Setting an Example

Words: Dan Kamys

Brick as a Green Material

The Brick Industry Leads the way with third-party certification in green building design and sustainability

In November 2009, Booz Allen Hamilton’s “U.S. Green Jobs Study” forecasted that LEED-related spending would generate an additional $12.5 billion in GDP between 2009 and 2013. The study also predicts that, in the same period, LEED-related spending will support 230,000 jobs and provide $10.7 billion in labor earnings in the United States. Additionally, the National Association of Home Builders reports that, as of August 2009, more than 4,000 homes are in the certification pipeline for the 2008 National Green Building Standard. Put together, it is clear that the demand for credible documentation that supports product manufacturers’ environmental claims will increase significantly in the years ahead.

Brick industry addresses limitations of self-reported product verification

When compiling documentation to substantiate the green claims of a building product, many architects, builders and designers currently rely on a product manufacturer’s own claims.?? In this scenario, total trust is placed in the manufacturer’s ability to correctly apply the various environmental attributes of its product to a green rating system. With such potential for inconsistency and misinterpretation, the Brick Industry Association (BIA) recognized that architects, builders and designers need a higher level of verification. In April, 2009, BIA approved a policy, developed in conjunction with the National Brick Research Center (NBRC) entitled, “Certifying Brick – an Environmentally Preferable Product Policy.” This policy is the first of its kind in the masonry industry.

BIA enables manufacturers to certify brick as environmentally preferable product with comprehensive, empirically based policy

To meet the highest level of verification, a manufacturer subjects its product’s green claims to the scrutiny of a third-party, impartial and qualified organization.?? Since designers frequently place their trust in such a group to interpret and apply the aspects of being “green” across all of the products it certifies, it is important for a third party organization to have expertise and understanding of the brick industry.?? Given NBRC’s extensive experience with brick, and the fact that it follows the various ethics policies of Clemson University, the NBRC clearly possesses the kind of knowledgeable, third party credibility needed to implement this policy.

The certification program provides clay brick manufacturers a means of verifying “green” claims and focuses on three primary areas:

-

The Amount of Recycled Content. The recycled content of a brick is accurately determined so that the quantities assigned to earn points per the green building rating system are correct. Since materials vary in type and source among brick manufacturers, differences need to be accounted for. For example, recycled material has to be diverted from a landfill and culls from manufacturing must have gone through firing to be considered as recycled material (Figure 1).

-

The Utilization of Renewable Energy. If renewable energy was used in producing the brick, the type and amount of this energy is reported and verified (Figure 2).?? Examples of renewable energy used by brick manufacturers have included methane gas from landfills and sawdust.

-

Reduction in the Amount of Resources Used to Manufacture Brick. If the manufacturer demonstrates a reduction in the amount of resources necessary to manufacture a brick with fewer materials, reduced energy, or both, then the amount of material and/or energy is noted. Points awarded for resource reduction efforts may be available for a limited period, in order to reward those companies that continue to lower the amount of materials and energy used. Reduced resources include actions taken by the manufacturer to produce brick from less material, and/or to use equipment that consumes less energy use in the manufacture of brick (Figure 3).

The National Brick Research Center implements policy with scrupulous third-party review

NBRC developed a rigorous process to verify the environmental claims of brick manufacturers discussed above. The steps that brick manufacturers take to obtain, and maintain, certification are as follows:

NBRC Reviews Brick Manufacturers’ Documentation. The manufacturer submits a request form and background information for each brick or brick blend from a particular plant. The data will be reviewed by the NBRC. The center will then determine if any sampling and testing are required prior to the plant audit. If sampling and testing are required, then the NBRC will obtain those samples and complete the necessary tests.

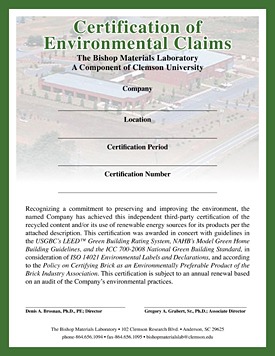

NBRC Conducts an On-Site Plant Audit of the Manufacturing Facility. During the audit, NBRC will verify documentation; discuss recordkeeping requirements and any training required to complete those requirements; inspect locations of recycled and waste materials; and examine the manufacturing process. NBRC then will write a report detailing the materials and manufacturing processes, and proceed with the internal NBRC engineering review. In this segment of the audit, NBRC will confirm that the information obtained does not conflict with the ISO14021 document, the Certifying Brick – an Environmentally Preferable Product Policy, or the green-building rating systems. For certification to be issued, the center’s professional staff must be in agreement. A final report will be submitted to the company for review and, upon acceptance, a certificate and accompanying materials will be provided (Figure 4).

|

|

|

|

Brick Manufacturers Take Steps to Maintain Compliance. To ensure that their certification is valid for a full, three-year period, each site must undergo a yearly re-evaluation of their process and a paperwork review (unless something in the process has changed that warrants a plant audit.) NBRC’s professional staff also will review a manufacturer’s claims as verified by the on-site audit in accordance with the procedures of Clemson University.

By working with the National Brick Research Center, brick manufacturers can obtain a “Certification of Environmental Claims” that validates manufacturers’ claims about a products’ recycled material content, use of renewable energy in manufacturing, and reduced demand on precious resources used in manufacturing.

“This third-party certification program is an integral part of BIA’s overall sustainability and green building design strategy,” says Dick Jennison, president and CEO, BIA. “And, it’s consistent with our mission of furnishing our members the tools they need to position their product as strongly and accurately as possible.”

Return to Table of Content