Mortar and Grout: Mortar: Proportion Spec or Property Spec?

Words: Donald Alward

Figure 1. Illustration showing mortar Types M, S, N, O, and K and some of the properties that vary with mortar type.

The most commonly referenced standard for masonry mortar material in modern construction in the United States is ASTM C270 Standard Specification for Mortar for Unit Masonry. This standard describes the minimum requirements for various types of mortar used in brick, block, stone, and other masonry. The standard includes requirements for Type N and Type S mortars, which are the most commonly specified mortars in modern construction. It also includes requirements for Types M and O mortars (and used to include a Type K mortar). There is a fairly common misconception that the “S” in Type S mortar stands for “structural”, and the “N” in Type N mortar stands for “nonstructural”. This is not the case. In fact, the mortar types are every other letter in the word “masonwork” (Figure 1).

ASTM C270 has two different methods for describing the requirements for each mortar type, as described below.

The ASTM Standard

The requirements for each type of mortar are shown in ASTM C270 in two different manners: with proportion specification requirements and property specification requirements.

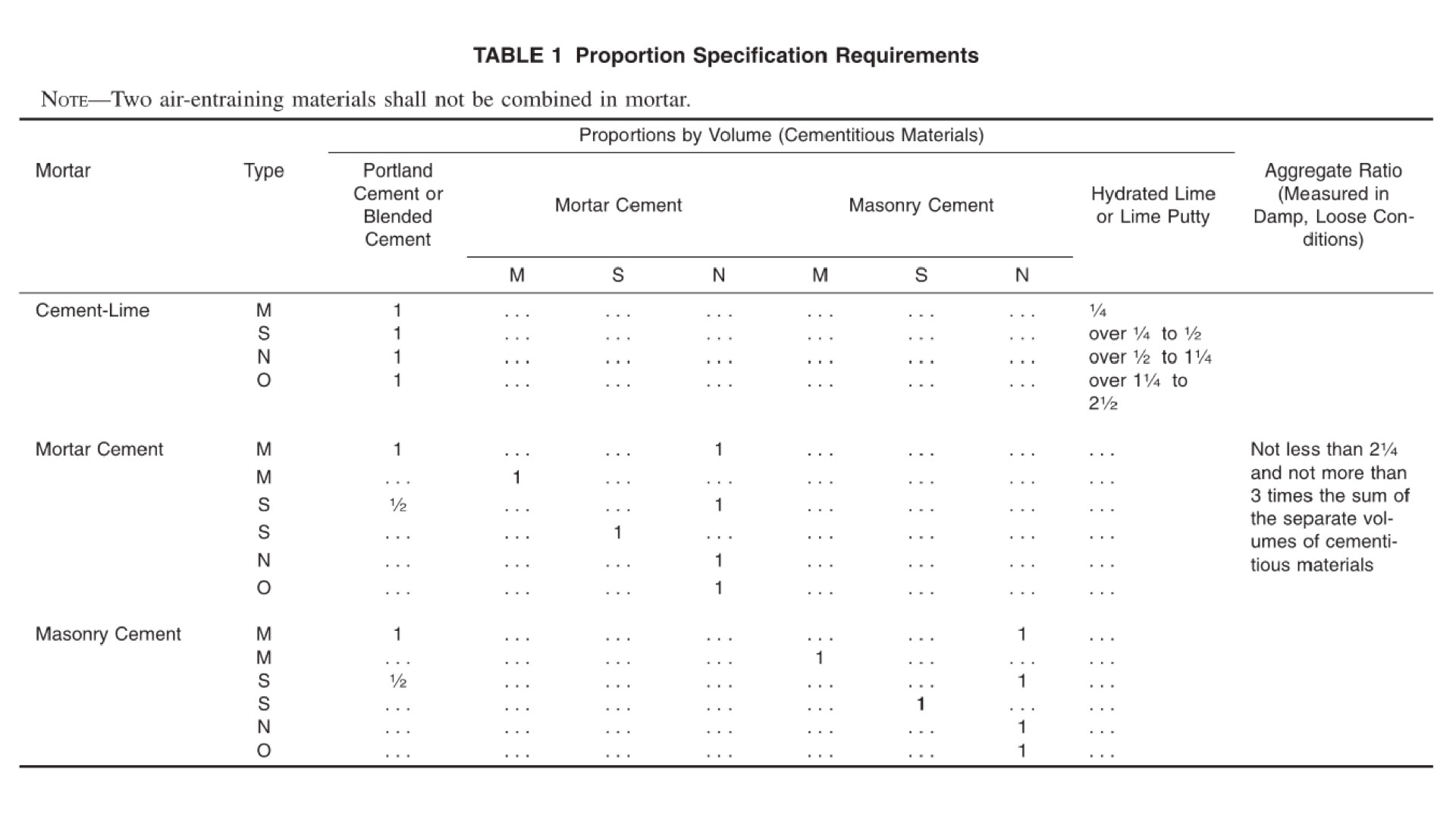

Figure 2. Table 1 from ASTM C270, showing the Proportion Specification Requirements for masonry mortar.

Proportion specification requirements list the proportions of each mortar ingredient (generally cement, lime, and sand) that are required for each mortar type. These requirements are shown in Table 1 of the Standard (Figure 2). For example, a Type N Cement-Lime mortar meeting the proportion specification requirements could be mixed with 1 cubic foot of portland cement, about 1 cubic foot of lime, and about 6 cubic feet of sand.

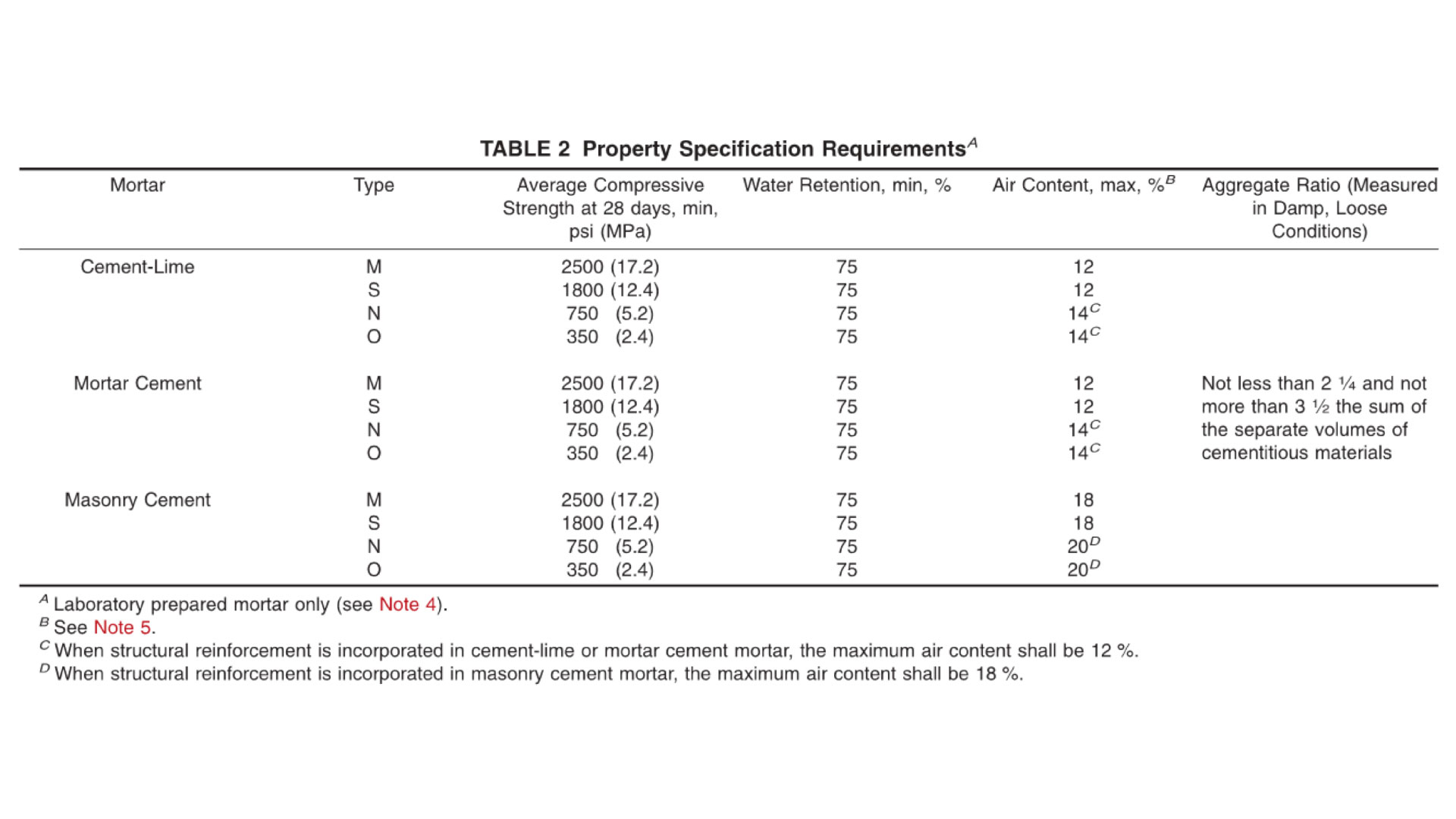

Figure 3. Table 1 from ASTM C270, showing the Property Specification Requirements for masonry mortar.

Property specification requirements list minimum and maximum material properties that are required for each mortar type. These requirements are shown in Table 2 (Figure 3). They include requirements for compressive strength, water retention, air content, and aggregate (sand) ratio. For example, a Type N Cement-Lime mortar meeting the property specification must have a minimum compressive strength of 750 psi, a minimum water retention of 75%, a maximum air content of 14%, and an aggregate ratio between 2¼ and 3½.

It should be noted that the properties described by the property specification in C270 are generally focused on material properties related to the structural performance of masonry mortars. The table does not include properties that are often most important to masons, such as stickiness and board life. Additionally, the properties listed in this table are based on laboratory-prepared mortar (Footnote A) that is very dry and not suitable for construction. Field-prepared mortar properties should not be compared to the values in Figure 3.

In general, the proportion specification is “conservative” in that mortars formulated using the proportion specification tend to easily meet the requirements of the property specifications for that type of mortar. In fact, it is not uncommon for a proportion-specified Type N mortar to meet the requirements for a property-specified Type S mortar.

Code Requirements

In general, the Building Code (TMS 402) does not distinguish between proportion and property specification mortars. If a mortar meets the requirements of Type N by either proportion or property table requirements, it is equal in the eyes of the Code.

However, the Code does require Type N or even Type S mortar in certain situations, usually related to structural loading conditions. The Code also places some restrictions on the use of Masonry Cement mortars in high-seismic applications that are not fully grouted.

Practical Implications

Just as the Code does not distinguish between proportion and property specification mortar, project specifications generally should not require mortar to meet one or the other (or both) sets of requirements.

Figure 4. View of brick masonry veneer with variable mortar color.

In the past 15 years or so, a very high percentage of mortar production has shifted from field-batched material (where the simplicity of proportion measurement makes it the dominant approach) to preblended, plant-batched material (where property specification is the dominant approach). In general, this shift has not been motivated by better structural performance or material properties of proportion-specified mortar. Rather, it has primarily been construction litigation and repair claims related to color-matching of field-batched mortar that has pushed many masons toward preblended products (Figure 4).

Since lime and portland cement tend to be the most expensive components in mortar, it is generally in the best interest of preblended mortar producers to minimize these ingredients (and maximize sand content) in order to minimize mix cost. Therefore, price competition and profit motive tend to result in property-specified mortars barely meeting minimum property requirements. Of course, suppliers must also be able to sell their products. Therefore, mix designs tend to balance the properties desired by the purchaser (typically the mason) with the minimum requirements of the ASTM standard. Additionally, the proportions of materials used in property-specified mortars generally are considered proprietary information and not disclosed to the designer or mason.

Current industry standard practice using preblended, property-specified mortar can have significant implications for usability of modern mortar in the field. In the past, on hot or dry days, a mason could tweak the mortar mix by adding additional lime to increase water retention and board life. If this additional lime did not push the mix past a proportion limit (since the proportion specification allows for a range of lime proportions), the modified mortar would still meet the proportion requirements. There was a built-in “buffer” in the proportion specifications to allow for variations of this type. However, with property-specified preblended mortars, there is often little to no “buffer” available. If additional lime, for example, is added to a property-specified Type S mortar on a hot day, the resulting mix would likely no longer meet the property (or proportion) specification requirements for a Type S mortar. Therefore, in structural applications, property-specified mortar should not be field-modified by adding lime or admixtures. This can put masons in a bind when their preblended mortar is drying out too quickly and their productivity is suffering. In many cases, batch plants will provide preblended proportion-specified mortars upon request (at a higher price). If low lime content or variable weather conditions are problematic for a project, it may be worthwhile to request a proportion-specified mortar (if available in your region), even if there is a price premium for this material.

The relatively recent transition to predominantly preblended, property-specified mortars occasionally sparks questions regarding quality assurance testing using mortar cubes. Generally speaking, the use of ASTM C780 testing of mortar cubes has become effectively obsolete with the predominance of preblended mortars. The compressive strength values obtained by C780 testing cannot be compared to the C270 tables, and their only purpose is to measure the consistency of the mortar batching process. Since the vast majority of mortars are now batched in plants using fairly precise measures and instruments, C780 testing now rarely provides any meaningful information. If physical testing for quality assurance is desired, prism testing (especially grouted prism testing) typically provides the most meaningful information on structural masonry properties.

In summary, the masonry industry has generally moved toward preblended mortars, which tend to meet property specification requirements. These materials reliably meet minimum material requirements, but they tend to be formulated with little wiggle room for field-modification.