Side Story: Case Study: Into the Sky

Words: Dan Kamys

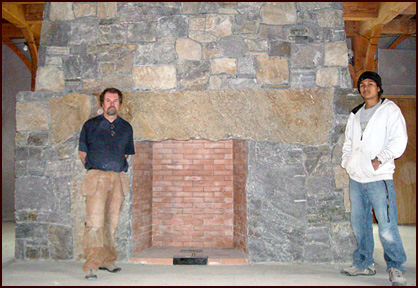

[caption id="attachment_9137" align="alignnone" width="418"] Averaging 13 square feet per day, a crew of three spent more than two months on the first floor. Due to all of the scaffolding up around the work, they were never able to view the entire project until they took it all away.[/caption]

Averaging 13 square feet per day, a crew of three spent more than two months on the first floor. Due to all of the scaffolding up around the work, they were never able to view the entire project until they took it all away.[/caption]

In 2007, Stephen Bushway, owner of Deer Hill Masonry in Cummington, Mass., was contacted by Geary Builders of Cheshire, Mass., to design two stone fireplaces for a timber frame addition in Williamstown, Mass. Owner Jim Geary has a reputation for high-end projects in North County, and this one was no exception.

Architect Morris Schope of Vincent P. Guntlow Associates in Williamstown designed the ballroom addition with a 12-foot-wide fireplace centered in the room, seven feet in from the far end. The 11-foot ceiling was graced with four massive, octagonal Douglass Fir posts, recycled from a closed quarry in Quincy, Mass. Several rendering sketches were done, and Bushway soon realized that the large mass and space required an equally massive look for the stonework. American Granite from Champlain Stone Co. was selected for the project.

The ballroom fireplace face was to be a single lintel stone over post stones and a four-foot-square opening and flush hearth. Bushway went to the Champlain quarry in Warrensburg, N.Y., to select those stones. He was able to find enough split-faced stones for the first-floor fireplace, the wood box floor and stock for the bedroom fireplace on a two-thirds scale, which he later split to width with feathers and wedges.

The challenge

[caption id="attachment_9138" align="alignright" width="225"] The challenge upstairs was to replicate the post and lintel detail on a two-thirds scale. Bushway and his team had to wedge-split the stones to make them proportionate to the stones downstairs.[/caption]

The challenge was to set a 10.5-foot, 1,300-pound lintel stone atop two, 800-pound post stones to create a four-foot-square opening with the same dry-layed look that would characterize the rest of the stonework. Roughing out on the ground using cardboard templates was key. The post stones were set plumb and level against 8-inch cmu backer columns.

The challenge upstairs was to replicate the post and lintel detail on a two-thirds scale. Bushway and his team had to wedge-split the stones to make them proportionate to the stones downstairs.[/caption]

The challenge was to set a 10.5-foot, 1,300-pound lintel stone atop two, 800-pound post stones to create a four-foot-square opening with the same dry-layed look that would characterize the rest of the stonework. Roughing out on the ground using cardboard templates was key. The post stones were set plumb and level against 8-inch cmu backer columns.

The solution

Using a chain fall suspended from a timber spanning the second floor opening and heavy coated cable, Bushway and his team were then able to raise the massive lintel stone to clear the posts and rotate it to find the contact points they had marked outside. Once adjustments were made to find the balance point of the stone and the correct location on the posts, they were then able to begin the repetitious process of lowering the lintel stone onto the posts, finding the contact points, and raising and rotating the stone enough to expose the contact surface for chiseling/grinding away, either on the lintel or post stones, to create a tight, "dry look" fit.

As Bushway gained confidence that the lintel was securely held, he and his team could ignore working inches away from an extremely heavy stone. The chain fall was the perfect tool for raising and lowering the stone without fuss. Having these three stones successfully set created positive site energy for the rest of the project.

On the left side of the mass, Bushway incorporated a built-in wood box. The entire mass stepped back five inches to expose the top of the lintel stone, creating a full-length integral mantle. A gentle side taper of five inches took the work the remaining five feet to the ceiling and helped "ground" the mass.

Return to Table of Contents