The Fechino Files: Flood Rebuild

Words: Steven Fechino

Steven Fechino

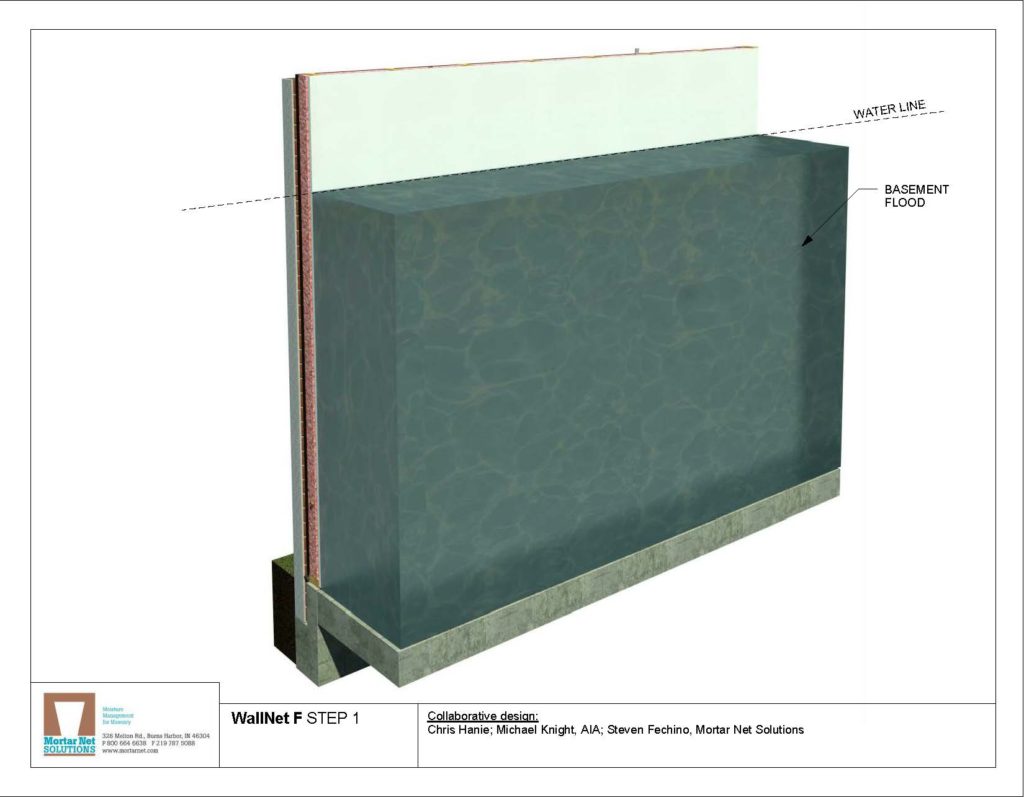

The idea to rebuild after a flood from the inside is not original, however, the outline I will present is designed to save the owner of a flood repair project both time and expense. This design was a joint effort between Mortar Net Solutions, Michael Knight, AIA; friends at Gensler Architecture, and Chris Haine.

Once we were confident that this installation would create a manageable air space to allow air and water to move behind the veneer, the plan moved forward. Mortar Net Solutions developed a ten-step plan, instructions for which are available as a free download for anyone who can benefit from this option, https://mortarnet.com/wallnet-f/wallnet-f-demolition-installation-instructions.

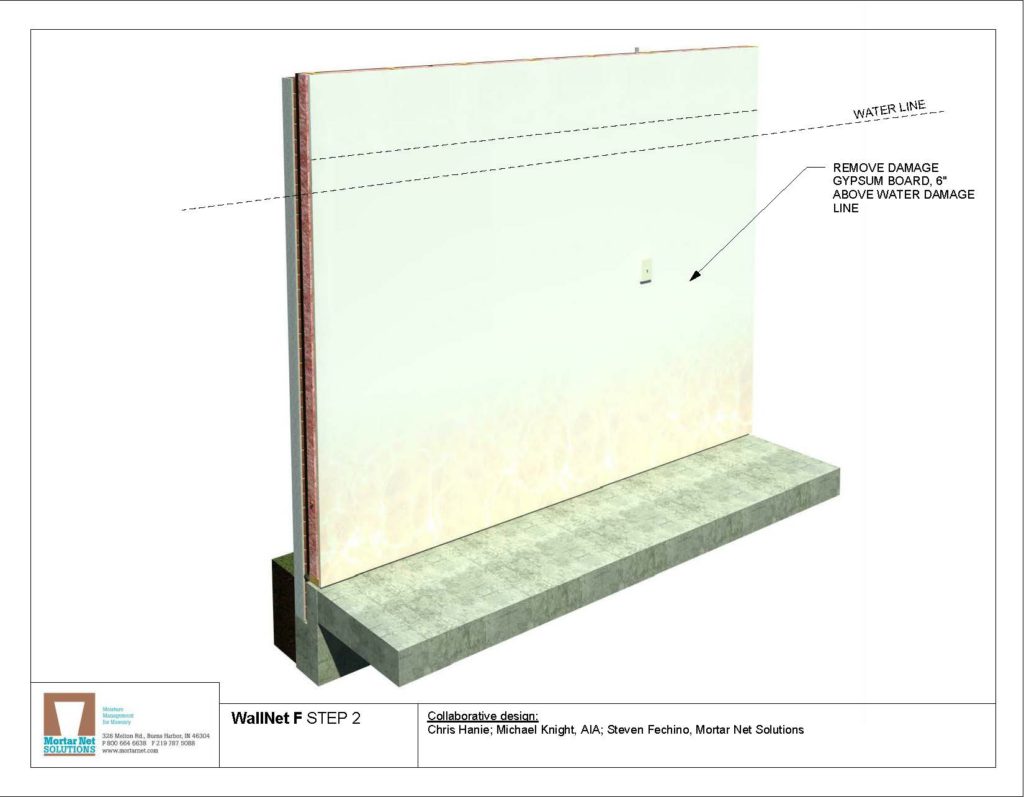

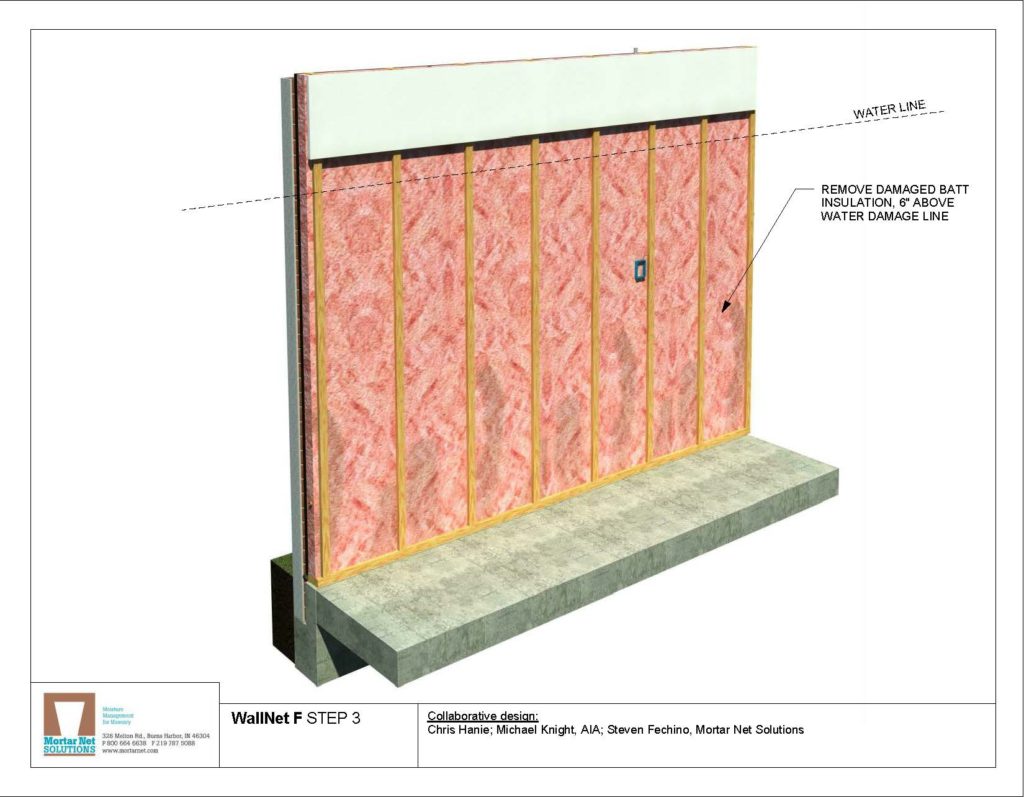

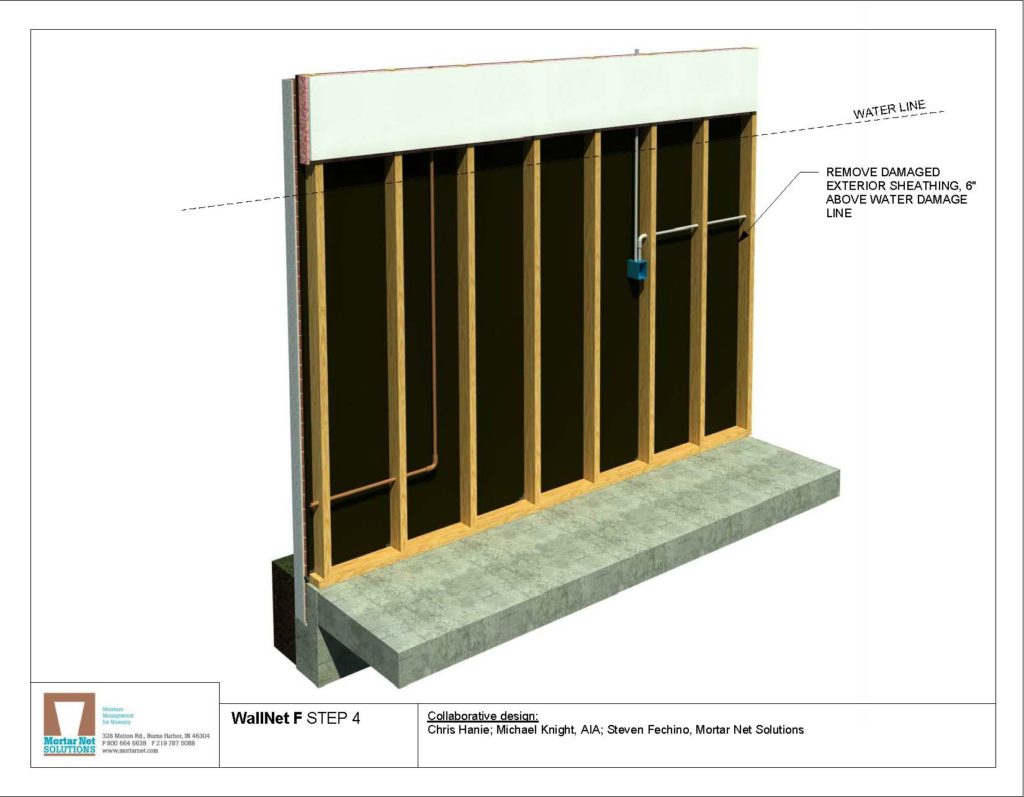

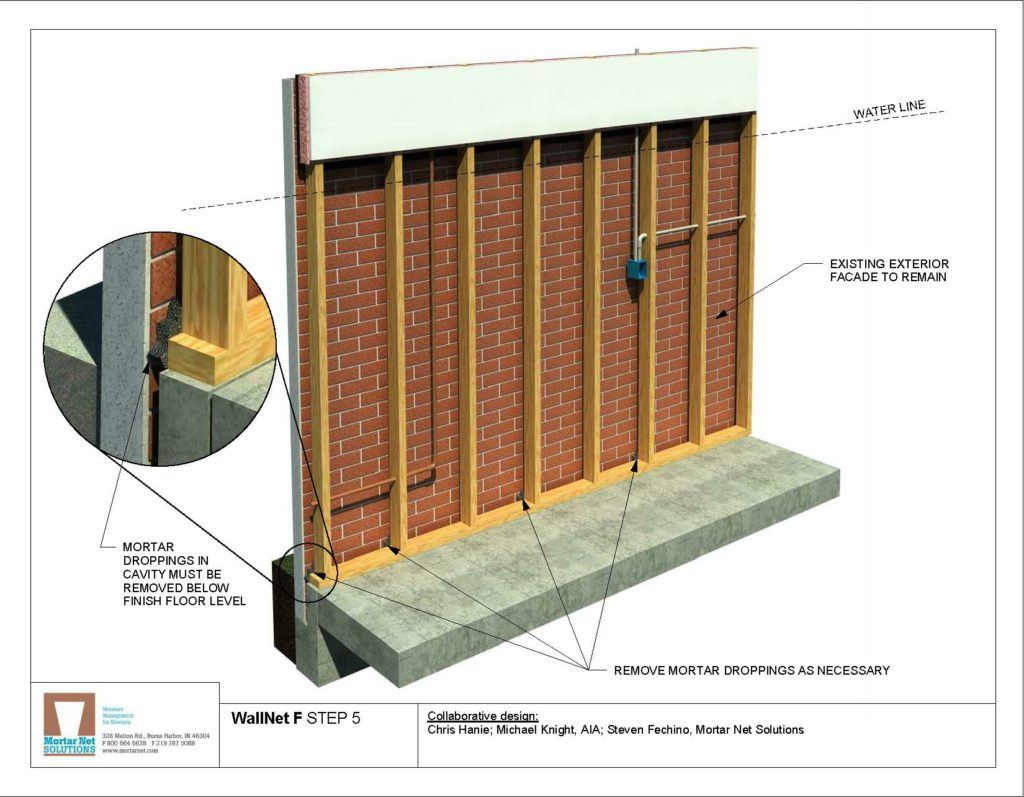

Since materials found in the existing structure are typically and completely saturated, they needed to be removed, including the interior drywall, polyethylene plastic, batt insulation, and exterior sheathing. Images 3 and 4 here Removing the materials from the inside was challenging. However, the existing brick façade could remain, and the house could be locked at the end of each workday to secure tools and personal belongings.

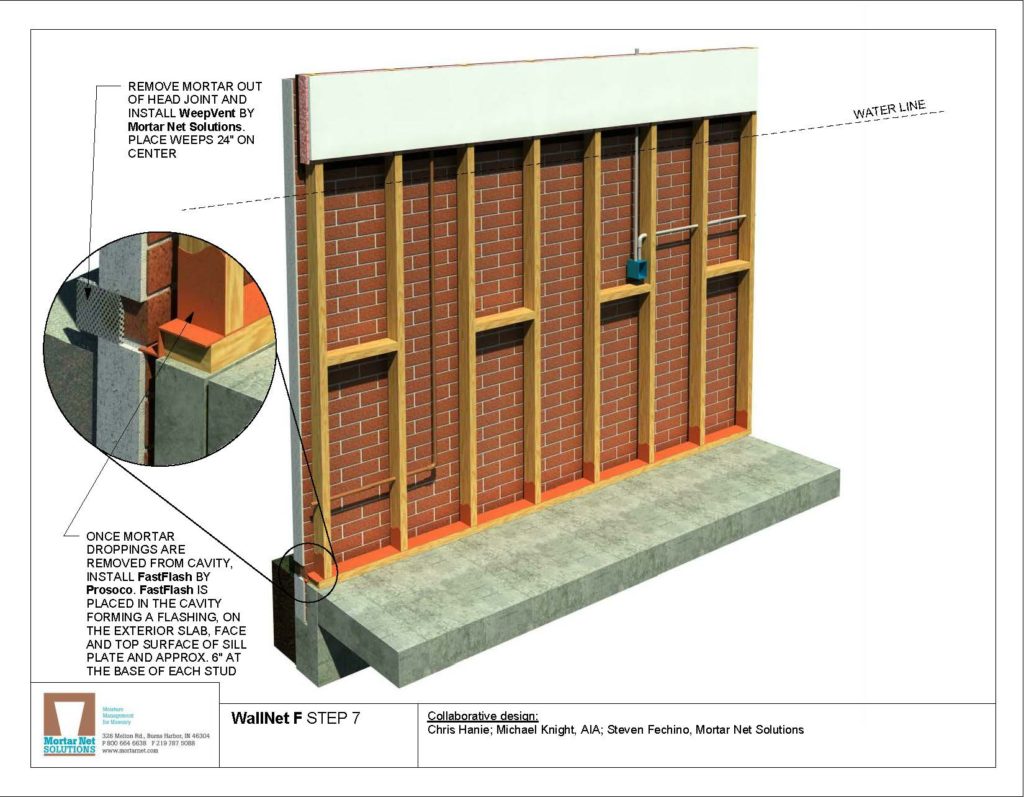

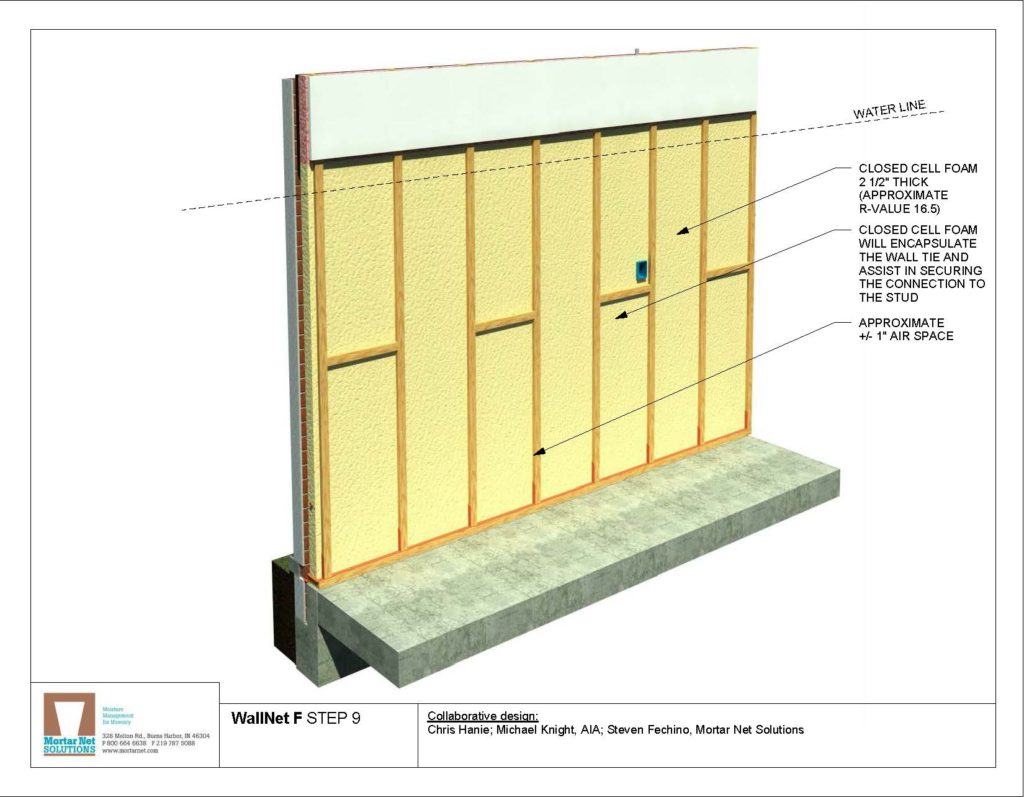

The brick ties remained but were loose at the stud. This connection between the tie and the stud will be tightened when the closed-cell foam is installed as detailed in the drawing. Once the interior envelope materials were removed, the final step in debris removal was to remove the mortar droppings from the base of the wall. This time-consuming task was important to the success of the design. The droppings were removed, so a flexible flashing and weeps could be installed at the base of the wall. This completed the proper weeping of the cavity.

Installing flashing in such a small cavity with the existing wood studs is possible using a Prosoco product, FastFlash. This gunnable material can be troweled into the base of the cavity from the inside to form a flexible flashing. WeepVents™ was installed in the head joints directly at the FastFlash level to prevent any accumulation of liquid in the cavity.

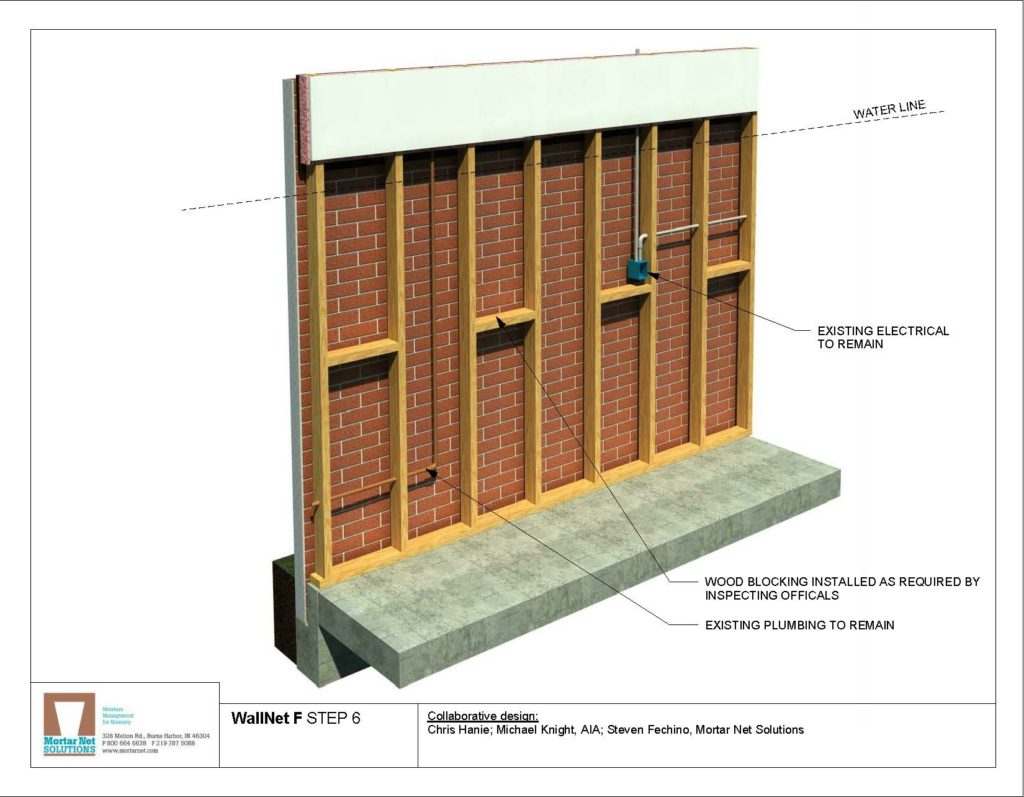

Local codes may require additional blocking to the stud wall. Stability of the wall with the use of commercial, closed-cell foam to a thickness of 2.5 inches offered the same properties as ½-inch sheathing board. This information is important for the inspector to know when deciding on additional bracing. At this point, inspections of all water, electrical, communication, and vacuum lines found within the walls should be performed.

Before the final steps take place, many building owners will need to obtain a certification showing that the studs and framing members are dry and mold-free from a certified testing company. Typically, in flooding situations, drying times could extend two to three months of continuous fan and dehumidifier operation.

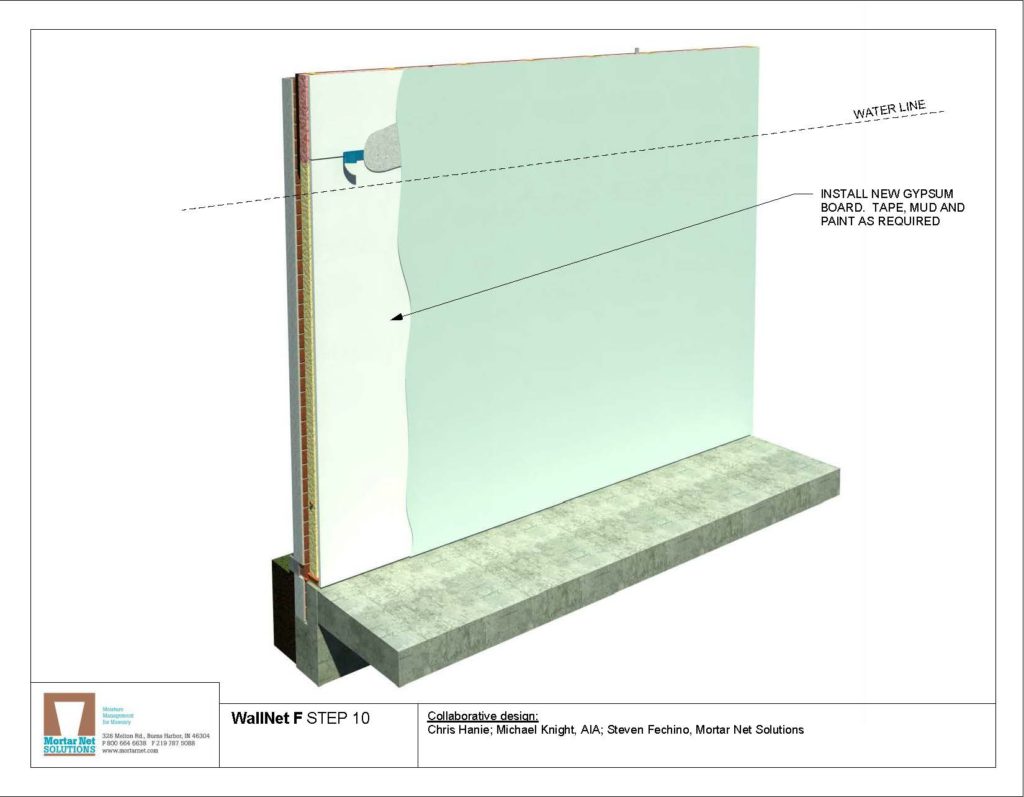

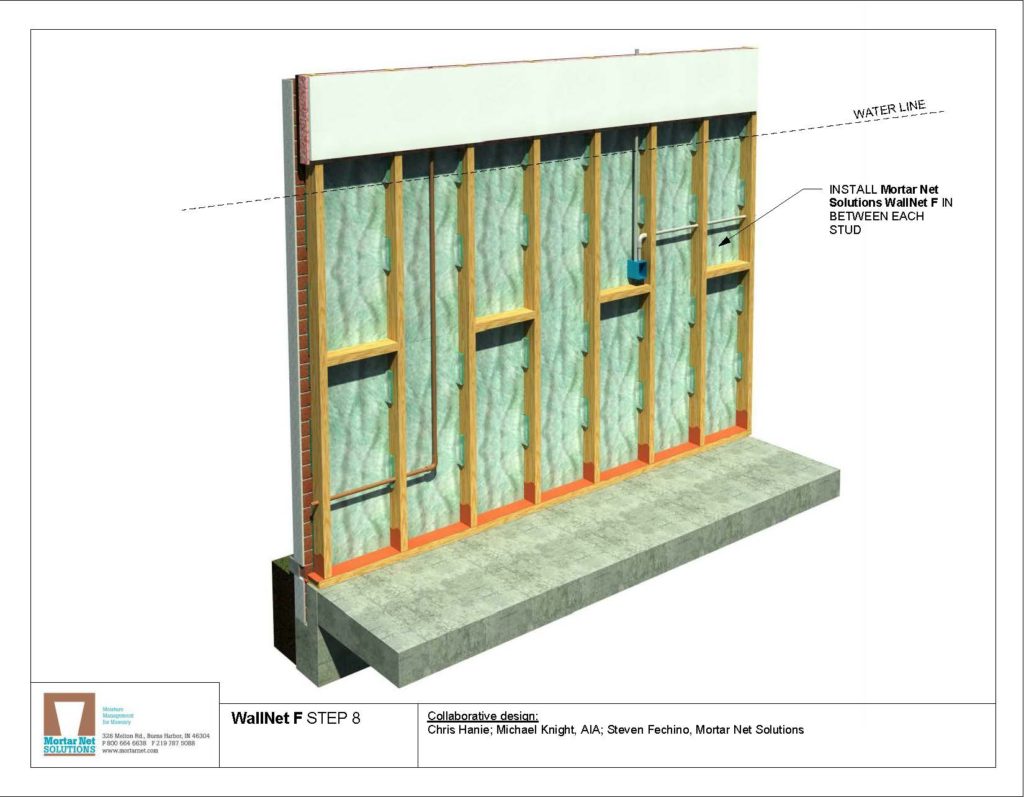

Now, the build back is ready to begin. Mortar Net Solutions WallNet F is tested, proven, and designed for this repair. It is pre-cut material that would fit and attach easily between the studs and around the existing brick ties. The ties needed to be inside of the mesh for the closed-cell foam to fill the gap between the tie and the stud, re-establishing a secure connection of the tie to the substrate. With all of the mesh in place, the installation of the closed-cell could begin. With the closed-cell foam completed, the final steps in installing the drywall, tape and joint compound, primer, and paint could be completed.

This repair, based on the local comparison, was about one-fifth of the expense of removing and replacing the wall from the outside when the brick was removed. Building owners do not have to rebrick, landscape, or secure tools and personal belongings away from the site during construction. Building owners do not have to worry about additional rainstorms saturating the exposed framing.