Air Barriers: Impermeable or Permeable?

Words: Dan Kamys

Air Barriers

By Jane Wu

Air infiltration of buildings causes significant heating/cooling energy loss and permits moisture and condensation to collect in the walls. This interstitial condensation creates significant problems for buildings and occupants alike, including poor air quality, mold and mildew, and even structural damage.

To prevent these destructive outcomes, no building design today is complete without a continuous air barrier. However, architects and engineers are faced with the challenge of selecting an air barrier from the many types available, including the choice between vapor permeable and vapor impermeable air barriers.

Climate Map

Climate Map

Understanding vapor drive

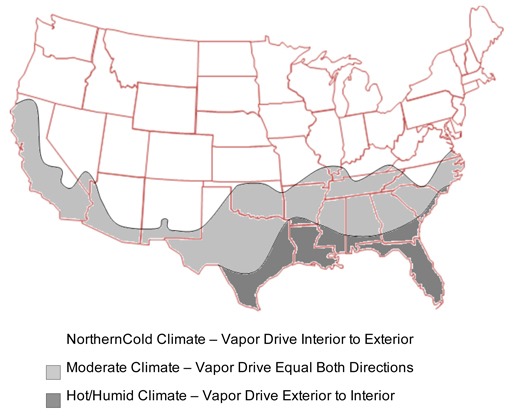

Moisture vapor naturally diffuses into and through wall structures – a phenomenon called “vapor drive.” The degree of vapor drive is controlled by the porosity of the wall, together with environmental factors, especially moisture and temperature gradients. Moisture vapor will naturally move from a high concentration to a lower concentration and from the warm side to the cooler side. The greater the difference of the moisture gradient and temperature gradients, the greater the vapor drive.

What this means is that vapor drive will act differently, relative to a wall, depending on the climate, or even the time of year. (See climate map.)

Diffusion versus condensation

Temperature and moisture gradients also are the key factors driving condensation. As moist, warm air moves across a falling temperature gradient, it cools. When the air reaches its dew point – the temperature at which it can no longer hold water – condensation occurs on the surface bordering the temperature gradients.

In most wall structures, the temperature gradient is greatest across the insulation layer. As warm, moist air on one side contacts the cool or cold, dry air on the other side, vapor condenses – right inside the wall cavity.

On the other hand, under certain circumstances, some degree of vapor diffusion actually may help keep wall cavities dry, by allowing any trapped moisture to escape the same way it got in.

So, while an air barrier is intended to prevent air leakage through a wall, care must be taken to ensure it also helps minimize the chances for condensation in the wall cavity.

Modeling vapor drive

Determining whether to use a vapor permeable or vapor impermeable air barrier – and how to use it – depends on a couple of key factors:

- Climate: Where the wall is located

- Wall Design: Where the air barrier and the insulation layer are located in relation to each other in the wall; what type of cladding is used. When solar radiation heats the highly absorptive cladding, such as brick veneer and manufactured masonry veneer units, following rain, elevated vapor pressures occur and induce inward water vapor flow through the building wall.

To understand how climatic changes interact with specific wall structure designs, a good modeling tool like Grace’s Perm-A-View exterior wall design modeling service can be invaluable. The Perm-A-View analysis is a dynamic simulation of heat and moisture transport through a multi-layer exterior wall exposed to natural weather. The Perm-A-View output is a complete report quantifying the potential for organic (mold) growth on moisture-sensitive wall components and potential for corrosion on corrosive materials. The report also identifies how much energy would be required to maintain the specified interior temperature during a one-year period.

Other important considerations

For any air barrier to be effective in preventing air leakage, it must be continuous as vapor drive can find even the smallest gaps in protection. For this reason, using high-quality flashing systems at all openings is crucial to ensure a continuous air barrier throughout the building envelope.

In addition, the air barrier should be firmly adhered to the wall surface. This is especially critical in wall designs with an air space between the air barrier and the exterior cladding. In these designs, wrap-type air barriers can “billow” to pump air back into buildings or at fastening points, causing it to stretch or potentially tear at anchor points when negative wind loads are strong enough, in effect “inflating” the air barrier envelope. Once breached, the air barrier loses its effectiveness.

The prime choices for a firmly adhered air barrier are self-adhered membranes and fluid-applied membranes. Both are available in vapor permeable or impermeable variations, and both can deliver equivalent performance.

Maintaining optimum dry film thickness of a fluid-applied membrane is critical to its performance. The thickness must be sufficient to cover all high and low points of the substrate. If the layer is too thin, voids can occur, creating leaks.

The value of professional guidance

Both vapor permeable and vapor impermeable air barriers play critical roles in modern wall design. The choice of product is dependent on a wide range of factors, including climate, wall design and other building components. In addition, building materials continually are advancing, presenting architects with new choices, each with its own pros and cons. Working with a professional or manufacturer who has both the technical expertise and the modeling tools to fully evaluate your design against real-world conditions can save you time during the design phase and headaches down the road.

| Product Watch

Fluid Applied Air and Water Weather Barrier System |

DuPont Building Innovations has launched the DuPont Tyvek Fluid Applied Air and Water Weather Barrier System, which offers similar air and water protection of DuPont Tyvek CommercialWrap, but in a fluid-applied form. The system provides coverage and the combination of air and water hold-out and is ideal for application on concrete, concrete masonry unit, gypsum sheathing and complex high-rise buildings.

The complete DuPont Tyvek Fluid Applied Air and Water Weather Barrier system is comprised of Tyvek Fluid Applied Weather Barrier (WB), Tyvek Fluid Applied Flashing and Joint Compound, DuPont Sealant for Tyvek Fluid Applied System and Tyvek Fluid Applied Flashing – Brush Formulation. Applied in one coat by spraying or power rolling, DuPont Tyvek Fluid Applied WB saves time in the installation process. Additionally, combining low shrinkage with high elongation and elastic recovery allows DuPont Tyvek Fluid Applied products to stretch and move with the building, resulting in minimal cracking. Providing the ideal combination of air and water holdout, this fluid-applied product offers vapor permeability of 25 perms.

The DuPont Tyvek Fluid Applied system can play an important role in increasing the overall sustainability of commercial buildings by helping to control air leakage, which allows for more energy-efficient structures by reducing the amount of energy required for heating and cooling. The system also helps to improve indoor air quality by providing protection from water accumulation in the wall system, which can lead to the growth of mold and mildew, as well as wood rot and metal corrosion. Additionally, the system features low-VOC products.

The Tyvek Fluid Applied System can withstand nine months of UV exposure, can be applied to damp concrete and can be applied at temperatures as low as 25 degrees Fahrenheit, providing builders and contractors with more flexibility in their construction schedules. For more information, visit www.weatherization.tyvek.com.

DuPont Building Innovations has launched the DuPont Tyvek Fluid Applied Air and Water Weather Barrier System, which offers similar air and water protection of DuPont Tyvek CommercialWrap, but in a fluid-applied form. The system provides coverage and the combination of air and water hold-out and is ideal for application on concrete, concrete masonry unit, gypsum sheathing and complex high-rise buildings.

The complete DuPont Tyvek Fluid Applied Air and Water Weather Barrier system is comprised of Tyvek Fluid Applied Weather Barrier (WB), Tyvek Fluid Applied Flashing and Joint Compound, DuPont Sealant for Tyvek Fluid Applied System and Tyvek Fluid Applied Flashing – Brush Formulation. Applied in one coat by spraying or power rolling, DuPont Tyvek Fluid Applied WB saves time in the installation process. Additionally, combining low shrinkage with high elongation and elastic recovery allows DuPont Tyvek Fluid Applied products to stretch and move with the building, resulting in minimal cracking. Providing the ideal combination of air and water holdout, this fluid-applied product offers vapor permeability of 25 perms.

The DuPont Tyvek Fluid Applied system can play an important role in increasing the overall sustainability of commercial buildings by helping to control air leakage, which allows for more energy-efficient structures by reducing the amount of energy required for heating and cooling. The system also helps to improve indoor air quality by providing protection from water accumulation in the wall system, which can lead to the growth of mold and mildew, as well as wood rot and metal corrosion. Additionally, the system features low-VOC products.

The Tyvek Fluid Applied System can withstand nine months of UV exposure, can be applied to damp concrete and can be applied at temperatures as low as 25 degrees Fahrenheit, providing builders and contractors with more flexibility in their construction schedules. For more information, visit www.weatherization.tyvek.com. |

Return to Table of Contents