Preliminary fatal injury rate calculations confirm that mobile elevating work platforms (MEWPs, also known as aerial work platforms or AWPs) are one of the safest ways to perform temporary work at height. This latest analysis complements IPAF’s release of the 2014 MEWP-related accident data and indicates that although the total MEWP rental fleet has increased in size, the fatal injury rate has fallen.

- The MEWP fatal injury rate as calculated by IPAF takes into account the following factors:

Estimated rental fleet size, based on the IPAF Powered Access Rental Market Reports

Estimated average utilization rates per country and worldwide (utilization rate is defined as the share of the fleet out on rent at any time over a year)

Average days worked per year (5 days a week for 50 weeks a year)

The number of fatalities involving MEWPs in a given year, based on the IPAF accident reporting project

Presenting the research, Chris Wraith, IPAF technical & safety executive, noted that IPAF is calculating the fatal injury rate based on the number of MEWP fatalities worldwide against the MEWP rental fleet worldwide and their estimated utilization rate only, as no accurate data is currently available to include the total number of end-user owned machines and their utilization rate. He said, “Comparing fatalities across the whole industry with the total fleet size will most probably bring down the fatal injury rate, so IPAF is currently taking a more conservative approach to the question, ‘How safe are MEWPs?’ and this is an initial attempt to measure and quantify MEWP safety.”

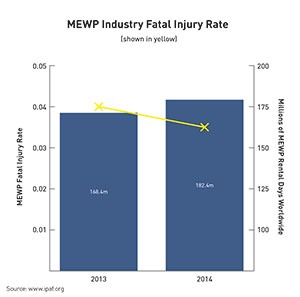

Based on the estimated rental fleet size, the average utilization rate and the average days worked per year, the number of days a rented machine was operated per year was estimated at 168.4 million worldwide for 2013. Taken with the 68 reported MEWP fatalities worldwide in 2013, the fatal injury rate (i.e. the number of fatalities per 100,000 days a rented machine was operated) was estimated at 0.040. For 2014, the number of days a rented machine was operated per year was 182.4 million and the number of reported MEWP fatalities was 64, to give a fatal injury rate of 0.035.

[caption id="attachment_11008" align="alignright" width="300"] Shown is an illustration of the MEWP fatal injury rate in relation to the millions of MEWP rental days worldwide.[/caption]

The MEWP fatal injury rate was put into perspective with other existing data on accidents and fatalities worldwide. Information published by official bodies based on accidents as a proportion of workforce was found for France, Singapore, the UK and the US concerning the number of fatalities due to falls from height per 100,000 workers and the number of fatalities at work per 100,000 workers.

The comparison with fatal injury rates due to falls from height and fatalities at work showed MEWPs to be a safe way to work at height. In the US for example, the MEWP fatal injury rate per 100,000 of the workforce in 2013 (the most recent year for which data is available) was 0.03, whereas the fatal injury rate per 100,000 of the workforce due to falls from height was 0.4 (the number of fatalities due to falls from height involving MEWPs was excluded from this figure) and the fatal injury rate per 100,000 of the workforce due to fatalities of any kind at work was 3.27 (the number of fatalities involving MEWPs was excluded from this figure).

The MEWP fatal injury rate was reviewed against other relevant industry sectors. However, the research found little commonality between industries in the way that fatalities are reported or tracked. All calculations and comparisons have been checked and validated by Ducker Worldwide, a primary research-led industrial market research and consulting company specializing in construction equipment and materials.

IPAF’s accident reporting project, launched in 2012, is gradually creating a comprehensive record of known accidents. Newly released figures reveal that there were 64 MEWP-related fatalities in 2014. IPAF’s Rental Market Reports estimate the worldwide MEWP rental fleet at more than 1.1 million (www.ipaf.org/reports).

The 2014 accident figures indicate a small decrease from that for 2013, which have been re-adjusted upwards in the light of new information to show 68 MEWP-related fatalities in 2013. This gives a fatal injury rate of 0.035 in 2014 compared to 0.040 in 2013. Analysis of the 2014 data reveals that falls from height and overturn remain the two main causes of fatal accidents.

The accident data gathered enables IPAF to improve the content of training programs, to develop technical guidance, to target specific high-risk professions or activities, and to provide research findings used to influence standards.

All manufacturers, rental companies, contractors and users are encouraged to report any known accidents (not just fatal and serious accidents) involving MEWPs and MCWPs (mast climbing work platforms) worldwide at www.ipaf.org/accident. This information is used to make the powered access industry even safer than it is today.

For more information, visit www.ipaf.org. Shown is an illustration of the MEWP fatal injury rate in relation to the millions of MEWP rental days worldwide.[/caption]

The MEWP fatal injury rate was put into perspective with other existing data on accidents and fatalities worldwide. Information published by official bodies based on accidents as a proportion of workforce was found for France, Singapore, the UK and the US concerning the number of fatalities due to falls from height per 100,000 workers and the number of fatalities at work per 100,000 workers.

The comparison with fatal injury rates due to falls from height and fatalities at work showed MEWPs to be a safe way to work at height. In the US for example, the MEWP fatal injury rate per 100,000 of the workforce in 2013 (the most recent year for which data is available) was 0.03, whereas the fatal injury rate per 100,000 of the workforce due to falls from height was 0.4 (the number of fatalities due to falls from height involving MEWPs was excluded from this figure) and the fatal injury rate per 100,000 of the workforce due to fatalities of any kind at work was 3.27 (the number of fatalities involving MEWPs was excluded from this figure).

The MEWP fatal injury rate was reviewed against other relevant industry sectors. However, the research found little commonality between industries in the way that fatalities are reported or tracked. All calculations and comparisons have been checked and validated by Ducker Worldwide, a primary research-led industrial market research and consulting company specializing in construction equipment and materials.

IPAF’s accident reporting project, launched in 2012, is gradually creating a comprehensive record of known accidents. Newly released figures reveal that there were 64 MEWP-related fatalities in 2014. IPAF’s Rental Market Reports estimate the worldwide MEWP rental fleet at more than 1.1 million (www.ipaf.org/reports).

The 2014 accident figures indicate a small decrease from that for 2013, which have been re-adjusted upwards in the light of new information to show 68 MEWP-related fatalities in 2013. This gives a fatal injury rate of 0.035 in 2014 compared to 0.040 in 2013. Analysis of the 2014 data reveals that falls from height and overturn remain the two main causes of fatal accidents.

The accident data gathered enables IPAF to improve the content of training programs, to develop technical guidance, to target specific high-risk professions or activities, and to provide research findings used to influence standards.

All manufacturers, rental companies, contractors and users are encouraged to report any known accidents (not just fatal and serious accidents) involving MEWPs and MCWPs (mast climbing work platforms) worldwide at www.ipaf.org/accident. This information is used to make the powered access industry even safer than it is today.

For more information, visit www.ipaf.org. |