Resiliency Case Studies

Words: Steven Judd

Words and Photos: Steven Judd, Technical Director of Interstate Brick

“Resiliency,” as a term, has recently come into vogue and consequently has different meanings to different people. Historically, “resiliency” has been described in two different ways:

- The ability of a person or persons to recover from adversity or stressors, which was discussed in a previous article.

- The property of a pliable material to return to its former shape or profile after being impacted by some load or force.

The National Council of Structural Engineers Associations (NCSEA) has chosen to define resiliency as a human trait (definition #1) – the ability to recover from adversity or a stressor - that can be significantly enhanced or augmented by building structures that are robust and durable, meaning buildings that can withstand extreme winds, earthquakes, tidal surges, tsunamis, projectiles, blasts, ballistic impacts and other natural or human-caused events.

Mother nature is unpredictable, and life isn’t fair. If you have never heard that before, now you have. No matter what criteria one uses for the design loads on buildings, or other structures, representing environmental events, such as wind, fire, tsunami, rain, snow, earthquake, etc., or human-caused events; arson, bombs, active shooters, etc., there will be some degree of probability that any given environmental or human-caused “stressing” event will exceed the assumed design criteria. That is real life. It happens. For instance, if a jurisdiction having authority (JHA) or an owner requires the design of a facility for a 100-year storm, you may get a 200-year storm, a 500-year storm, or something larger during any particular storm season, and possibly several times during the life of the structure.

These sorts of extreme environmental and other caused events disrupt typical day-to-day life, especially if a structure experiences a collapse or is damaged beyond repair or occupancy. These sorts of events cause stress on individuals and families. You can’t go to the store and buy essentials if the store doesn’t exist any longer. One can’t cross the river if the bridge was washed away. Recovery has to factor in repair or replacement of buildings that are deemed unusable.

Recovery periods can be shortened when goods and services are quickly accessible after an extreme event, in part, largely due to buildings that do not collapse or are not damaged to the point of creating a public safety hazard, standing but unoccupiable. Masonry buildings have proven to be robust and durable when properly designed, properly constructed, and properly maintained.

Masonry, in general, and reinforced masonry, specifically, has a proven track record of durability and longevity. Masonry mass walls (which are quite energy efficient) are still standing today that were built 1,000, 2,000 and over 3,000 years ago. Part of the City of Jericho was built with bricks around 7,000 years ago. Kiln fired bricks were popularized by the Romans throughout the Roman empire due to portable kilns used over two thousand years ago.

Reinforced Hollow Clay Masonry (RHCM) came into the design vernacular in the 1950s and 1960s, with significant use in the 1970s and later. RHCM combines the extremely high compressive strength of fired clay material with the high tensile capacity of reinforcing steel, producing wall systems that can be assembled in place that can easily exceed the capacity of typical reinforced concrete or reinforced CMU construction.

Some examples of enhanced resiliency offered by robust and durable Reinforced Hollow Clay Masonry (RHCM) follow:

Case Study 1

The Maritime Museum in Galveston wanted to create a structure that would be able to protect the museum exhibits (expensive to replace) and chose to use Reinforced Hollow Clay Masonry (RHCM) because of its inherent strength, knowing that Galveston is in the hurricane impact area along the coast of the Gulf of Mexico, and for the beauty of brick. As one might expect, Galveston was hit by a hurricane. Hurricane Ike shortly after the museum was completed in 2008. The area surrounding the museum was flooded for several days, but the contents of the museum were safe. When the water level retreated, the exterior walls were washed down with soap and water, and the museum was ready for the public. There was no damage to the building, and no expensive repairs to the structure were required. The water did not damage the RHCM walls. The recovery period to put the building back “online” was only the time required to wash the outside of the building. Patrons were able to visit the museum almost immediately after it was cleaned. Nine years later, Galveston was hit by another hurricane - Hurricane Harvey. Same result to the Maritime Museum: no structural damage while the exhibits and artifacts remained safe.

This maritime museum facility serves as a prime example of the strength and durability of RHCM, which significantly reduced the recovery period after the hurricanes due to the lack of damage and the preservation of the exhibits in the building. The employees and patrons were able to return to the facility very quickly.

Case Study 2

Since 1957 there have been 20 tornados within a 10-mile radius of Birmingham, Alabama. Fultondale, AL, a city several miles to the North-East of Birmingham, was hit by an EF2 tornado in 1957. In 1958 and 1990, two more EF1 or higher tornados approached within 3 miles of town. In a more recent event, on April 27, 2011, a tornado went through Fultondale with devastating consequences, which was the reason the community applied for and received a FEMA grant to help build a tornado shelter and community center. The interesting thing about FEMA grants is that they help cover the majority of the cost of the primary structure but none of the costs of the non-structural elements. In some communities, to enhance the look of the storm shelters and help them blend better into the community, concrete and CMU structures are frequently faced with brick veneer, so the storm shelters look less industrial and more like the typical residential architecture. In Fultondale, AL, Interstate Brick produced a special one-slot HRCM brick that provided the appearance of two modular size brick, 2.25” tall and 16” long, with a vertical slot in the center. These units were laid in one-quarter/three-quarter bond to achieve the standard residential look of a half-running bond modular brick veneer. The units were 8” thick/deep and capable of resisting the FEMA prescribed projectile resistance – three shots of a 15-lb, 10-foot long, wood 2x4, shot at 100 mph.

Since the brick units were the primary force revisiting system for vertical and lateral loads, the FEMA funding covered most of the cost of the RHCM brick, reducing the cost to the community. No additional brick veneer was required to achieve the residential brick appearance. The community donated the property adjacent to the First Baptist Church, which local funding participation is required for FEMA storm shelter grants. Having a single wythe wall reduced the cost of the facility (as compared to brick over block) to the government, and to the city of Fultondale, with the bonus of providing the beauty of residential masonry.

This tornado shelter is intended to protect and preserve life, reduce injury, and help the community of Fultondale to bounce back more easily from a devastating extreme wind event.

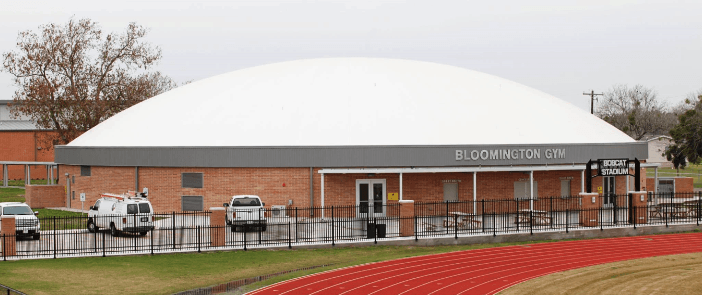

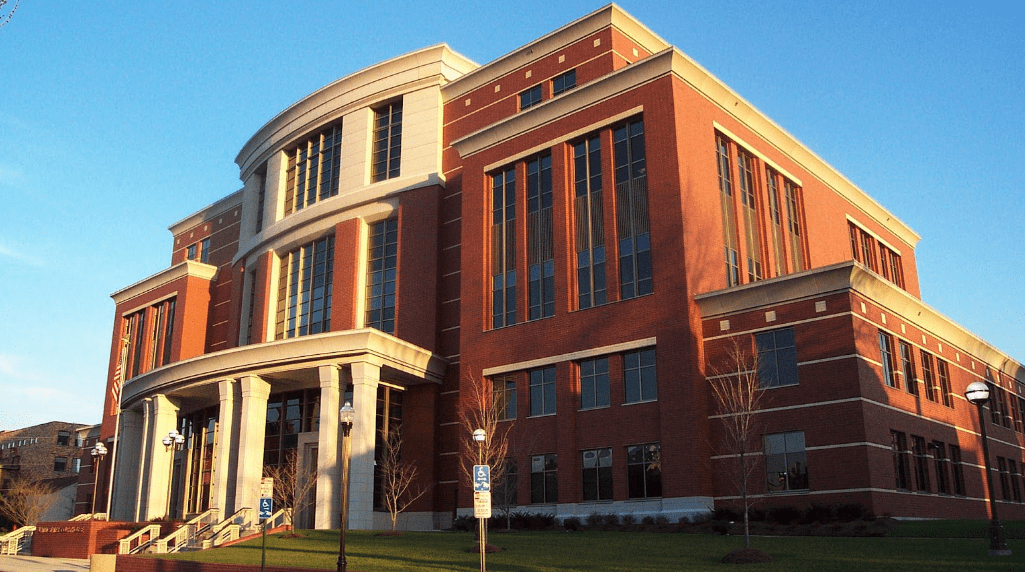

There are many more examples where RHCM has been used to provide robust and durable facilities that enhance resiliency of individuals and communities and where extra protection from extreme events was required, as in the following facilities: Carlos Garza Park Pavilion, City of Texas City, TX; US Customs Building, Conroe-North Huston Regional Airport, Conroe, TX; Community Storm Shelter and Bloomington High School Gymnasium, Bloomington, TX; US Federal Court Building, Covington, KY; Fire Station No. 8, St. Petersburg, FL.

Carlos Garza Park Pavilion, Texas City, TX

Carlos Garza Park Pavilion, Texas City, TX

Bloomington, TX

Bloomington, TX

Federal Courthouse, Covington, KY

Federal Courthouse, Covington, KY

Fire Station No. 8; St. Petersburg, FL

Fire Station No. 8; St. Petersburg, FL

If one wants to build a facility that is intended to be long-lasting and durable, to resist extreme events, to enhance the resiliency of individuals and communities, why not use a proven building system such as RHCM, which can provide extremely robust and durable facilities, in addition to having the lasting beauty of brick?