Extracker Software: Streamlining Worksite Documentation

Words: Christopher Rodermond

Words: Christopher Rodermond

Photos: Extracker Software

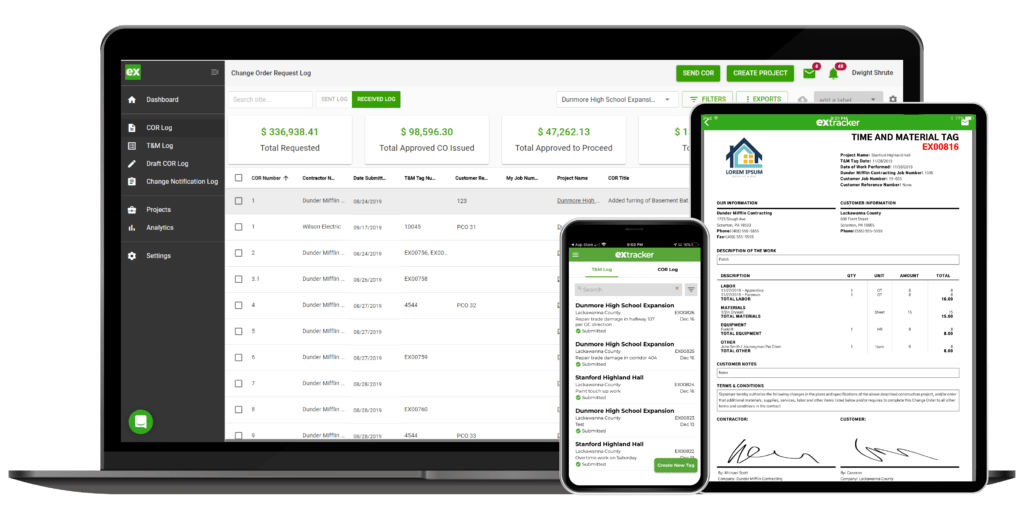

There are many choices for software designed for the construction industry. One that was designed for the field and the office is a mobile and web app called Extracker. This software is a point solution that works in between ERP systems to help create, track, and share costs sent between contractors. All users report their data through a smartphone mobile app for stakeholders to see realtime cost exposure on a uniform platform.

This software promises to address a number of process improvements through paperwork reduction and real-time access to potential cost and budget fluctuations. The free to use service can bring transparency through time-stamped photos submitted of work or changes completed. This allows for smoother interactions between contractors and their subcontractors, as well as with the management and project owners.

The old way of doing things, and what this software aims to address, was explained to us in more detail by Cameron Page, CEO of Extracker Software. He brought his insight into what he is trying to accomplish with this product, and as a general contractor himself, he has tried to build a platform that he understands will be helpful for the industry.

From the job site to the office:

Does any of this sound familiar or resonate with you? Are you using carbon copies to track the number of materials, equipment, and labor your team spent on each project? Does the site superintendent for the general contractors sign the document verifying your hours or scope of work? Finally, does the time and material tag have to be driven back to the office?

Then, the process starts. The office supplies all the labor rates to the job, the number of materials, and the equipment used in a change order request. The request is entered into a PDF, the time and material tag will get scanned, and then both are emailed to the general contractor. Once sent it is reviewed and approved for the final cost, but executing an approval can be time-intensive and a huge administrative burden. That process happens hundreds of times on a small commercial project to thousands of times on a large commercial project.

Extracker software attempts to eliminate those steps. A person on the job site can track the amount of labor, material, and equipment being spent and immediately make a record with a photo and description. No longer handwritten, it is more legible, and the software also supports voice to text.

From the office back to the job site:

Not only does the industry start this process with paper, but it also continues it with a combination of spreadsheets, emails, pdfs, and other documents. After everything is generated and updated in several places, a final round of emails are exchanged between the different parties. Once the signatures are obtained, and the general contractor has successfully made changes to the original contract, the project can be completed.

Page noted that the only way to know that a change order form was not missed, was to email each subcontractor. He would have them confirm by sending their change order log, complete with all documents previously sent for that project. Then the subcontractor would have to update the Excel log, and send a PDF in and email it to the general contractor. That back and forth process was constant.

After all, Page thinks one of the biggest risks in construction is missing important costs causing your forecast of a project to fall out of sync with reality. To him, this is the fundamental reason why we hear about big projects going over budget. It is not because of a labor shortage, a design flaw, or even some unforeseen reason. The real reason one will wind up over budget is that all the costs were not updated, communicated, and approved in time. All the costs go into a bottleneck and if a person knows about the cost in real-time, one can proactively make a change. If it is noticed that certain costs are adding up fast, a manager can stop and address it, change direction, and mitigate the overage in the project. The problem is with the existing process that cannot be done easily when everything is mixed between paper, spreadsheets, and emails.

On his last project Page had about 2,500 subcontractor change order requests and he tracked all of those through email. They downloaded each file into a folder and typed it all into an Excel spreadsheet, and then uploaded those numbers into their accounting software.

A different way:

When the subcontractor sends the change order request through Extracker, a user can send information directly from the web-based software and it will automatically log the change order request.

A user can invite their general contractor to use the software, (it is free for the G.C. to login and view those costs as they are accumulating). Extracker also has a cloud storage function by which you can send a shareable link to your change order log for each project. You are also able to email that link to the general contractor, which will give them access to all the change order requests for each project to keep them organized and up-to-date.

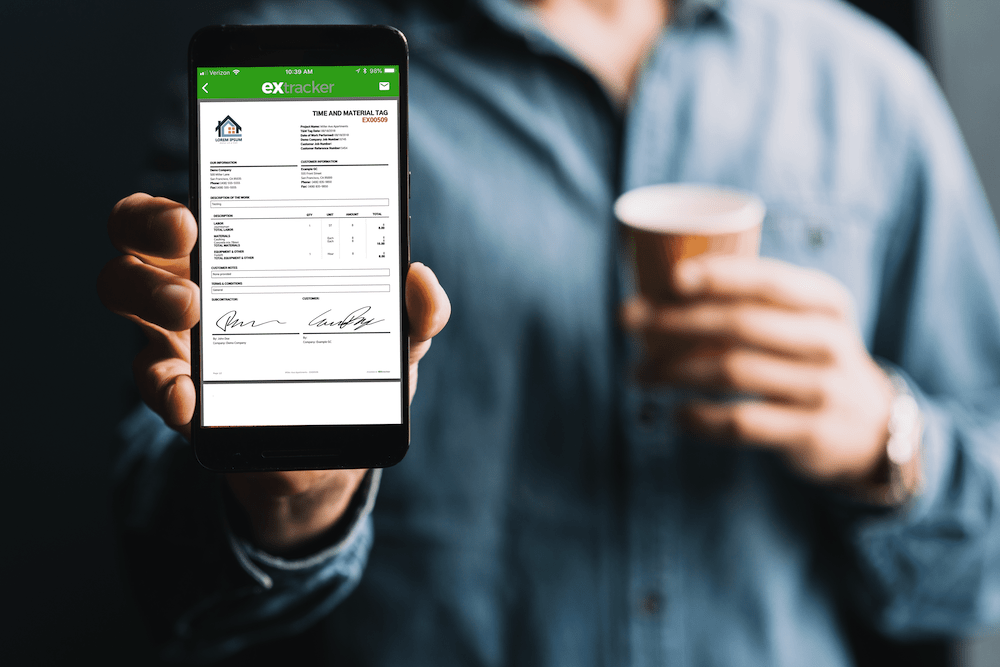

Perhaps the most powerful but simple benefit is uploading the time-stamped photos of work as it is completed. Subcontractors can take before and after photos of their work and write a description, to ensure they are reimbursed. Once the document is ready, the site supervisor can sign off on it right on their device, using a signature email request similar to DocuSign.

This has also proven to be a valuable feature with social distancing requirements on the job site and less interest in sharing paper documents.

“A simple scenario can be imagined that as a general contractor superintendent you might have 20 or 30 subcontractors on your project. If they all have to work overtime on a Saturday to get the job back up because everyone has been sitting on the sidelines, each one of those subcontractors is going to be handing that superintendent a paper and material tag.”

The time this software can save, after data is logged into the mobile app, can be considered when the information is immediately sent back to the home office. It is then possible to automatically price out the change order request, share it with the customer, and track every document. In this economy, the most important part of this solution is helping contractors track their revenue when margins are tighter. By knowing what change orders can be billed the contractor is able to make informed financial decisions for their business.

Extracker is focused on improving three things: quality of the documentation, speed, and organization. The crux of the software is the way it keeps track and logs the changes on each project for each subcontractor. The general contractor will write a contract for each subcontractor on a project. For instance, if there is an electrical contractor, drywall contractor, concrete contractor, and mason contractor, each one of them will receive an individual contract for the project. Inevitably things change in construction, this is why the original plans are important. Whether it is the owner changing their mind, overtime popping up, or unforeseen conditions, you always need the original plans. For instance, like finding out about an unknown gas line and needing to change from a CMU wall, whatever it might be, changes are part of construction. Extracker will produce the change order forms from each individual subcontractor, allow the GC to approve and notify the subcontractor of the changes, and organize all change order forms by the subcontractor for each project. The change order process is there to track those changes and it is a legal process to adjust someone’s contract.

More information:

Extracker offers a basic version for free on the company website, or download the mobile app and you can begin creating time and material tags. You can also sign up for premium features of the software to start inviting subcontractors to a project, who will be prompted to create their own accounts. Permission levels are simple. There is an admin user on every account with access to all projects, all labor rates, all material rates, and the account setup. Each project manager will have access to their assigned projects, and field users will be able to access the time and material tag for their projects. So, whether your company is looking for a new app or software to help simplify things while working on a job or jobsite, consider exploring the Extracker site along with other apps to see if it will be a solution you may need.