The Perfect Fit: Masonry Tool Handle Types

Words: Mackenzie Claassen, Content Writer/Editor at MARSHALLTOWN

Photos: MARSHALLTOWN

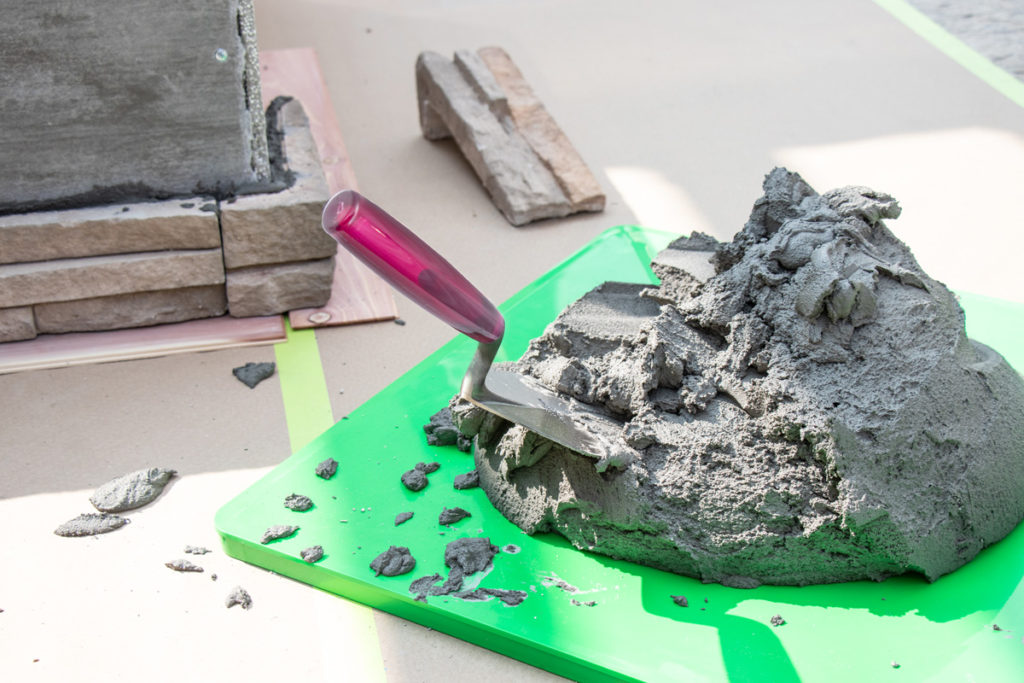

The masonry trade has been around for thousands of years and is one of the oldest in history. The tools used back then have evolved over time into stronger, more innovative versions of themselves today and are offered in a variety of styles and sizes. Choosing the best trowel for your masonry job is important, as each trowel serves a different purpose. Equally important is choosing the best handle grip for your trowel. After all, you will be spending a lot of time gripping this tool.

There are five main handle grip styles, each having its own benefits. What it really comes down to is user preference — which handle grip do you believe will provide you with the most comfort, support, and balance?

Wooden

Of all the handle types, wooden handles have been around the longest. Stonemasons have used this handle grip for almost 12,000 years; it is the traditional option and is even preferred by many masons today. Wooden handles are long-lasting and offer a smooth grip. One benefit is they can be easily shaped during manufacturing to fit the contours of the human hand.

Unfortunately, wooden handles can be uncomfortable when used for an extended period of time, plus they are more susceptible to moisture damage than other handle types. This can lead to splitting, resulting in the need for a replacement handle.

Plastic

Plastic handles are a common alternative to wooden handles. This type of handle is attractive to masons because of its easy grip and crack-resistant construction. The plastic material also makes for easy cleaning when your trowel gets messy with mortar and other materials. The downfall of plastic handles is like that of wooden handles – they can be quite uncomfortable to use for longer periods of time.

Leather

High-quality leather handles are a popular choice for block and bricklaying. These handles provide a comfortable, non-slip grip. The non-slip grip makes this handle the ideal one for working in wet weather or on a hot day when your hands get sweaty. Leather handles are aesthetically pleasing to the eye, giving off a luxurious feel while still being durable and long-lasting. To keep these trowels in pristine condition, they do need to be properly cared for. One disadvantage of this handle grip type is the cost — leather handles are the most expensive material, but the expensive price tag matches the level of quality you get with this handle type.

Soft Grip

The soft grip handle is by far the most popular handle type. Not only are soft grip handles durable and comfortable, but they are also resilient and will last a long time. The soft feel of the handle reduces user fatigue, allowing you to work longer. Another benefit of a soft grip handle is increased user control making for a safer experience. With a firm, comfortable feel, it is easy to see why this handle type is so popular among masons.

Cork

Cork handles are a great alternative to soft grip handles and have several benefits. They have a textured, tacky feel that provides an improved grip helping to prevent blisters. Cork handles are lightweight and practically impermeable, meaning they will not absorb liquids like rain, sweat, or water. Like soft grip handles, cork handles are comfortable and durable; however, they are more expensive. But with their excellent grip and durable construction, many masons believe they are worth the price.

Overall, masonry tools have been an important part of the construction trade for centuries. As we develop new technologies and ideas, these tools will continue to turn into even stronger versions of themselves. With many types of individuals employed in the masonry industry, it is fitting to have several tool handle styles to choose from. Each has its own advantages and affects the tool differently. What it really comes down to is personal preference — which handle grip is the best for your masonry job?