3 Decades of Masonry Estimating

Words: Bill Lula

Words and Photos: Bill Lula, Founder of Masonry Estimating Service

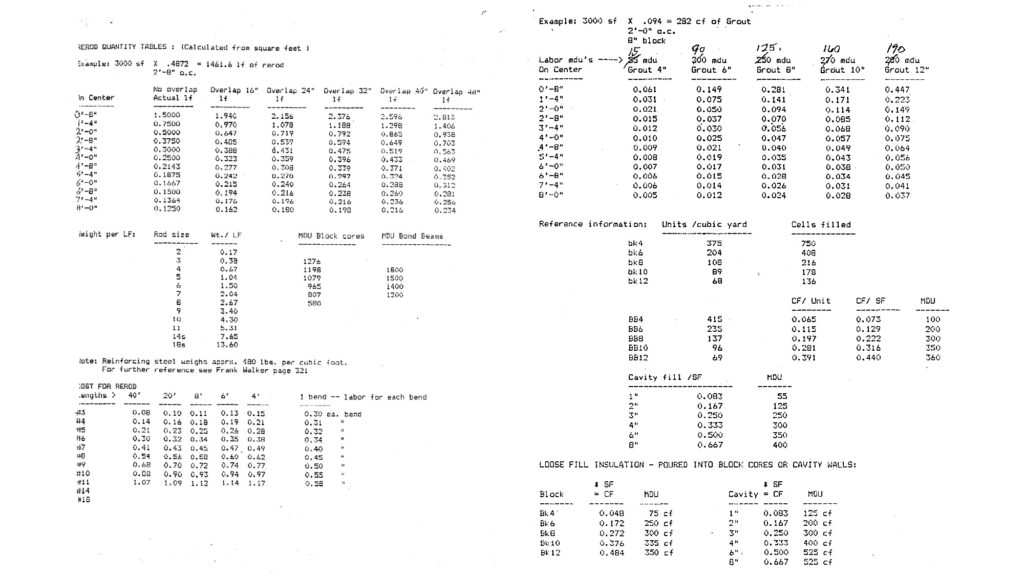

When I started my professional career in 1992, there was no masonry estimating software; there were barely personal computers available. As a young inexperienced estimator, I was self-taught for the most part, figuring things out on my own and using a few charts that were given to me (see below). In the beginning, my takeoff was pretty simple, many sheets of paper with handwritten quantities using a scale and calculator. The most important learning tool for me was asking questions to experienced bricklayers, foremen and project managers. These are the people with the real answers to production rates, crew sizes, equipment and on-site field conditions.

With some knowledge of crews, production rates and some basic masonry-related square foot conversion formulas, I was ready to tackle my first masonry estimating software that was on the market. In the early 1990s, a masonry-specific software was developed by a mason contractor in Michigan called ProE. Back then, our computers didn’t have Windows like the computers of the past 25 years. These computers used MS-DOS and were pretty slow. ProE software was mostly a data entry-based software. I remember tedious hours of data entry on an old keyboard and printing out reports on a dot matrix printer. ProE was fine for its era because it did calculate totals in the end as long as the user inputs the correct quantities.

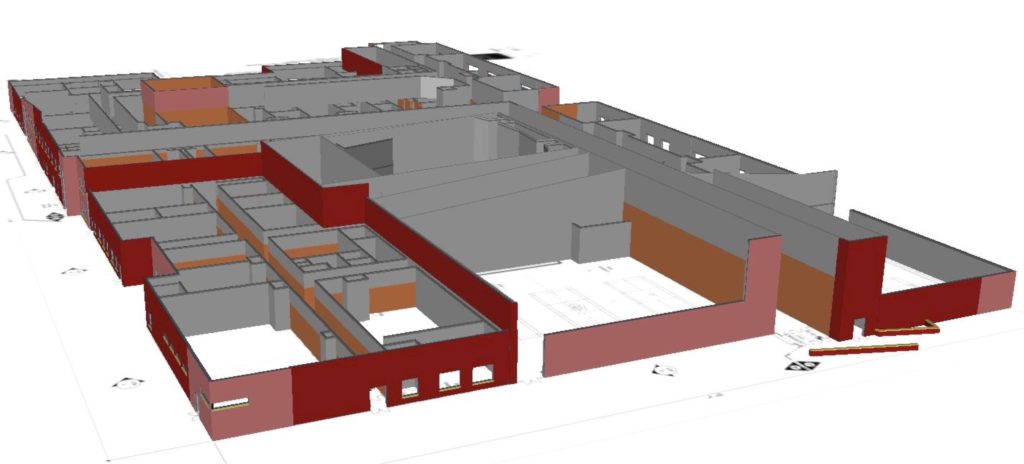

In 1996 I attended the Masonry convention in Phoenix, Arizona, where I met Bill Pacetti Sr. He showed me the masonry estimating software that he was developing. He named it Tradesmens Software, and it was created specifically for masonry estimating. Bill was a mason contractor in Chicago and was frustrated by doing takeoffs long hand and knew there was a better way to estimate masonry as computers were becoming more popular. His idea was to create an assembly with all items in that masonry wall system, including brick, block, flashing, mortar, rebar, grout and even weeps. With this assembly, all we needed to do was enter the length and height of the wall, and the computer would calculate all the quantities. In the beginning, the user still had to use a scale and calculator to estimate the length of the wall. As time went by, a few years later, the next version of the software was released. This new version was a game changer because now we no longer had to use a scale to measure lengths. The software used a digitizer which was pretty large, heavy and pretty pricey at $3,000-$4,000 (back in the late 1990s). All the user had to do was tear out the floorplan from the blueprints and tape the four corners to the digitizer and start clicking on the walls to get lengths. We now eliminated the calculator and scale! Many human errors occur from using a calculator and scale. This next version of the software changed the way we estimated because it was now able to render a 3D view of the walls we were building. Yes, as we clicked on the walls of the floorplan, the wall would appear in 3D on our monitor.

I started my business in 2007 (Masonry Estimating Service) because I saw the ability to provide masonry estimates along with 3D renderings that I could provide to my customers. They didn’t have to call and ask me, “did you get this wall or that wall” or “how about the trash enclosure or foundation block”! What you see on the 3D renderings is what we have included. After one year of having to work in my basement because this was the only place in the house that would accommodate a built-in desk that supported the massive 48”x60” digitizer, the next version of Tradesmens Software was released. This next version eliminated the digitizer and was now “on-screen” estimating. The floorplan was no longer a paper blueprint but a PDF file that was converted to a TIF file and imported into the software. The digitizer was replaced by a large flat screen tv which was only $500 and took up very little space. This new version allowed me to be mobile and have the ability to work from anywhere my laptop went. In 2009 I did my first “on-screen” 3D takeoff on my laptop 10,000 feet in the air heading to the World of Concrete in Las Vegas.

There have been many technological advances in masonry estimating over the past three decades. So, where do we go from here? I believe that someday in the near future, a project will come out for bid, and the architectural drawings will have the quantity takeoff for all materials on the drawings. The estimator will only have to price the labor and equipment costs. Only time will tell!