Enhancing Jobsite Safety Through 'COPS' - Continuous Oversight and Proactive Systems

Words: Tom Vacala

Not the police officer COP

Words: Tom Vacala, https://brcconsulting.org/

Photos: Tom Vacala, MASONRY Magazine

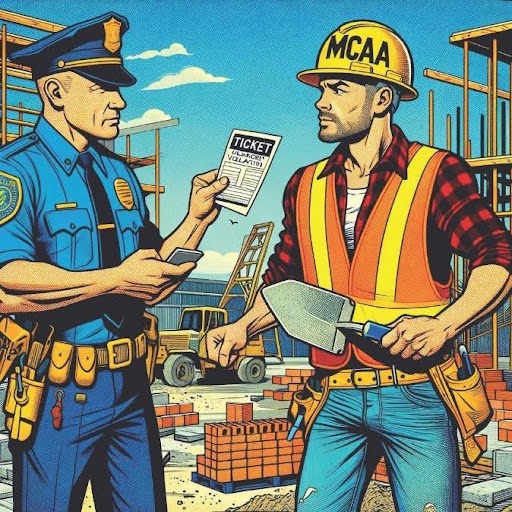

Have you ever felt like the bricklayer in the picture above, getting a ticket for a violation on a jobsite? Or have you ever found yourself playing the role of a police officer, giving out safety violations? Many of us in the masonry construction industry can relate to both scenarios. However, introducing and maintaining a culture of safety in a workforce accustomed to traditional practices can be a challenging transition. But it's a necessary transition.

Transition is the key word here, defined as the process or period of changing from one state or condition to another. Winston Churchill once said, "To improve is to change." While we understand that safety enhances the longevity of our bodies in the construction industry, we Masons have a reputation for being a tough crowd, reluctant to change the way things have always been done. We used to say, "It's construction; you're supposed to get cuts and bruises. Brush it off and get back to work!" Well, that sales pitch doesn't work anymore. If you believe in workforce development, you should also believe in taking a different approach to how we are perceived by the next generation. This starts with transitioning to a safer working environment, not an overnight change. Change may not be our industry's favorite word because it's unpredictable and sometimes perceived as uncontrollable.

However, as great leaders like John C. Maxwell have stated, "Change is inevitable. Growth is optional." So, here's the truth: Implementing and monitoring safety is inevitable. Safety has always been here. The question is, are we implementing and monitoring safety systems for the growth of our companies and our employees, or are we forcing employees to change like a police officer handing out tickets? These seem to be our options.

Let's discuss four systems that industry leaders have used to transition their companies into a "safety culture" that not only attracts new employees but also develops existing ones:

1. Safety Checklist

Using a safety checklist directly related to your company's common work tasks simplifies inspections across all sites. This checklist accomplishes several things:

- Eliminates the perception of being singled out for inspection, as it's used consistently across projects.

- Allows for pre-inspections by site superintendents/foremen, ensuring readiness before safety personnel arrive.

- Provides a fair assessment with checkboxes (safe or unsafe) and explanations for each item. Unsafe items require descriptions of the issue and how to make it safe.

- Satisfies OSHA requirements for safety records, demonstrating inspections and prompt correction of citations.

2. Safety Committee

As Phil Jackson, the legendary coach, said, "The strength of the team is each individual member. The strength of each member is the team." Building a checklist or safety policy alone is insufficient; you need a team. Create a safety committee comprising various employees, from the safety director to laborers, bricklayers, tuckpointers, project engineers, and drivers. The policies should be employee-generated and accepted by every trade within the company. This committee can meet regularly to create new policies and toolbox talks based on recent citations, near misses, OSHA updates, or accidents. When forming your Safety Team, diversify your membership.

3. Understanding the Jobsite

Don't just do a drive-by inspection; spend time on-site in the trenches. Each jobsite has unique circumstances that need to be understood before advising workers on safe practices. Consider organizing a "hand-off" meeting before mobilizing a jobsite, involving the safety director in the process. This meeting is an opportunity to create a site-specific safety plan based on employee insights. It's another step toward ensuring safety policies are designed for employees, by employees.

4. Show and Tell

When inspecting safety, your role is to show the correct or safe way to perform tasks. Just like children, adults learn through show and tell. Visual aids are essential for our construction-oriented minds. Capture pictures of corrected items to educate others. Include pictures in reports and training materials to help employees retain correct habits (see examples of violation pictures below).

In this article, I haven't wasted your time telling you what needs to be inspected; that's knowledge you already possess. What sets us apart from the "Police mentality" is how we inspect jobsites. Enhance your company’s jobsite safety through 'COPS' - Continuous Oversight and Proactive Systems. Implementing this approach will help your company develop a Safety Culture that attracts new employees and nurtures the development of existing ones.

Access Job Site Audit Form Here