Protective Treatment Or Sealer: What’s the difference?

Words: Jake Boyer, Business Unit Leader, Clean & Protect Group, PROSOCO

Photos: PROSOCO, sestovic

“What’s the best sealer for my substrate?” is a question we hear all the time. But the semantics of the word “sealer” make this question a little tricky to answer, and often we see the word “sealer” used interchangeably with “protective treatment” – when actually they differ in meaning.

We always use the term protective treatments because that’s a more all-encompassing term than the word sealers, which is used inaccurately in some cases. Sealer is a term that usually relates to products that are film-forming protective treatments. Oftentimes, they’re made of acrylic, or sometimes polyurethane or even epoxy chemistries, and those products do just what the name implies – they seal the surface by creating a continuous film over that surface, with the intent of keeping anything like moisture or contamination, stains, things like that, out of the substrate.

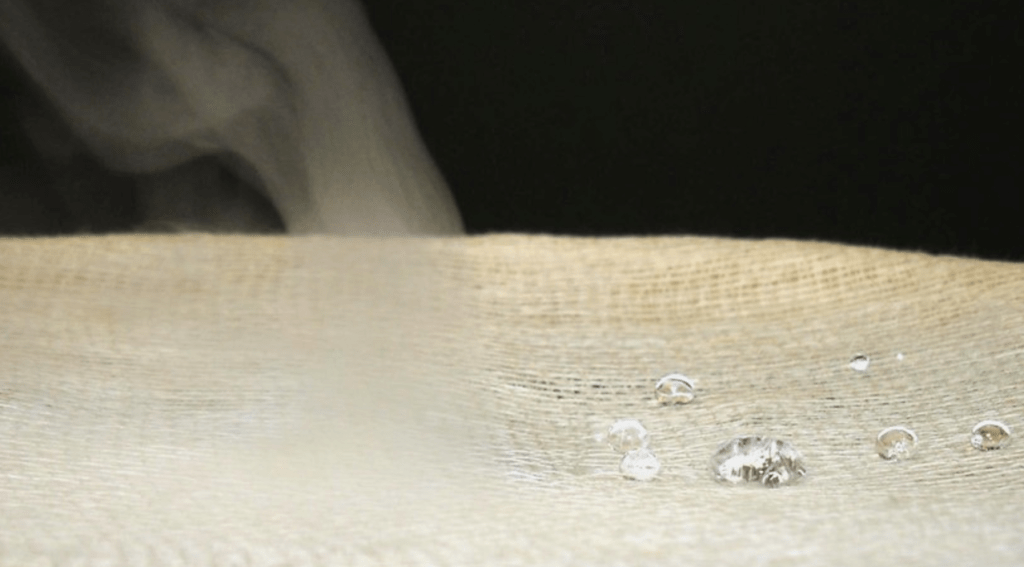

Issues can arise with sealers because of what they keep out, they can also keep in. They keep whatever is in the substrate on the inside — and that’s not always a good thing. So say you’ve got a lot of moisture trapped in a masonry substrate and apply a film-forming sealer over the top of that. That moisture is eventually going to try and work its way out, and if it comes up and hits the back of that sealer, that can cause a host of other issues.

Those issues might include sealer blush if you’re lucky. Sealer blush is the result of a non-vapor permeable sealer being applied to the surface of a substrate. Water gets behind it, whether it was already in the substrate from moisture during construction, or it got in from a small crack, missing flashing or otherwise. The water then tries to work its way out of the substrate, but hits the back edge of the sealer and condenses on the back end, turning it white — blushing. Here’s a perfect analogy: a turkey sandwich in a ziplock bag is left on a picnic table in the sun. Once it is ready to be eaten, the bag has moisture and condensation trapped inside the bag, causing it to look foggy, and the sandwich is ultimately soggy.

That’s essentially what’s happening in our walls, but at a cost, that far exceeds the price of a turkey sandwich. Keep an eye out for sealer blush, because it can be your first sign that you have moisture issues and should be a call to action before things get worse.

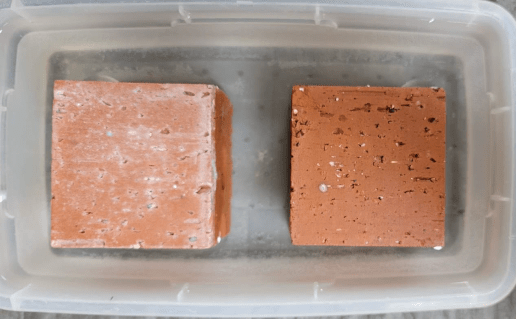

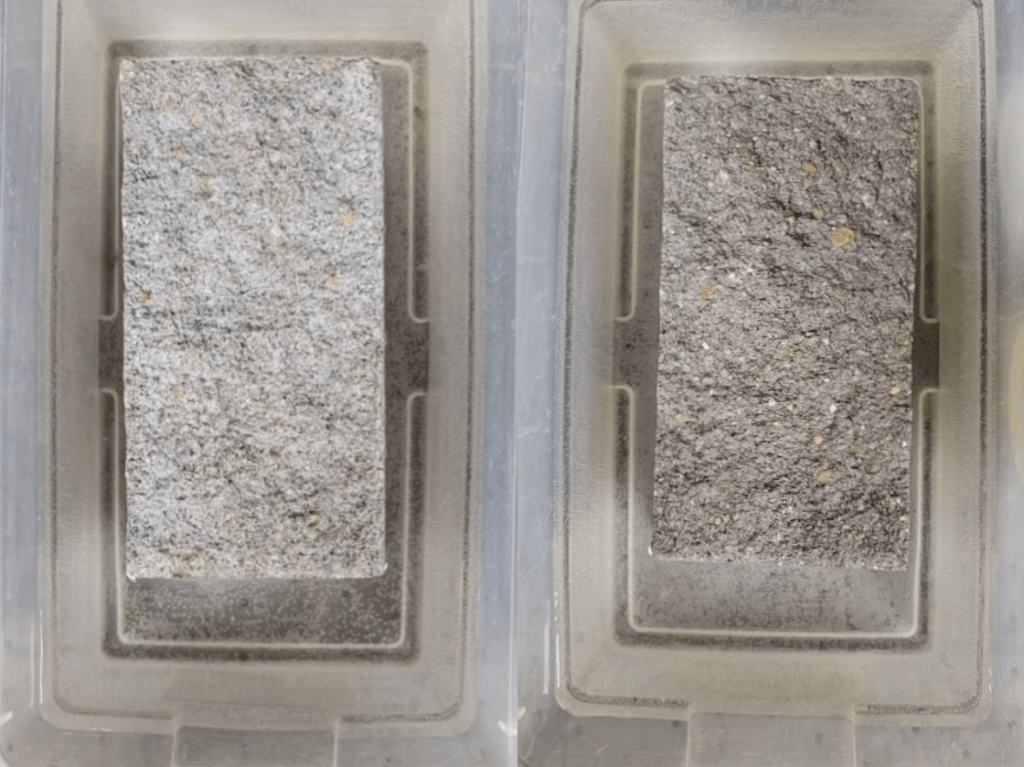

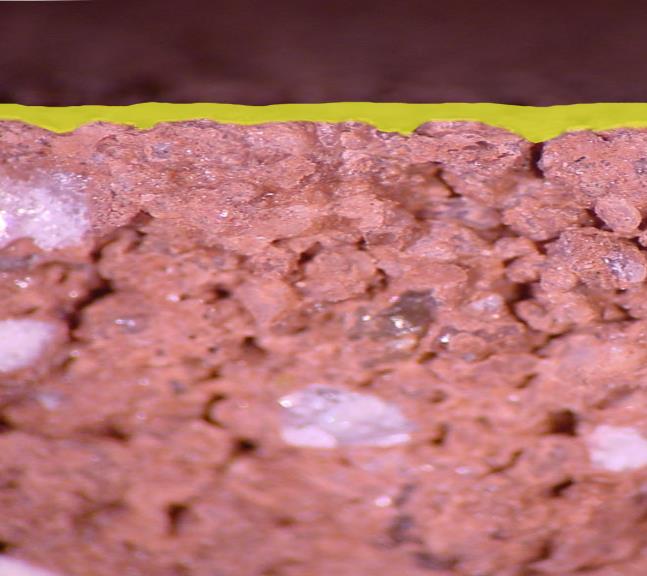

If you’re not lucky, you might get what’s called subflorescence, which is the same thing as efflorescence but it actually takes place sub-surface or inside of that substrate as that salt crystallizes and begins to expand. This can cause more problems as it then will be more likely to spall and break away the face of the masonry. Subflorescence can be prevented by having a protective treatment in place that allows the substrate to maintain its permeability or to “breathe” by keeping the liquid moisture out but allowing the smaller water vapor to escape when it does inevitably get in somehow.

The same thing is true if you’re in a climate zone with freeze-thaw conditions and moisture builds up within that substrate. Water’s one of those unique materials that actually expands when it gets colder and freezes. If that water within that substrate expands and it’s trapped within some of those small pore structures, it can cause the face of that masonry to break away or spall off. Like every rule, there are exceptions, but in general, most film-forming products don’t allow that substrate to breathe.

One thing to always remember is that nature is always going to seek equilibrium. Moisture will somehow get into your substrate. Once it gets in, have you provided it a path to get out? If you’ve applied a film-forming sealer over the top of that substrate, chances are you’ve limited that substrate’s ability to dry. You’ve altered the natural permeance of that material to where now when water and water vapor get inside, you’re not allowing them a path to get out. So a lot of the film-forming sealers can actually cause more issues than they prevent in many cases.

Of course, there are exceptions to that rule, but in most cases, the better bet is to go with a penetrating protective treatment because you get all the benefits of a “sealer” by keeping out the water, the stains, and the contamination that you’re trying to avoid penetrating into your substrate. But you also maintain the natural permeance of that material. You’re not limiting a masonry substrate’s ability to breathe or dry when water does inevitably get in.

Oftentimes, penetrating protective treatments will maintain the natural appearance of the substrate. There are, however, some that can alter that appearance by imparting some sort of color enhancement to it. If you’re looking for a gloss, that’s one of the few applications where a film-forming protective treatment may be more suited to your needs, but be sure to seek one out that has testing data to support its “breathability” or vapor permeance. There are other applications where a film-forming protective treatment is the right choice, but in general, you typically want to lean toward a penetrating, breathable protective treatment as a better choice, especially for exterior applications, because water happens.