Image 2: Seattle Lemiux Library Seattle Pacific University Seattle, WA

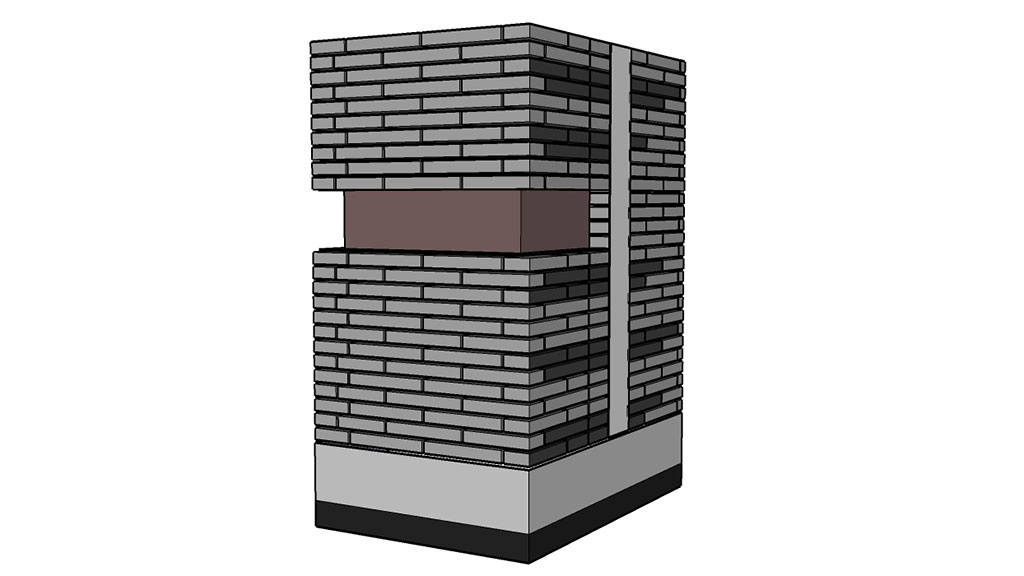

Image 3: Subway Transit Station Capitol Hill Seattle, WA

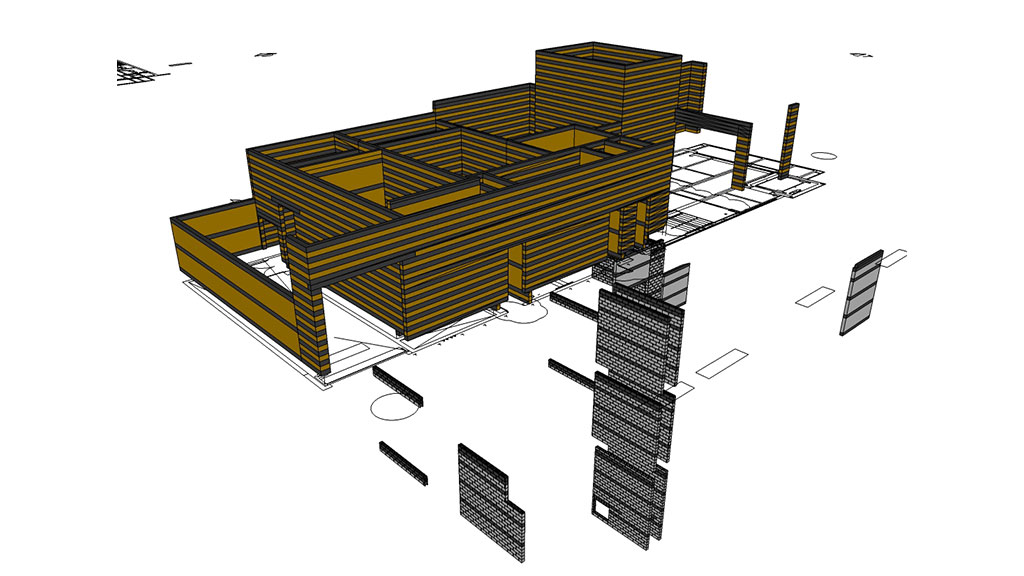

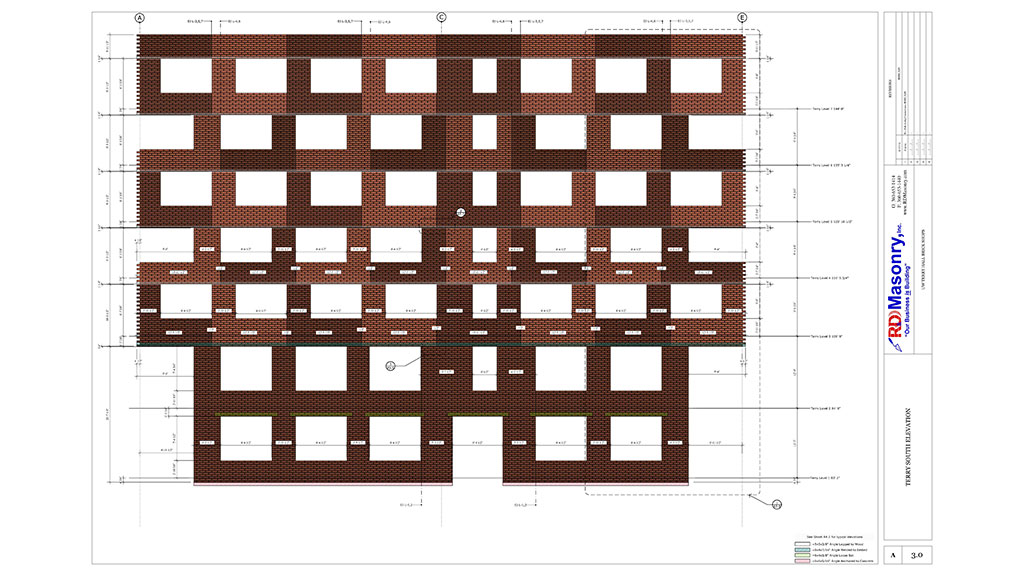

Image 4: University of Washington Maple and Terry Hall Seattle, WA

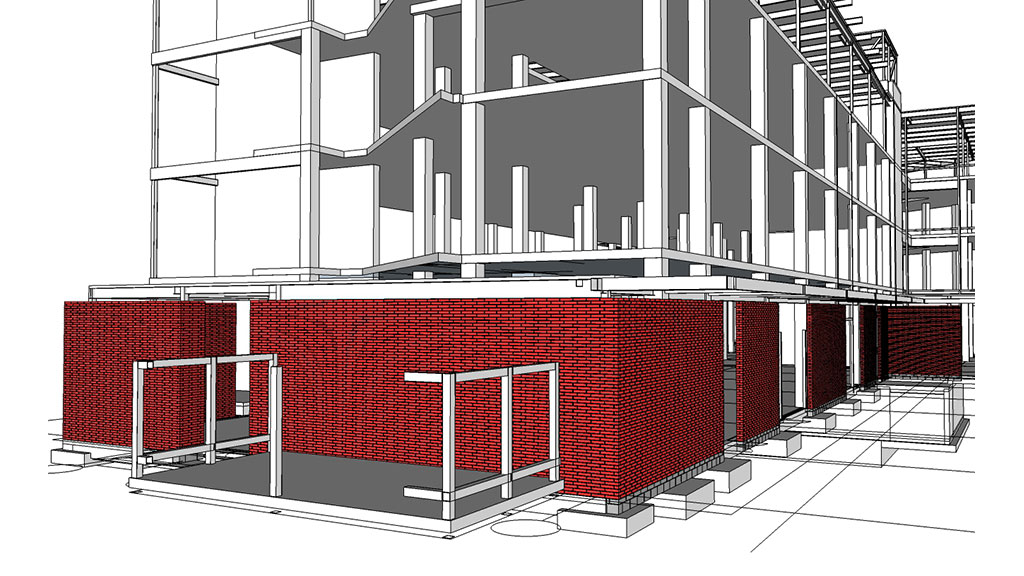

Image 5: Washington State University NPSE Everett, WA