Maintaining Your Level

Words: Joanne Anderson

Words: Joanne M. Anderson

Photos: Keson-SOLA, Kapro Tools, rootstocks

The humble level in the mason’s toolbox sets the stage for the finished project, whether it’s a 4 x 6-foot patio, 5-story brick commercial building, retaining wall, new house, or sprawling school. A level foundation provides the base from which everything else can be constructed in the quality standards, which demand true vertical walls and square corners. Credit gravity with making it possible to determine what is horizontally level from a precise 90-degree angle with a vertical plumb line.

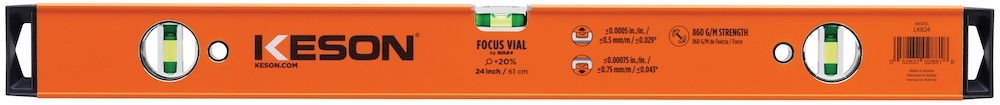

As the bedrock of construction, level surfaces provide stability, comfort, safety, and strength, and level tools are indispensable all along the way. Jude Nosek, marketing director for Keson LLC, recommends investing in a high-quality aluminum box beam level. Keson is a third-generation family business whose vision is: “To be the world’s most trusted source of measuring and marking products.” Keson products are “for people who are passionate about their work and getting it done right. We think this might be just about everyone.”

Gal Wollach, vice president of business development at Kapro Tools, also advocates the box beam level. “People think that I-Beam levels are durable when actually their construction is the weakest vs. shear forces. Box levels are more durable, and cast levels are the only ones that will not bend over time when being tapped.”

Kapro is a leading laser level manufacturer in Lake Mills, Wisc., between Madison and Milwaukee. The small hamlet has around 5,800 residents, according to the last U.S. census. The Kapro Prolaser® levels are marketed as transforming a 2-person project into a job for one and are affordable, easy to operate, and have added value with integrated features, kits, and accessories like storage bags, tripods, and hard cases.

Levels, like many stone mason tools, can last a lifetime with proper maintenance and care. As a precision measuring tool, the level needs to be revered for its function and handled with respect. “Make sure the level surface is clean and unbruised and that the surface you are placing it on is also clean. A grain of sand can cause a 0.01”/1” deviation with a 1” shift per 2.7 yards,” Wollach points out. “It is better to keep your level in ambient conditions – extreme cycles of cold and warm have a long term effect on the attachment of the vial to the profile which consequently affects the accuracy of the vial. Kapro has developed a vial holder made of composite materials that have the same expansion co-efficiency as aluminum which deals with thermal cycles much better than other levels. Temperature affects the size of the bubble in the vial. The colder the surroundings are, the more the liquid shrinks and the bubble expands – this is why we leave 0.04” between the edge of the bubble and the lines.”

Keson, based in Aurora, IL, the state’s second-largest city, is the family name Nosek spelled backward. About two years ago, it merged with the Scheyer family business of SOLA. SOLA was founded in 1949 when the family invented a level tool on the roof of their home in Austria. Together, the family businesses under the Keson LLC banner offer to measure and marking tools designed with precision engineering and industry-leading technology. SOLA-brand levels are found on job sites around the world and across the U.S.

One of the common misconceptions about levels, Nosek explains, is that the top and bottom surfaces of the level are equally accurate. “They are not,” he states. “Levels are calibrated in a vial on top against measuring surface on the bottom. This is the most accurate orientation.” He suggests:

- Use a wet towel to keep levels clean from concrete, mortar, or mud

- Check the accuracy of a level, especially after dropping it

- Replace damaged end caps

- Transport and store levels in a bag, toolbox, or hard case

“If you take proper care of your level, it could outlast you,” says Wollach, who cautions not to place a dirty level in a bag or a clean level in a dirty bag. “If the interior of your bag is dirty, the vial will get scratched over time. Our bags have external straps that let you strap the level to the bag externally until you clean it, and then you can place it back in the bag.” He adds that “rinsing a level is okay. Wipe with a dry cloth and do not clean the vials with alcohol or anything other than water. Also, cleaning the level as soon as possible is key because the more dry the dirt and cement are, the more potential wear could occur when you clean it.”

David Conroy of Stone Age Masonry in southwest Virginia oils his level once a month. “Some manufacturers suggest raw linseed oil,” he states. “After 30 years of masonry, I have been through a bunch of levels. It pays to buy a good one which holds up to the hard life of being a stonemason. I think Stabila makes the most accurate one, but they are too light for my taste. I like a good wood level, and it seems to take the abuse better than others. I've had Crick and Smith levels. I like the way Smith crafts tongue and groove on their levels. They hold up well through all the abuse I have thrown at them. I have banged on my Smith level with a hammer or my trowel and once I used it as a pry bar. I love her; LOL. Masons are hard on everything, so the answer to everyone’s questions on Facebook is Smith is the best level for me.”

Vials in a spirit level, once filled with alcohol for its non-freezing properties, are now ethanol, a much-diluted form of alcohol in a yellowish-green color. There are additives to provide UV protection and maximize performance in a wide range of temperatures. Levels can be submerged in a bucket of water without risk of compromising the totally-sealed vials. Some level owners will add the sulfamic acid cleaner to the water for levels with heavily caked and dried mortar. Use heavy rubber gloves to handle these levels. A level might need to be brushed to remove dirt or mortar in small crevices.

Because of the significance of being level in the construction of most anything, the level itself should be checked often for accuracy, particularly after dropping it. These simple tests are posted at nailgundepot.com.

Check horizontal accuracy:

1. Place the level on a horizontal surface; make a mark on the surface at one end of the level.

2. Take a bubble reading and remember where it is.

3. Turn the level 180 degrees and place the other end of the level at the mark you made earlier.

4. Read the level.

5. If the bubble returns to the same place, the level is accurate; if not, it is not accurate.

6. Repeat again to validate.

Check vertical (or plumb) accuracy:

1. Place the level vertically against a wall; make a mark at one end of the level on the wall.

2. Repeat steps 2 – 6 above, but keep the level vertical instead of horizontal.

One of the best ways to maintain your level is by protecting it with a case. SOLA offers a rugged, 10” belt pouch for its torpedo level and bags with clip-on or off-shoulder straps in 24, 48, and 78 inches. Each of the large ones can hold two levels. Kapro also offers level cases. There are level cases with multiple pockets so you can carry all the levels you may need in a day.

When it comes to replacing a level, Wollach suggests “shifting to a level with an advanced vial. Kapro takes pride in having the most advanced vial based on the Optivision™ Red technology. These vials are up to 8X more visible than traditional vials and are made of polycarbonate, the toughest polymer known to man, and offer the highest accuracy level in the market.” [See https://kapro.com/product/935-optivision-red-torpedo/.]

“In the past,” Wollach continues, “level end caps used to be made of plastic. No more. If you are in the market for a new level, get one with rubberized heavy duty end caps which will keep your level in operation for a longer time.” Furthermore, he suggests adding a digital level like Kapro’s 905D or the 985D-L Digiman® with a laser pointer as well.

The level is imperative to the structural integrity of any masonry project, so caring for the level itself is equally imperative to assure high-quality results with true horizontal and vertical walls and 90-degree cornering. While laser levels are useful in the planning stages, nothing replaces the traditional spirit [bubble] level for accuracy. And accuracy is essential in building construction and masonry work as it is in heart surgery, software programming, and airplane landings.

Joanne M. Anderson is a southwest Virginia freelance writer and frequent contributor to Masonry Magazine. www.jmawriter.com