Fireplaces & Chimneys: Fireplaces and Chimneys Provide Opportunities for Growth and Profit

Words: Brett Martin

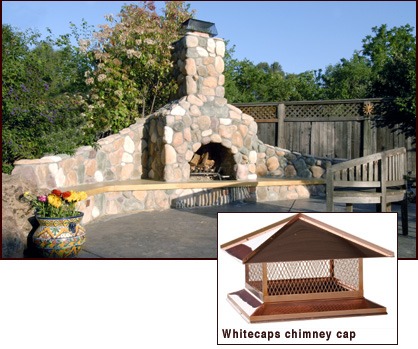

[caption id="attachment_9131" align="aligncenter" width="777"] Image: Morse Remodeling in Davis, CA[/caption]

Image: Morse Remodeling in Davis, CA[/caption]

Nothing complements a home and adds warmth like a fireplace. Surround it with a hand-carved mantel, and it becomes the focal point of a room — a trend becoming more commonplace in luxury homes.

"Most high-end homeowners see fireplaces as a necessity," says Tom Stroud, senior manager of codes and standards for the Hearth, Patio and Barbecue Association (HPBA) in Arlington, Va.

Fireplaces also are getting larger. "What we're seeing is a trend for bigger fireplaces," says Denise Jure, VP and general manager for the family-owned K&W Manufacturing Co. Inc. in Corona, Calif. "Three feet is a standard width, but we're now regularly seeing 60 to 72 inches, and we have made dampers for 10-foot-wide fireplaces."

Outdoors, the popularity of outside living spaces is fueling a demand for outdoor fireplaces. "The big trend is using the patio as sort of an extra room in the home, so we're seeing people using fireplaces in an outdoor setting," Jure says.

More Efficient Fireplaces

Chimney caps and heat circulators make fireplaces more energy efficient. Whitecaps in Monroe, N.C., a manufacturer and distributor, offers more than 2,600 chimney cap options, including stainless steel and copper.

"They are very quick and easy to install," says Gary Chambers, sales and technical director for Whitecaps. "It should take less than an hour to put on the cap. Just put four panels together, sink the tapcons, and put the cap on."

The caps cover the entire chimney opening, not just the flue. "With a chimney cap, you're going to get a better life out of your chimney. It's going to keep rain and critters out. Your investment is going to pay for itself," Chambers says, noting that masonry contractors should install the caps when building the chimneys. "It's seems to be a logical extension of what they're already doing."

K&W Manufacturing offers steel heat circulators that pull in cool air from the room and send fireplace-heated air back out, Jure says. "Heat circulators capture more of the heating energy that would normally go up the chimney." The company also makes steel throat dampers that close off the chimney when it's not in use, keeping heat from escaping and saving homeowners money.

[caption id="attachment_9132" align="aligncenter" width="620"] Image: Morse Remodeling in Davis, CA[/caption]

Helping Masons Profit

What masonry contractors really want to know is whether they can make money in the fireplace business. The simple answer is, "Yes."

Image: Morse Remodeling in Davis, CA[/caption]

Helping Masons Profit

What masonry contractors really want to know is whether they can make money in the fireplace business. The simple answer is, "Yes."

"Building fireplaces is becoming an art form," Jure says. "There are fewer and fewer masons who know how to build a good fireplace. Experienced fireplace masons have jobs booked months and years in advance. This is a good opportunity for new guys who are looking to expand their business."

Jure says throat dampers make chimney building easier. Masonry contractors build the firebox up to a certain point, place the throat damper on top of the masonry, then lay the remaining brick or stone around the damper. "The throat dampers provide a form to help the mason shape the throat," she says. "Our dampers are designed and sized to provide the proper draft and air flow from the firebox into the smoke chamber. It saves the mason a lot of time, because he doesn't have to figure out his own throat dimensions, and he doesn't have to hand lay the masonry to form the throat."

Masonry contractors also can make money installing chimney caps, Chambers says. When building a chimney, the contractors should discuss the caps with the client.

"With something like a hip and ridge cap, it's really a disservice not to at least show it to someone living in a $1 million home," he says, adding that masonry contractors can make a few hundred bucks installing the caps.

[caption id="attachment_9133" align="aligncenter" width="682"] Image: Morse Remodeling in Davis, CA[/caption]

Outdoor Fireplaces

Fireplaces serve as a gathering spot in outdoor spaces, offering light and warmth. HPBA's Stroud says the popularity of outdoor fireplaces in luxury home backyards has a trickle-down effect, prompting homeowners with less-expensive homes to add fireplaces to their outdoor rooms, too. "People want to emulate something they see on tv or in other people's homes," Stroud says. "They want to create their own backyards."

Image: Morse Remodeling in Davis, CA[/caption]

Outdoor Fireplaces

Fireplaces serve as a gathering spot in outdoor spaces, offering light and warmth. HPBA's Stroud says the popularity of outdoor fireplaces in luxury home backyards has a trickle-down effect, prompting homeowners with less-expensive homes to add fireplaces to their outdoor rooms, too. "People want to emulate something they see on tv or in other people's homes," Stroud says. "They want to create their own backyards."

Mark Orme, manager of Southland Brick and Block in Nashville, Tenn., agrees. "Outdoor living spaces are become more popular with outdoor kitchens and fireplaces," he says. Southland Brick and Block offers pre-fabricated fireplaces that are assembled with mortar. "It's quick and easy to put them together," Orme says. "It takes a mason one or two days." He says local masonry contractors work with his company to build outdoor fireplaces. "There are several products on the market similar to ours," Orme says. "Most of the brick and block suppliers have these types of products, so masons should talk to their local supplier."

Some products can simplify building outdoor fireplaces and chimneys. Jure says that although outdoor fireplaces don't need dampers, masonry contractors still use them since they help with the construction. "Throat dampers get used in exterior fireplaces, because masons know that they save work, which saves money," she says.

Setting Detailed Mantels

Masonry contractors are needed to assemble detailed, hand-carved fireplace mantels. Daniel Sinclair, founder and owner of DMS Studios Ltd., in Long Island, N.Y., was trained in Italy and now carves fireplace mantels from quarried marble and limestone.

Setting Detailed Mantels

Masonry contractors are needed to assemble detailed, hand-carved fireplace mantels. Daniel Sinclair, founder and owner of DMS Studios Ltd., in Long Island, N.Y., was trained in Italy and now carves fireplace mantels from quarried marble and limestone.

"A mason for our purposes, installing a mantel, is a stone setter," Sinclair says. "We've made mantels that have more than 70 pieces of stone. That's a very difficult mantel to assemble."

Assembling the mantels is like putting together a three-dimensional puzzle, he says. The pieces have to fit tightly together and have the proper alignment.

"You need a drawing, and you need a numbering system," he says. "You have to number every single piece, know where it goes, and know the sequence when it's installed. This isn't like typical masonry building where you run strings. You use levels. You have to follow the reveals. If you lose them, the pieces won't look right. The mantels are so complex that it can take four to five days — even a couple of weeks — to put them together."

For assembly, masonry contractors need to safely transport the large stone pieces, get them to the jobsite, unload them, and carry them into the room, without damaging the carefully carved pieces. Some pieces are too heavy to be lifted by hand.

Sinclair has carved mantels that cost into the six-figure range, including one for the Lincoln Bedroom in the White House. Masonry contractors who want to get into the mantel-setting business need to learn from an experienced stone setter. "You have to apprentice yourself to a stone setter," Sinclair says.