Anchors, Connectors, and Fasteners: Remedial Wall Ties

It happens occasionally on a job site, veneer ties inadvertently get left out of the wall during construction or some of the wall ties are fastened to the exterior sheathing and not the wood or metal studs as building code requires. Occasionally we run across existing projects where missing or damaged ties are causing a problem such as bowing of the veneer or there is poor connectivity between wythes in older multi-wythe masonry. Rather than taking down a veneer and reinstalling it or rebuilding a multi-wythe masonry wall, there are readily available solutions from a number of manufacturers.

Installation of helical ties in a stone veneer. The pilot hole is being drilled in the upper bed jointand a helical tie is being installed in the lower mortar joint.

Helical Ties

Helical ties are frequently used to re-anchor veneers or to augment the tie system in multi-wythe walls. This type of tie is formed from stainless steel straps that are twisted to make a self-tapping tie. A pilot hole is first drilled through a mortar joint in the veneer and into the backup or, in multi-wythe masonry walls, the pilot hole is drilled through the poorly bonded wythe and into one or more of the adjacent wythes. The tie is then driven in, using a hammer drill and a product specific driver that will slightly recess the tie below the surface. The resulting small hole is then pointed over with matching mortar, making the repair nearly invisible. The advantage of this type of remedial anchor is that they are quick to install and are relatively inexpensive. However, if the backup is stud construction, determining the stud layout can be time consuming. Locating the studs is necessary as building codes require that the helical ties, used to anchor a veneer, penetrate the wood or steel studs of the backup. Pullout tests can be done on the ties to derive allowable design loads or verify that design values are being achieved. Commonly available helical ties are made by Helifix (DryFix), Simson Strong-Tie (Heli-Tie), Hohmann & Barnard (Spira-Lok), Powers (Heli-Pin) and others.

Cutaway view of a remedial expansion anchor for veneer and wood stud backup (image courtesy of Hohmann & Barnard).

Expansion Ties

In some cases, veneer anchors may be required to develop higher loads and single or dual expansion ties are typically used. Single expansion ties are intended for stud backup systems and consist of either a lag screw for wood studs or a self-tapping metal screw for steel studs that are attached to a threaded expansion anchor that expands within the veneer. A pilot hole is first drilled through a mortar joint in the veneer. Once the tie has been driven into the stud, the outer plug is expanded by a special driver securing the expansion anchor within the veneer.

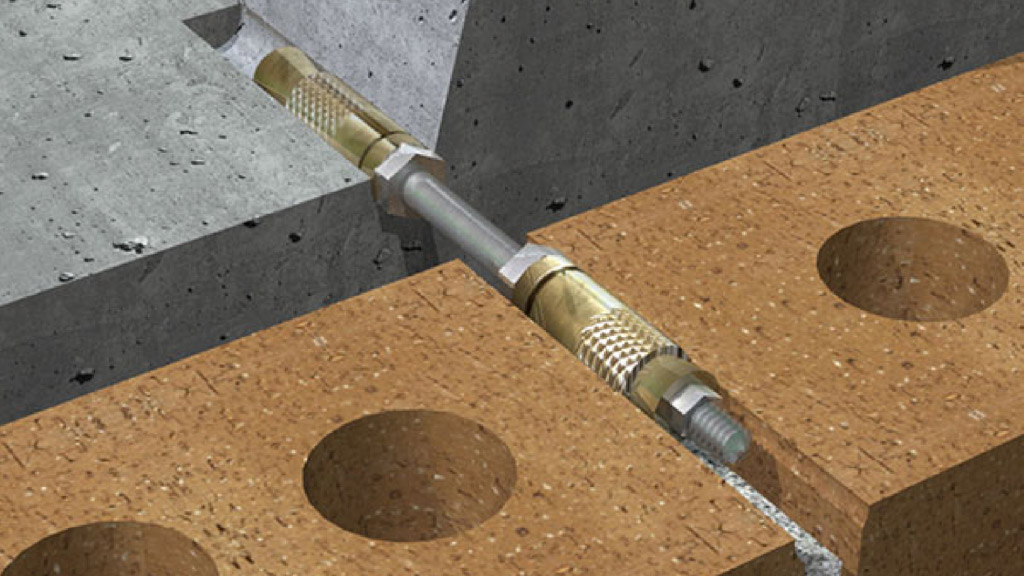

Cutaway view of a remedial expansion anchor for veneer over CMU or concrete backup (image courtesy of Hohmann & Barnard).

Double expansion anchors are intended for use with concrete, CMU or clay tile backup and have two expansion anchors on the same threaded shaft. A pilot hole is drilled through a mortar joint and into the backup for a specified depth. Installation tools are used to first expand the expansion anchor within the backup and then expand the anchor within the veneer. Both anchors are torqued to a specified value to achieve the design load capacity. In some instances, pull testing may be required to establish the design load capacity. Expansion type anchors are made by Helifix (TorkFix), CTP (Grip-Tie), Hohmann & Barnard (Torq-Lok) and others.

So, while remedial ties aren’t commonly used in typical masonry construction, they have their place whenever veneer ties are inadvertently left out, improperly installed, damaged or corroded. Similarly with older multi-wythe masonry, remedial ties can supplement the lack of headers or provide additional bond where diagonal (hidden) headers are used.