What to Know Before You Build

Words: Jeff Tew

Words and Photos: Jeff Tew, Director of Technical + Training, Westlake Royal Stone Solutions

Sponsored By

As a professional, getting to a project site and realizing that a project detail has changed, rendering you unprepared for the work ahead, is just about the worst feeling in the world. Even when you have a highly trained team of people working alongside you, that pit in your stomach won’t go away quickly. It also makes the days feel longer and leaves you wondering if you could have done a better job with more preparation.

It’s important to review the details of the building code and any product-related standards before starting a new project.

It’s important to review the details of the building code and any product-related standards before starting a new project.To keep that sinking feeling in your gut from returning on your next project, here are a few tips and pointers for preparing well when planning for a stone veneer install:

1. Know the Code: Before starting any new project, it is crucial to review the building codes and regulations specific to the area where the project will be located. Each jurisdiction may have different requirements for the installation of stone veneer, including specifications regarding attachment methods, flashing, weather resistance and fire safety. Always be sure to familiarize yourself with the local codes to avoid any compliance issues during inspections.

In the case of stone veneer, ASTM International (ASTM) has developed two specific standards that contractors should be familiar with when working with manufactured stone veneer. ASTM C1780 provides guidelines for the installation, and ASTM C1670 provides guidelines for the testing and performance of adhered manufactured stone masonry veneer. ASTM C1780 covers important aspects of stone veneer installation, including surface preparation, weather resistance, flashing, attachment methods, mortar selection and application. Contractors should review this standard to understand the recommended practices and requirements for a compliant installation. ASTM C1670 provides clear testing and evaluation methods that a manufacturer can test to make sure their product is code compliant. When a contractor selects a stone that is certified to meet ASTM C1670, they can rest assured they are using a code approved material.

By adhering to ASTM C1780 and using product certified to meet ASTM C1670, you ensure that your stone veneer installation meets industry standards. Following these guidelines will help prevent common installation errors and material issues due to incorrect manufacturing. Familiarizing yourself with these standards is an essential step to ensure compliance and deliver high-quality workmanship to your clients.

MSV brands that have been certified through the NCMA’s Research and Development Laboratory have been thoroughly tested for various factors related to performance and durability.

MSV brands that have been certified through the NCMA’s Research and Development Laboratory have been thoroughly tested for various factors related to performance and durability.2. Be Fully Product Aware: There are various types of stone veneer available in the market, including a growing assortment of natural and manufactured stone veneer products in numerous styles. Researching and understanding the specific characteristics, installation requirements and maintenance recommendations for the chosen stone veneer product is essential. Consider factors like weight, size, thickness, color options, durability and compatibility with the project requirements, and be sure to consult with suppliers and industry experts to gain a comprehensive understanding of the product you will be working with.

Another recommendation is to only use products that have undergone third-party testing and verification. These tests, conducted by independent labs, help to ensure that the products meet ASTM C1670 standards for quality, performance and safety. One such verification process is provided by the National Concrete Masonry Association (NCMA). The NCMA Research and Development Laboratory testing and certification process involves rigorous examination of stone veneer products to assess their compliance with specific criteria related to product requirements, performance, and durability. This process evaluates factors such as compressive strength, freeze-thaw durability, water absorption and density, dimensional tolerances and shear bond. By choosing products that have undergone this certification process, you can have greater confidence in their suitability and durability for the intended application.

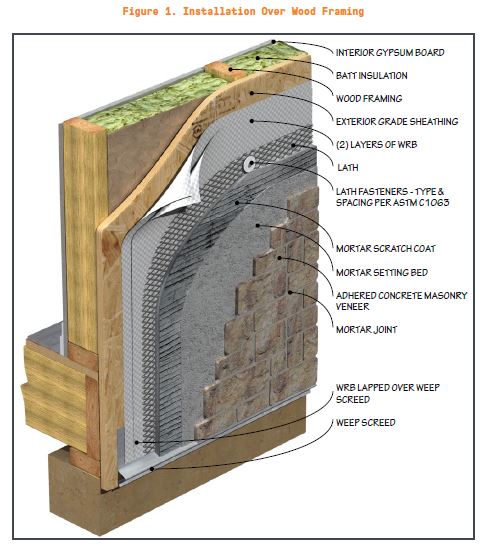

Preparing in advance includes doing research on the type and number of WRBs, as well as flashings, weep screeds and other drainage provisions.

Preparing in advance includes doing research on the type and number of WRBs, as well as flashings, weep screeds and other drainage provisions.3. Determine Substrate Compatibility: Assessing the compatibility of the existing substrate with the chosen stone veneer is crucial for a successful installation. Evaluate the condition, stability and load-bearing capacity of the substrate. It is essential to ensure that the substrate is structurally sound, properly prepared and capable of supporting the additional weight of the stone veneer. In cases where the substrate is unsuitable, additional measures such as reinforcement or substrate replacement may be necessary.

4. Plan for WRBs and Drainage: Proper water-resistive barriers and drainage are critical for the long-term performance and durability of stone veneer installations. Research the recommended type of WRBs and number of layers of WRB, flashings, weep screeds and drainage provisions specific to the location of the project and the stone veneer product being used. These measures will help prevent moisture infiltration, potential water damage and the accumulation of mold or mildew behind the veneer. The use of a rainscreen or a drainage plane behind your stone veneer project may be required by code in some areas and can be a benefit to any project.

5. Consider Expansion and Contraction: Utilize a soft joint at any transition from the stone veneer system to other materials to help prevent bulk water intrusion behind the claddings. Stone transitions to windows, doors, HVAC, electric, and any vertical transition to other claddings are just a few of the areas that would benefit from the use of a soft joint. While stone and mortar are fairly stable, products made from metal, wood, plastics and vinyl will expand and contract, resulting in a large crack or opening between the dissimilar materials. A good transition from your stone system to other materials will help keep water out and prevent damage from dissimilar material movement.

A Word on Working With Clients

Savvy clients ask questions, often because they want to remain involved in the process. The more prepared you are to answer them, the more likely you are to gain their confidence and leave them pleased with the results. Clear communication and collaboration throughout the process will help you understand your client’s aesthetic preferences, design goals and functional requirements.

Clients value collaboration and often relish the opportunity to be involved at various stages of a project, from start to finish.

Clients value collaboration and often relish the opportunity to be involved at various stages of a project, from start to finish.

In the event that you’re taking the lead on any part of the client interaction and planning process, here are some key steps to foster a successful collaboration:

- Initial Consultation: Begin by discussing the client’s vision, desired style and any specific ideas they may have. Take note of their expectations regarding colors, textures, patterns and the finished aesthetic they want to achieve.

- Presenting Samples and Options: Provide the client with samples, allowing them to see and feel the textures and colors firsthand. A pro tip is to have the customer view the samples next to the claddings and colors near which the stone will be installed, and particularly in the same lighting conditions it will be viewed in. Be sure to explain the various options available and offer guidance based on their preferences. Avoid selections based only on brochure or website photos as color and texture are not represented nearly as well as a physical sample of the stone.

- Mock-ups: Installing a 4- to 8-square-foot mock-up helps the client visualize how the stone veneer product will look in their space once installed. This step allows for any necessary adjustments or modifications to align with the client’s vision. An agreed upon mock-up allows both owner and contractor to know what aesthetics will be acceptable on the project and minimize or eliminate disagreements during or after installation.

- Collaboration on Installation Details: Involve the client in decisions regarding stone placement, joint sizes and other installation details. This collaborative approach ensures that the final result matches their envisioned outcome.

The best way to keep clients engaged is to involve them in key decisions, including multiple onsite walkthroughs.

The best way to keep clients engaged is to involve them in key decisions, including multiple onsite walkthroughs.- Regular Communication: Maintain open lines of communication throughout the project, providing updates on progress and addressing any questions or concerns the client may have. Seek their input and feedback at critical stages to ensure alignment with their expectations. This is especially important in high traffic, high visibility areas like entry ways.

- Final Walkthrough: Conduct a final walkthrough with the client upon project completion. This allows them to inspect the finished stone work and provide feedback. Address any minor adjustments or touch-ups as needed to ensure complete satisfaction.

By actively involving customers in the decision-making process, you will encourage a sense of ownership and collaboration that enhances their satisfaction in the finished project while also helping you and your team build a positive reputation.

Worth the Effort

Preparing for a new project requires thorough research and an ongoing attention to detail. By reviewing building code requirements, researching the products you’ll be working with and executing effectively on the job site, you can ensure a successful and durable installation. Remember, proper preparation and adherence to best practices will not only guarantee client satisfaction but also protect your reputation as a professional contractor in the industry.

Perhaps most important of all, you’ll feel fully prepared, competent and confident throughout the process.