On The Level: Keson and SOLA: How to Pick a Durable Level

Words: Jude Nosek

Words: Jude Nosek, Keson/SOLA

Levels are essential to every masonry job. No matter how big or small, having an accurate level, and one that stays accurate, is critical. Despite the best effort of everyone involved, construction sites are imperfect places where mistakes happen. Things get dropped, and things fall down. Investing in a durable level that can withstand these accidents is important.

Durable levels are less likely to go out of level or out of plumb when dropped. After each drop or fall, you should check to see that your tool is unharmed and still accurate. By choosing a high-quality level that can take a fall in the first place, you can avoid having to spend time replacing them and, better still, spend less time correcting costly mistakes that an out-of-alignment level might cause.

What Makes a Level Durable?

Durability comes in many forms. Here are some specific durability features to look for when choosing your level:

1. Choose a Box Beam Level For Their Superior Profile.

Why Box Beams?

Levels come in two basic styles: box beam and I-Beam. Box beam levels are stronger and more durable than I-Beam levels. They are more costly because there is more material and because more advanced manufacturing techniques are required to build these superior levels. Even so, not all box beam levels are the same. Just because a level is a box beam, you cannot assume that it is going to provide you with the necessary durability.

A box beam level is basically a hollow aluminum rectangle called a profile, or sometimes a frame, into which the components of a level are affixed. The thickness and structure of that profile contribute to the durability of the level. In level design, a lot of time is spent on the balance between comfortable and usable weight and profile durability. A level could be made of a solid block of steel, which would provide fantastic strength, but might be too difficult to produce and too unwieldly to use for most workers. Aluminum is strong and light. It can also be extruded into consistent, durable profiles for the production of levels.

Why not I-Beams for durability?

By their design and primarily because there is less material, I-Beam levels are inferior in durability to box beam levels. They are not designed for strength, but rather for cost and for production efficiencies. If treated delicately and with care, an I-Beam will be as level as a box beam level at the end of the production line. However, once people get their hands on an I-beam level and subject them to the rigors of the world (transporting to and from the work site, project use, and job sites primarily), I-beams will not fare as well as a more robust box beam level.

What to look for in a box beam?

Generally speaking, a heavier aluminum profile is going to be stronger and more durable than a lighter aluminum profile. The amount (measured grams or ounces) of aluminum over length (measured in meters or feet) will give you the best indication of profile strength, which contributes to overall level durability. Some profiles have additional strength elements built into them, like ribs or ridges that run the length of the level. Other profiles use a modified box shape (like an X, for instance) to provide some structural rigidity.

Box beam levels are more durable than I-beam levels. However, not all box beams are the same. Ask your tool supplier which brands (and which type/model of each brand) get the fewest returns, have the fewest warranty issues, and have the best customer service.

2. A Level Needs Strong Vials Filled with Environmentally Robust Fluid.

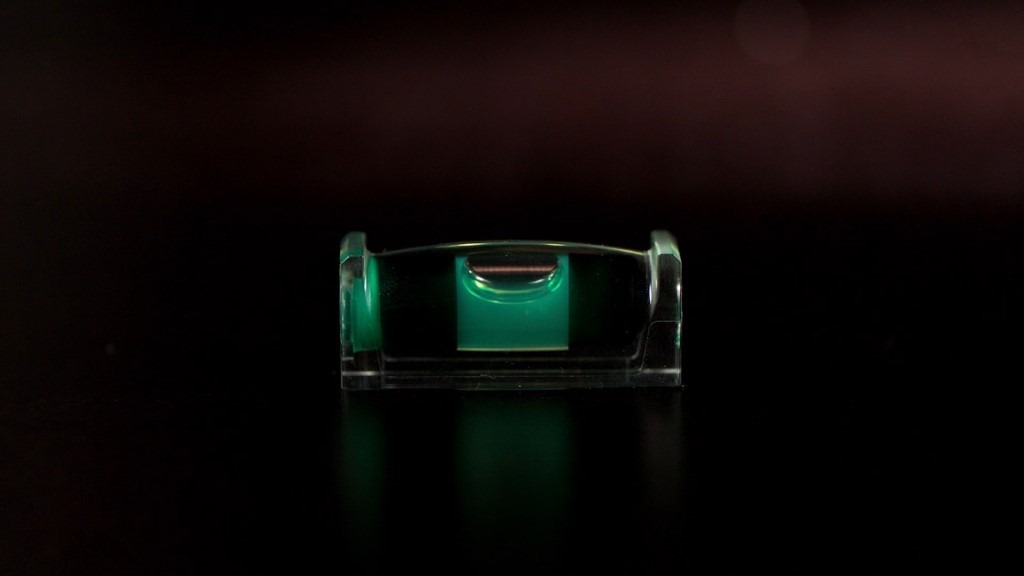

There are a few types of vials available. The strongest type of vial is molded acrylic.

These vials also go a long way toward ensuring a durable product. Besides its resistance to deformation or breakage, acrylic is also highly UV resistant, so sunlight won’t cause the color of the liquid in the vial to fade. SOLA and Keson products feature the FOCUS vial. The FOCUS vial also uses a patented ultrasonic welding of the vial to ensure there is no risk of a leak. Moreover, the fluid make-up of the FOCUS vial is immune to electrostatic interference (not all vials are, with some the bubbles move when in contact with an electromagnetic field) and resistant to temperature changes and breaking up bubbles on impact. This later might not seem like a big issue, but if you are waiting for your vial bubble to reform a few (or few dozen) times a day, it can be irritating.

Keep the Components in Place

You can have a great vial. You can have a great level profile. However, if you stuck that vial to that profile with some chewing gum or tied it into place with some twine, you would not have a durable level. It might be fine for a use or two, but could you trust it for an entire day of level measuring? How about a week’s worth? A vial needs to be set in place above the precision measuring edge of a great profile in such a way that the vial will not come loose or move even the slightest under normal working conditions. For great levels, it hopefully won’t move even under some abnormal ones.

How the vials are held in place varies by level style and by manufacturer, and even by type among a manufacturers’ offerings. It is very often a case of getting what you pay for.

Other components of levels need to be considered as well. You don’t want the magnets that were once flush with the measuring edge to eventually stick out, throwing off your measurements. Handholds and endcaps can come loose over time. All of these components should be held securely in place.

Protected Ends

When a level falls, it will rarely strike the ground completely flat on one side. It’s much more likely for one end to strike the ground first, taking the brunt of the fall. Think about flipping a coin. It would be very rare for a coin to fall so that heads or tails side fell flat against the ground. The edge of the coin is more likely strike first. The same is true for a falling level. It’s possible for one of the flat sides of the level to fall against the floor, but it’s much more likely that one end or the other will strike the ground first. This offers an opportunity to cushion the impact.

A level with cushioned end caps will absorb the shock of the impact. This can help ensure that the tool stays accurate. A level is a precision measuring tool. The vials are affixed and aligned to the measuring edge of the product. These vials are held in place by some means (often glue, screws, physical tension, among other techniques). Any impact has the potential to jar or disrupt the alignment of that vial. The softer or more deadened the impact, the more likely the vial will remain stable.

A high-quality level has end caps. The highest quality often have end caps that are made out of more than one material. They are designed with impact as an inevitable occurrence—it’s not a matter of if a level is going to strike the ground unintentionally, but rather, when. So, keep your end caps on. Removing them often leads to losing them or to damaging them, and this will impact your level’s durability.

Pinpoint Accuracy

No matter how durable your level is, if it isn’t accurate to begin with, then it’s still not going to be practical. Accuracy in levels often falls in a range of spectrums, meaning that there may be some variation in the accuracy over a specific length.

SOLA Box beam levels are accurate to within .3mm per 1 meter in standard position, which means it delivers accurate results every time. Making sure that the level you choose is both highly precise and highly durable will ensure that you won’t need to replace it any time soon.

But in the event your level is dropped, hit, crushed or otherwise jarred, make sure to check it for accuracy before you use it again. After all, sometimes a level’s damage is immediately noticeable, either through a cracked case or some other visual defect, but sometimes the level may be slightly out of plumb with no visual indication.

If your level has been dropped or damaged, follow these steps to confirm its accuracy has not been affected before you continue to use the level on your job site.

Choose a Better Level

A durable, comfortable, easy to use and accurate level can help eliminate a lot of issues on the job site. Professional levels with unbreakable, magnified and fog-proof acrylic vials that have been reinforced for better durability, such as SOLA levels with FOCUS vials will ensure better results on every job.

Invest in a good quality, aluminum alloy level with reinforced, cushioned ends to ensure durability, and take care to protect this important tool from the common hazards of the job site to ensure a long life.

In 2018, the Nosek and Scheyer families joined together to form a new company – Keson LLC. Keson and SOLA are both family-owned, third generation companies currently led by the grandsons of the company founders. Keson started in 1968 in the basement of the Nosek family home in Berwyn, Illinois. SOLA started in 1949 with a leveling tool invented on the roof of the Scheyer family home in Goetzis, Austria. Both companies are leaders in measuring and marking tools, offer complementary product lines, and share very similar values. With a combined 120 years of market experience, Keson LLC builds upon Keson’s U.S. manufacturing, existing distribution network and strong relationships by adding SOLA’s European manufacturing expertise, precision engineering and industry-leading technology.

Keson is headquartered in Aurora, Illinois, and is well known in North America for providing reliable, innovative, and easy-to-use measuring and marking products to professional tradespeople who are passionate about their work. SOLA is headquartered in a state-of-the-art manufacturing facility in the shadow of the Austrian Alps and is a market leader in spirit and screeding levels in 30 countries around the world. Now united, and operating from Aurora, Keson LLC will provide the outstanding products and service that will continue us to earn and keep the trust of tradespeople and of those who supply them with the tools they need.