The Mason’s Guide To Laser Technology

Words: Uma Basso

Words: Uma Basso

Photos: Kapro Tools, Stabila

Laser technology has revolutionized just about every industry. For the mason, it can change how they work on the jobsite.

Lasers were first introduced over 60 years ago and improved as technology continues to advance. Today's lasers measure distance with exceptional precision and reveal structural flaws that the naked eye cannot see. As technology continues to improve, laser equipment has become more affordable and accessible for masonry contractors.

Laser Technology Helps Masons Work Better

Laser technology has been incorporated into the equipment that masons commonly use.

Levels: Laser levels are easy to transport and measure distance with extreme precision. Some incorporate blue tooth technology, allowing results to be easily transmitted via specialized applications.

Scanners: Conventional methods to measure buildings and other environments can take days to complete. Scanners incorporate laser technology that can capture measurements in just a few minutes. Beyond measurements, laser technology can be coupled with augmented reality to produce 3D images of buildings and surfaces. This can reveal structural challenges or other surface conflicts that could lead to inaccuracies in design and reduce excess material waste.

The Impact of Laser Technology on the Jobsite

It's easy to see how laser technology has transformed the jobsite.

Improve accuracy – Lasers can measure distance and level with incredible accuracy. Innovations in laser technology have stretched their measurement distance to a half-mile.

Reduced personnel – What was once a two-person job can effectively be done by just one person. While laser equipment may seem pricey at first, reduced labor can help you recoup their costs in a short time.

Versatile – Laser technology is effective both indoors and outside. You’ll experience similar accuracy for both short and long distances.

How to Care for Your Laser Equipment

Laser tools, such as levels and scanners, are meant to be used. But as the equipment is shuffled between jobs, it could face some rough conditions. The tremor or vibration as they are moved can throw off their precision. Equipment can be dropped or knocked over on the site. They could even be subject to bad weather.

Taking care of your tools can prolong their life. Laser equipment is no different. Proper care for your laser equipment helps keep its results accurate and can extend its life.

To find out some of the best ways to care for laser equipment, we reached out to Rich Morse, Regional Sales Manager of Stabila, and Gal Wollach, VP Business Development of Kapro Tools, for some helpful hints.

Maintenance:

Morse suggests taking advantage of your slow season to check the calibration of your laser levels. Vibrations and frequent movement can throw off their precision. Calibrate your equipment regularly to ensure the laser is square and level. Skip this vital step, and you can experience costly project delays and excessive charges when it becomes an emergency.

Remove Batteries: If you aren’t using your laser equipment, take out the batteries. If it sits around for a long time, the batteries can corrode. This can damage the internal wiring harnesses and terminals. Repairs can be costly, and, in some cases, you may be looking at replacing the equipment.

Avoid Vibration: With expensive equipment, masons are typically mindful of job site accidents. Properly securing your equipment while in use keeps it from being knocked over or dropped. You may not be considering the impact that vibration and shaking have on the equipment during transport. If it bounces around in the bed of your truck, it can throw off its accuracy.

Best Jobsite Practices for Laser Equipment

Following good practices on the job site improves the equipment's precision and efficiency on the job.

According to Morse, verifying the foundation or slab is square can help pinpoint issues before you get started. If you don’t catch this early on, you can sink thousands of dollars in labor costs trying to fix someone else’s mistake.

Pay attention to your surroundings. Laser equipment that sits on a tripod may shift unexpectedly as people walk by. If placed on a muddy or soft surface, the equipment can slide. These slight movements can impact the equipment’s accuracy.

Dirt, dust, and water can interfere with a laser’s visibility. So, Wollach suggests keeping the windows of the laser clean to prevent inaccurate results. To help pick up where you’ve left off, put a control point or benchmark on the ground and wall. This gives you two reference points to use when setting up the laser equipment the following day.

Laser Levels

There are a wide array of laser levels on the market today. They are accurate, easy to use, and incorporate some of the newest technologies to improve efficiency.

Kapro Tools

Kapro features a versatile line of laser levels. They are made to withstand rough job site conditions while delivering precise accuracy and added value to the mason.

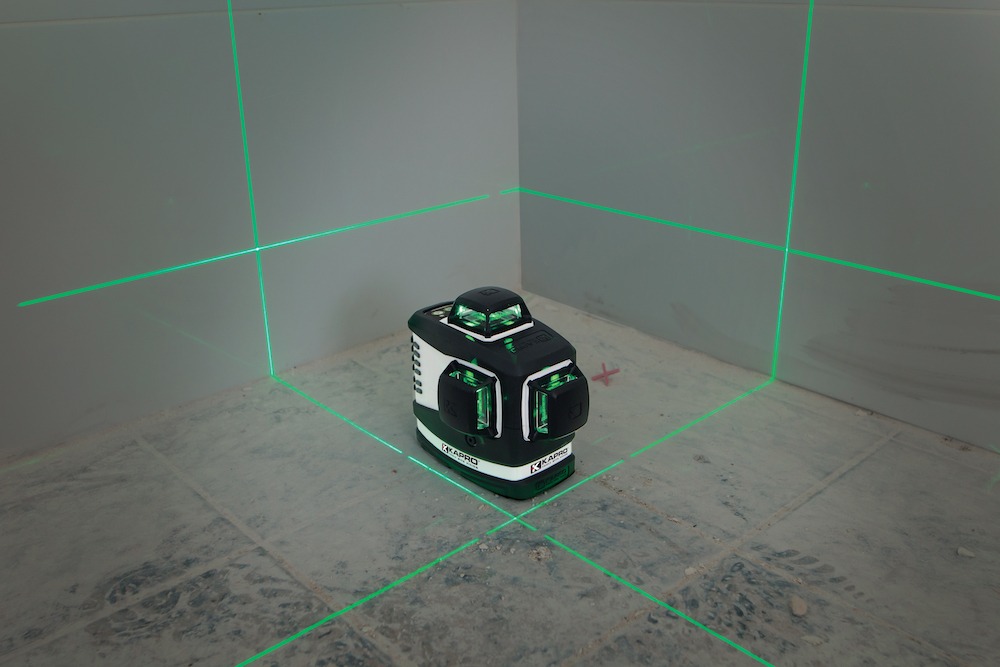

883NG PROLASER® 3D Three-line Laser - 360° Beams

The 883NG is designed for layout and leveling applications. It projects three 360° laser lines that can cover an entire room or jobsite layout.

Highlights:

- Green laser for increased visibility.

- IP65-rated water and dustproof.

- Pulse mode for use with a detector up to 200ft.

- Three-year warranty

Find out more about the 883NG on www.shopkapro.com.

8991G PROLASER® Electrota™ Self leveling Rotary Laser Level

The 8991G is designed for long-range extra accurate leveling applications. It is a horizontal 360° laser line over an area up to 1,960 ft in diameter and its unique side-thread lets you turn it use it also for vertical marking.

Highlights:

- 1/8 in @ 100 ft.

- IP65-rated to work in wet and dusty conditions.

- Sloping mode on X and Y planes up to + 5°

Find out more about the 8991G on www.shopkapro.com.

Stabila

Stabila has incorporated laser technology into their line of levels since 1994. They feature three laser level types: point lasers, line lasers, and rotation lasers.

LAR 160 G rotation laser is a high-performance receiver covering an expansive working area of up to 2,000 ft in diameter. It has a leveling accuracy of 1/8 in @ 100 ft.

- Features green laser beams for improved visibility indoors.

- Durable design that is waterproof and dustproof.

You can learn more about the LAR 160 capabilities and features at www.stabila.com.

LD 250BT 165 Bluetooth® Laser Distance Measurer

The LD 250BT measures up to 165 feet. It handles many measurements that can easily be transferred to a tablet or smartphone using Bluetooth® Smart 4.0 technology.

- Good for indoor use

- Compact design

- IP 54 class – protected against dust and water

- Two-year warranty

Find out more information about the LD 250BT distance measurer at www.stabila.com.

What’s the Bottom Line?

When laser technology is incorporated into the construction process, it can improve the efficiency of jobs. Masons benefit from laser technology as it brings added precision and accuracy to the work they do. Advances in technology improve efficiency, which can lower labor costs. Plus, it can identify job challenges early on. This helps a mason better serve their clients while keeping excess costs from overruns and mistakes to a minimum.