Rising to the Challenge

Words: Dan Kamys

REHAB & RESTORATION

CASE STUDY: Mortar

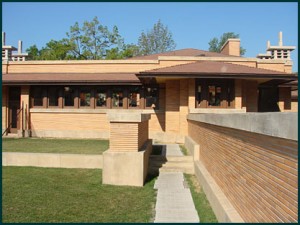

The QUIKRETE Companies were called upon to match 100-year-old mortar applied to a historic Frank Lloyd Wright-designed home.

By K.K. Snyder

As the third stage of a $23 million restoration of the Darwin D. Martin House complex in Buffalo, N.Y., approached, The QUIKRETE Companies were called upon to match new mortar for the project with the historic mortar that had been applied more than 100 years ago — a considerable challenge.

As the third stage of a $23 million restoration of the Darwin D. Martin House complex in Buffalo, N.Y., approached, The QUIKRETE Companies were called upon to match new mortar for the project with the historic mortar that had been applied more than 100 years ago — a considerable challenge.

The overall project focuses on rebuilding masonry walls, restoring face brick and matching mortar for the interior "backup" brick on the 10,000-square-foot main house — Martin House — and a 100-foot covered pergola connecting the house to an interior garden in the complex's glass-roofed conservatory.

"The QUIKRETE Companies have responded to multiple requests for helping to match existing mortar on projects nationwide," says Chris Darner, bulk mortar/construction product sales manager for The QUIKRETE Companies. "As it relates to the restoration of mortar, this project was truly unique in its magnitude, especially given the significance of the home's designer and builder, Frank Lloyd Wright."

Darner says that during the original build between 1903 and 1905, aggregate and masonry sand were obtained from sources that were close and economical. There was little, if any, concern as to the effect the aggregate had on quality. Cement and lime also were found from a source that was readily available. Mix designs were contractor specific, so what worked for one mason may not have worked for another.

Over the years, building owners/developers, architects, general contractors and masons have been educated about the importance of quality and consistency regarding mortar. The QUIKRETE Companies have been instrumental in this effort through leadership and support of organizations, such as the Masonry Contractors Association of America, who focus on promoting industry education, training, codes and standards composition.

Fortunately, ASTM specifications have been adopted and changed based on changes in the industry. In addition, pre-blended materials on construction sites have become specified, rather than an alternative.

So, the main challenge came in unlocking the mortar formula that exactly matched the historic mortar in texture, grit and color gradation, as well as preserved the home's historical accuracy and aesthetic beauty. Working with King Brothers Masonry Contractors and consultants from the Martin House Restoration Corp., QUIKRETE matched the formula, using the resulting local source of aggregate, with the masonry mortar on the historic home.

"The matching of mortar on a building that is more than 100 years old presents many challenges," Darner says. "At the time of initial construction of the multi-structure complex, there were no ASTM specifications or testing agencies to oversee the quality of the materials utilized."

So, inquiries were made to multiple contractors to determine the masonry practices used during the time of construction. Luckily, masonry contractors tend to pass the business along to their families, affording QUIKRETE some insight into past practices, he says.

"We also contacted aggregate and cement suppliers in an effort to identify the source of the materials utilized," Darner adds. "The entire process was an investigation without any documented evidence."

Samples of various cement, lime, pigment and aggregate also were obtained and blended to achieve an exact match, and multiple samples were produced in an effort to duplicate the existing mortar on the Darwin Martin House complex.

Once QUIKRETE was able to achieve an exact match, a sample panel was constructed for review and acceptance by all parties involved with the project. More than 60 different test panels were required throughout this evaluation process.

Due to their support of the restoration and material matching effort on the Darwin D. Martin House complex, The QUIKRETE Companies have received an increase in requests to match existing and historical mortars. In addition, the Bulk Products division of The QUIKRETE Companies continues to expand the product lines they can offer their customer base in the construction industry.

CASE STUDIES:

— Color Blending Masonry: Henry Medical Center Facility Expansion

— Flashing: TotalFlash in Action

— Mast Climbers: A New Nashville Skyline

— Mast Climbers: Keeping the Faith

Side Story:

Return to Table of Contents