Side Story: The Style and Durability of Glass Block

Words: Dan KamysMay 2008

Blocks

All photos courtesy of Pittsburgh Corning

All photos courtesy of Pittsburgh Corning

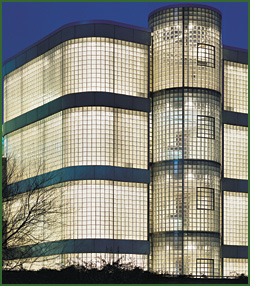

Glass unit masonry, more commonly called "glass block," is being used extensively in homes for windows, showers, partition walls and recreation bars, says Bob DeGusipe, marketing manager for Pittsburgh Corning Corp. in Pittsburgh. The material is also being used commercially in schools, hospitals, office buildings and institutional buildings.

"In commercial applications, the product is ideal where durability with light transmission, privacy and security control are key. Glass block is, essentially, a brick that lets in light." DeGusipe says. "The product can be used with almost any style of architecture. Therefore, it has universal appeal."

DeGusipe is seeing a push toward developing glass block systems that can meet the increasing emphasis on safety and security in buildings, such as hurricane, blast and ballistics protection, while new patterns and colors offer broader aesthetic appeal.

"Finishing blocks to create step-down walls and blocks to turn 45- and 90-degree and tight radius turns offer even more design flexibility," DeGusipe says. "Pittsburgh Corning introduced the new mortar-less ProVantage Installation System in recent years to simplify the installation process."

Clearly green

Glass block is also helping in green building design.

"Since glass block provides excellent light transmission, the product is very suitable for the green movement and helping architects meet LEED accreditation," DeGusipe says.

Glass block is inherently stronger than conventional glass because of the thickness of the faces and the mortar that binds the blocks together, he says. Since the block doesn't have load-bearing capabilities like other masonry block, structural support is needed above block openings.

Glass block is inherently stronger than conventional glass because of the thickness of the faces and the mortar that binds the blocks together, he says. Since the block doesn't have load-bearing capabilities like other masonry block, structural support is needed above block openings.

Masonry contractors don't need specialty tools for installation, says Nicholas Loomis, Pittsburgh Corning senior engineer. Traditional masonry tools and Type S or Type N mortar, mixed stiff, will get the job done.

"The mortar has got to be on the stiffer side, like peanut butter," Loomis says. "You should be able to make a ball all of it. The blocks are not going to absorb the moisture concrete blocks do."