, out. That makes it safer to assemble than conventional scaffolds. In addition, the integrated ladder system provides access and freedom of movement between levels. And, the closed, flat design of the brace clamps keeps them from falling over and causing damage.With the QuiXSafe, diagonal braces are a thing of the past. No matter the desired work height, four horizontal braces are all you need. By integrating stairs into the vertical frame, XSPlatforms makes moving between levels safe and fast. The SafeTower mobile scaffold with the QuiXSafe meets the growing need for safe working at all heights. The QuiXSafe is a system with a retractable, ergonomic brace that enables the mobile scaffold to be assembled from the inside, out. That makes it safer to assemble than conventional scaffolds. In addition, the integrated ladder system provides access and freedom of movement between levels. And, the closed, flat design of the brace clamps keeps them from falling over and causing damage.With the QuiXSafe, diagonal braces are a thing of the past. No matter the desired work height, four horizontal braces are all you need. By integrating stairs into the vertical frame, XSPlatforms makes moving between levels safe and fast.

The SafeTower is T??V certified and exceeds safety standard EN 1004:2005. The mobile scaffold provides greater stability with fewer parts. It delivers on the XSPlatforms quality guarantee. Besides offering an immediate safety solution that prevents falls from height, the SafeTower also guarantees safety in the long term, by preventing physical overexertion. SafeTower prevents physical strain through its simplified assembly method and integrated ladder. For more information, visit www.safescaffold.com. |

| Cranes |

The MagnaShear motor brake from Force Control Industries uses oil shear technology, providing long service life, even in applications like the frequent start/stop cycles seen on cranes, hoists, winches, and other overhead material handling equipment.The oil shear technology transmits torque between lubricated surfaces, thereby eliminating wear on friction surfaces. A patented fluid recirculation system dissipates heat, which eliminates heat build-up – the most common problem in dry braking systems.?? Elimination of the wear increases service life and eliminates adjustment, which also elongates maintenance intervals. An anodizing plant cut preventative maintenance by two hours per week and eliminated $8,000 in annual parts expenditures by switching from dry brakes to MagnaShear motor brakes, says Force Control. They are ideal for applications where the motor is reversed each cycle such as cranes, winches and hoists as well as loader/unloader conveyors, rail car spotters and dumpers, ship and rail car loading conveyors, trippers and pallet return conveyors. The MagnaShear motor brake from Force Control Industries uses oil shear technology, providing long service life, even in applications like the frequent start/stop cycles seen on cranes, hoists, winches, and other overhead material handling equipment.The oil shear technology transmits torque between lubricated surfaces, thereby eliminating wear on friction surfaces. A patented fluid recirculation system dissipates heat, which eliminates heat build-up – the most common problem in dry braking systems.?? Elimination of the wear increases service life and eliminates adjustment, which also elongates maintenance intervals. An anodizing plant cut preventative maintenance by two hours per week and eliminated $8,000 in annual parts expenditures by switching from dry brakes to MagnaShear motor brakes, says Force Control. They are ideal for applications where the motor is reversed each cycle such as cranes, winches and hoists as well as loader/unloader conveyors, rail car spotters and dumpers, ship and rail car loading conveyors, trippers and pallet return conveyors.

The oil shear technology also provides a smooth, cushioned stop that reduces shock to the drive system, further extending service life of downstream components. The totally enclosed MagnaShear brakes are impervious to moisture, dirt and dust common in concrete block plants as well as asphalt shingle manufacturing, coal, bulk materials handling and forest products manufacturing.

MagnaShear motor brakes feature quick-mount features for quick and easy mounting to drive motors in NEMA frame sizes 56 to 449. They are shipped ready to install, with no assembly or adjustments required, and are available pre-mounted on a motor for severe duty applications.?? MagnaShear motor brakes can be furnished to fit a NEMA or IEC frame motor, as a complete motor and brake assembly, or to mount on a machine frame or other special mounting configuration. The motor brakes are totally enclosed from outside contaminants, with seal integrity for harsh and washdown environments.?? A modular design/assembly allows for ease of servicing and maintenance. For additional information, visit www.forcecontrol.com. |