4 THINGS TO KNOW ABOUT FALL PROTECTION AND SCAFFOLDING

Words: Isa Stein

Sponsored By

In the ever-evolving landscape of workplace safety, few considerations are as critical as fall protection and scaffolding safety. As industries continue to expand and construction projects reach new heights, the need to ensure the well-being of workers at elevation becomes vital. Scaffolding, the temporary structures that provide access and support during various tasks, presents unique challenges when it comes to fall protection. This article highlights four key practices for fall protection and scaffolding that enhance safety, minimize risks, and save lives.

1. HEIGHT AT WHICH FALL PROTECTION IS REQUIRED FOR SCAFFOLDING

According to OSHA regulations, workers must follow OSHA 1926 Subpart L and use fall protection when operating on scaffolding platforms that are elevated at a height of 10 feet or more. This requirement is designed to prevent falls that could lead to serious injuries or fatalities. Scaffolding requirements are not to be confused with OSHA Subpart M, the requirement for fall protection when working at six-foot heights in the construction industry. Different types of scaffolding may warrant varying degrees of fall protection, emphasizing the importance of understanding these requirements for different projects.

Scaffolding heights can vary greatly based on the nature of the work, the industry, and the structure being worked on. Whether it’s constructing high-rises, conducting maintenance on bridges, use in masonry, or other industries, the height requirement for fall protection remains a steadfast rule that safeguards workers’ lives.

READ MORE: What Fall Protection is Required When Working on a Scaffold?

2. MOST COMMON METHODS FOR ACHIEVING FALL PROTECTION COMPLIANCE FOR SCAFFOLDING

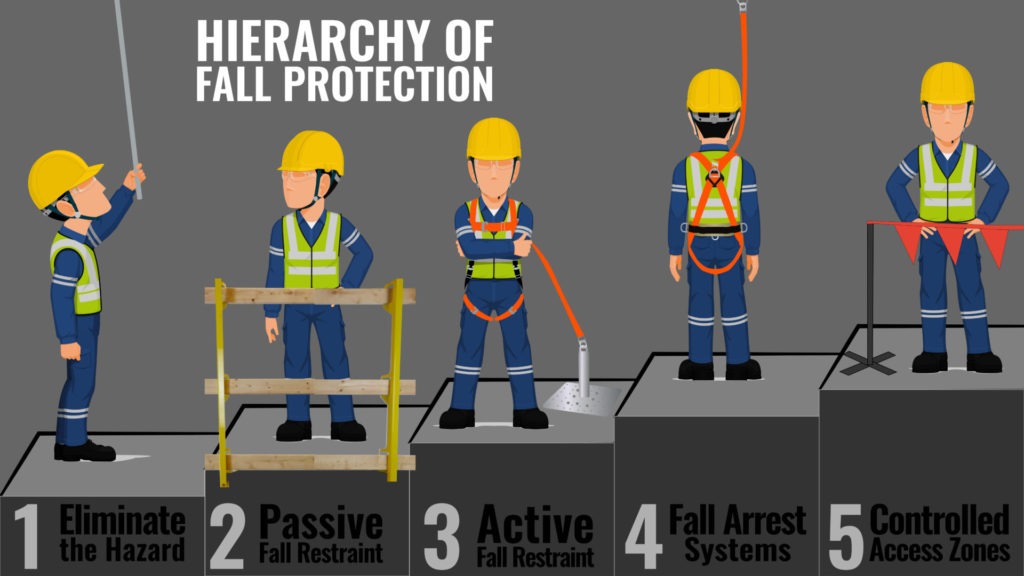

Compliance with fall protection requirements is non-negotiable, and adopting the right methods is key to achieving it. It is important for workers to follow the hierarchy of control. Eliminating a hazard is always top priority but use of scaffolding poses a fall hazard at heights above foot-level, therefore removing elimination as an option.

Workers can achieve passive fall protection without a personal fall arrest system (PFAS). The most common method for passive fall protection is the use of guardrails to protect all edges of a work area. Guardrails and toeboards act as barriers that prevent accidental falls from scaffolding platforms. These protective measures are a critical first line of defense against fall incidents. OSHA mandates that scaffolding with open sides and ends located 10 feet or more above a lower level must be equipped with a guardrail system on all sides that aren’t adjacent to structures.

When determined it is not feasible to protect all edges of scaffolding with a guardrail system, workers are required to use a personal fall arrest system (PFAS). PFAS, including harnesses, lanyards, and anchor points, are instrumental in safeguarding workers from falls. These systems arrest the fall mid-air, preventing the worker from hitting the lower surface. There are two considerations regarding working with the use of a personal fall arrest system:

Active Fall Restraint- Workers wear a full body harness and complete personal fall arrest system utilizing a restraint method that is too short to allow workers to fall outside of the scaffolding.

Active Fall Arrest- When restraint is not an option, workers utilize a full personal arrest system utilizing an SRL or lanyard to catch a fall if an accident occurs.

READ MORE: The Hierarchy of Fall Protection

When working on scaffolding, finding an anchorage solution while working at heights can be difficult. First, you must look at the nearby building or structure and determine if it could be a tie-off solution. If not, workers may resort to scaffolding for tie-off anchorage. However, when planning to use the scaffolding to tie-off workers must consult with the scaffolding manufacturer to determine if it can support the forces of a fall.

To ensure the efficacy of PFAS, proper training in their correct usage and maintenance is necessary. Comprehensive training and vigilant supervision are cornerstones of effective fall protection on scaffolding. Workers must be educated about assembling, using, and dismantling scaffolding accurately. Supervisors play an instrumental role in enforcing safety protocols, overseeing work practices, and addressing potential hazards.

READ MORE: A Guide to Scaffold Use in the Construction Industry – OSHA

3. TRADES WITH SPECIAL CONSIDERATIONS - MASONRY

Certain trades necessitate specialized approaches due to their unique challenges when working on scaffolding at heights.

Masonry Industry: Masonry tasks often involve heavy materials, intricate work, and the need for stable platforms. It’s crucial to ensure that scaffolding is properly anchored and can support the weight of materials and workers. Masonry scaffolding is made up of many components; up-rights, out-rigors, cross-bases, and base plates but lack mudsills, planks, or railings. Often the addition of railings, planks, and mudsills leaves a gap for workers to complete tasks, creating a fall hazard.

With the masonry industry, scaffolding often has three sides of protection. Workers must use the next level up as adequate fall protection, work in active fall restraint with a horizontal lifeline and a lanyard that prevents them from falling or create an overhead anchorage system that allows them to complete their work.

4. REQUIRED DOCUMENTATION FOR FALL PROTECTION AND SCAFFOLDING

Effective documentation serves as a backbone for fall protection and scaffolding safety. Proper record-keeping not only ensures compliance but also provides a roadmap for training, inspections, and continuous improvement. Essential documentation includes:

Inspection Records: Regular inspections, before initial use, after alterations, and periodically during use, are crucial. These records detail findings, actions taken, and signatures of responsible personnel. Rigorous inspection protocols detect potential problems before they escalate into hazards.

Training Records: Maintaining accurate training records is vital. These records should detail who received training, the date of training, topics covered, and the trainer’s name. As regulations evolve and new employees are onboarded, consistent training updates are pivotal.

Fall Protection and Rescue Plans: For intricate projects, a comprehensive fall protection plan outlines protocols, measures, and equipment to be employed. This living document aids in managing risk and ensuring uniform safety practices across various work sites.

READ MORE: 1926.451 – General Requirements

Fall protection and scaffolding safety are essential components of a comprehensive safety strategy, particularly in industries where working at heights is common. Adhering to OSHA regulations, implementing effective fall protection methods, considering trade-specific challenges, and maintaining meticulous documentation are paramount. By embracing these principles, safety professionals and workers contribute to a safer work environment, reducing the occurrence of fall-related incidents and promoting the well-being of everyone involved. Always remember to refer to official sources and stay updated with the latest guidelines to ensure the highest level of safety standards in scaffolding operations. In this way, we collectively create workplaces where lives are prioritized, and accidents are minimized.