Fire Testing: Brick, A Traditionally Non-Combustible Material

Words: Dan Kamys

Introduction: Don Foster, Founder and VP of Masonry Cosmetics

Body: Chip Clark, VP of Engineering and Research at the Brick Industry Association

Photos: BIA, Robert W. Ginn

Most of us have seen homes like the one pictured above, originally built of non-masonry products except for the brick chimney. Unfortunately, when a house like this one catches fire, everything burns to the ground. Only the masonry chimney is left standing.

The reason the chimney does not burn has to do with the fact that it is a “traditionally noncombustible material.” What does that mean? It means that it is one of the few materials that were recognized by older building codes as having “no part of the material [that] will ignite or burn when subjected to a fire.” How old of a building code are we talking about? Specifically, codes that were published before 1956 – that’s when the definition of “noncombustible” in the building code was changed by building officials to recognize materials like gypsum board as “noncombustible” even though they had a combustible layer included in them that would burn - such as a paper facing in the case of gypsum board.

To talk more about fire resistance of brick in general and to discuss the most recent fire resistance testing conducted by the Brick Industry Association (BIA) we have Chip Clark, Vice President of Engineering Services for BIA. Chip and a very talented team manage and provide an enormous amount of up-to-date technical information about brick via BIA’s Technical Notes and Brick Brief publications, through their work on the building codes and standards vital to our industry, and through their continued research on subjects such as the fire resistance test discussed below. Additionally, they are always available to review the drawings and specifications on projects with brick masonry.

Most people readily recognize that brick masonry does not burn. However, what they may not realize is that walls which include brick masonry veneer, and even thin brick masonry veneer, can provide enough protection for any combustible layers behind them so that the wall not only achieve a fire resistance rating per ASTM E119 testing, but it can also limit the spread of fire to meet the fire propagation requirements of the NFPA 285 test.

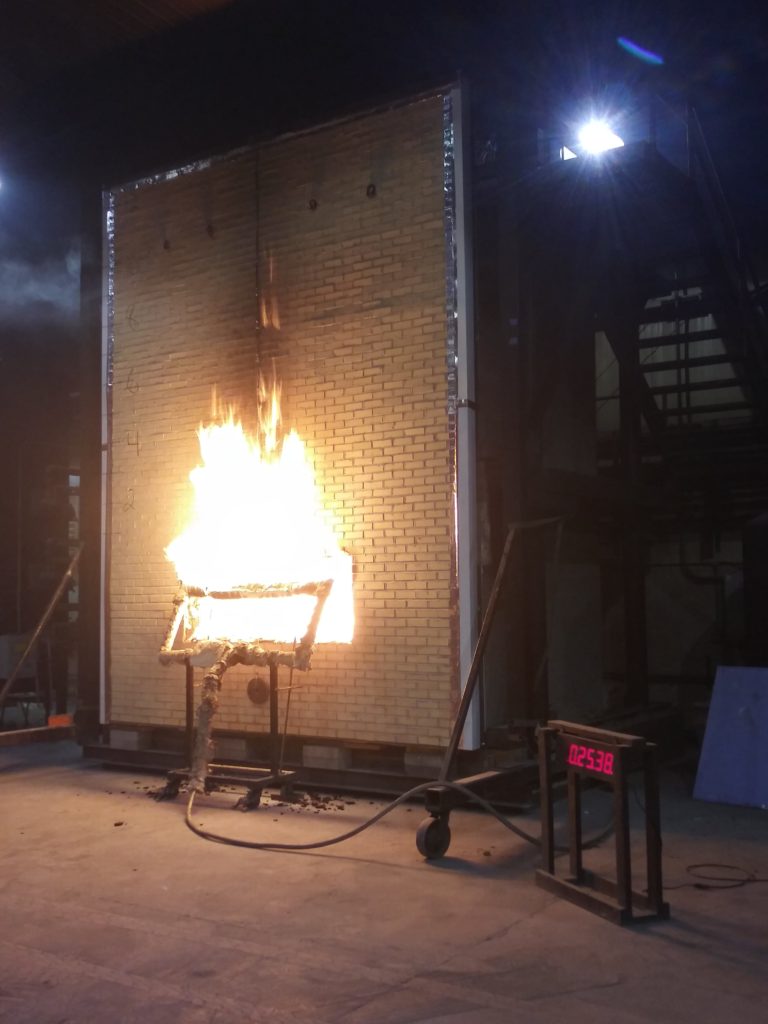

In late 2018, the BIA conducted fire tests at the Intertek Building & Construction facility in York, Pennsylvania on thin brick veneer wall assemblies. The tests demonstrated that a thin brick masonry veneer wall assembly constructed using the thin set installation method with polymer-modified mortar and filled with 4 inches of expanded polystyrene foam plastic insulation provides a one-hour fire resistance rating on both the exterior and interior sides of the wall and meets code-mandated limits on fire propagation to combustible components within the wall. In addition, based on the post-test inspection results, an Engineering Analysis Report was written by Jensen Hughes, a qualified, recognized fire safety engineering consultant. The report lists and justifies alternate materials which are permitted to be substituted for specific components within the tested wall assembly. The report also justifies that a thin brick masonry veneer wall assembly constructed using the thick set installation method will provide the same or better fire resistance and flame spread propagation performance as the wall system tested at Intertek in accordance with ASTM E119 and NFPA 285 respectively. The above reports are often cited by local building code officials as substantiation for the use of thin brick wall assemblies in buildings to provide the appropriate level of fire resistance and to meet fire propagation requirements. To document the above, Intertek wrote a Summary Fire Test Report for each of the three tests, and Jensen Hughes wrote an Engineering Analysis Report, all of which can be viewed on the BIA fire protection landing page.

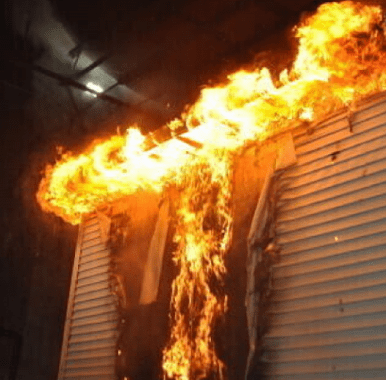

Referring back to the example of the house without masonry components except for the chimney at the beginning of the article, most people do not realize how quickly fire can spread – especially if plastic products such as vinyl siding are involved. In an experiment conducted by the Fire Safety Research Institute, three wall assemblies with vinyl siding were compared when a fire was set at the base of the wall. In the video documenting the experiment, one of the wall assemblies allowed the fire to climb the exterior wall, breach the eave and become an attic fire in less than 2 minutes. Compare that to brick masonry which does not burn and would not allow a fire to climb the wall.

In another experiment conducted by the NIST Building and Fire Research Laboratory, two wall assemblies with vinyl siding were compared where one had 1/2 in. Type X gypsum board between the siding and the OSB sheathing, and one did not. Each wall was constructed 6 feet away from an adjacent combustible exterior wall intended to simulate a scenario in which a fire occurs on the interior of one house, breaks through a window in the combustible exterior wall and catches the house next door on fire. For the wall without the gypsum board, it took less than 80 seconds for flames from the adjacent exterior wall to ignite the OSB sheathing after the window failed. In order to achieve a one-hour fire resistance rating, this type of wall has to include at least ½ inch thick Type X gypsum board behind the siding. In contrast, a nominal 4-inch-thick brick veneer can achieve a one-hour fire resistance rating from the brick alone, without considering other components in the wall assembly.

The bottom line is that brick masonry veneer, and even thin brick masonry veneer, does not burn and can provide protection for any combustible materials located behind it.

The information that Chip and the BIA have shared above is life saving and adds to the benefits that brick and masonry have to offer home and business owners. This information can also serve as talking points for architects, builders, contractors, and engineers. Building fire safety into a structure can mean survival for those who inhabit it or work there. Share the knowledge!