Product Spotlight: Porphyry for Stone Paving

Words: Dan Kamys

By Miles Chaffee

Now is the time to take a cue from history’s greatest architectural minds – the Romans – by embracing porphyry, a volcanic rock, in an increasing variety of paving and building projects throughout North America.

Now is the time to take a cue from history’s greatest architectural minds – the Romans – by embracing porphyry, a volcanic rock, in an increasing variety of paving and building projects throughout North America.

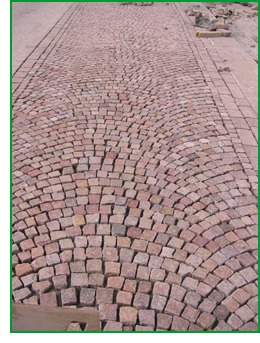

Builders, architects, developers and consumers are catching on to porphyry and its numerous advantages in paving and other projects. Porphyry and its enduring – and endearing – qualities of Old World beauty, hardness, impermeability, chemical resistance, freeze/thaw resistance, green attributes and long-term affordability are making this material a major player in the multi-billion dollar stone-paving industry.

New methods are constantly being developed to meet updated environmental standards in both commercial and civic markets. However, a successful and environmentally friendly paving application has been around for more than 2,000 years: roads created from a durable stone called porphyry. And, those roads are still here today.

Permeable pavers

Many different types of permeable pavers are available. When set correctly, natural stone pavers, such as porphyry,??offer the best value over time, due to??their??durability. But each type of permeable paving has its pros and cons. In terms of cost, gravel is the least expensive. However, it requires frequent maintenance and renewal, at a cost. It also forms wheel ruts easily.

Permeable concrete and asphalt are next in terms of expense, but studies have shown them to be prone to clogging, negating their effectiveness. A study conducted by the Metropolitan Engineer’s Council in Denver showed a complete failure of permeable concrete under freeze-thaw conditions. The City of Rosemary Beach, Fla., tore out permeable concrete city streets, due to clogging, and replaced them with concrete pavers with permeable joints.

Brick, concrete and stone pavers require that the material in the joints be permeable in order to be considered permeable overall. Brick must be the correct brick and manufactured to specific requirements in order to be used as a paving material, especially in freeze-thaw climates. Constant freezing and thawing is harder on materials than climates that freeze and remain frozen for long periods. Concrete pavers offer a low-cost option for paving and can last 10 to 15 years, just as brick can.

Porphyry is durable. European roads have been in place for hundreds, if not thousands of years. Again, the joint material must be permeable.

Considering cost

Porphyry can be expensive, but long outlasts other materials. Still, the issue concerning many civic leaders when considering permeable paving options is cost. While many cities, industries and businesses are scrambling to become environmentally friendly or market themselves as being green, a few affordable options are available and recommended for permeable paving systems.

When considering upkeep, maintenance and deterioration, porphyry will save thousands of dollars over the long haul, since it lasts a lifetime. Porphyry likely will never need to be replaced, and requires a minimum of maintenance over a long period.

In the end, the use of permeable paving systems can and will, ultimately, save urban areas millions of dollars in maintenance and storm water management costs. However, until cities find the funding for these projects, they will be forced to install the quick, more cost-efficient options and spend thousands, if not millions, in upkeep.

Miles Chaffee is the founder and president of Milestone Imports. For more information, email him at info@milestoneimports.com or call 505-989-1999.

Return to the main story: