Tuckpointing and Repointing Tools

Words: Dan Kamys

Tools

By Brett Martin

Masonry contractors have many options when it comes to tuckpointing and repointing tools. Whether the preference is an electric grinder or a hammer and chisel to remove mortar, or a drill attachment or a tuckpointing trowel for applying mortar, a variety of new and improved tools exists for this niche market.

Some companies, like Bosch Power Tools and Accessories in Mount Prospect, Ill., focus on a single specialized tool, in this case, the tuckpoint grinder. Other companies, like Kraft Tool Co. in Shawnee, Kan., manufacture hand tools and accessories for all types of tuckpointing and repointing work, including removing old mortar, cleaning out the joint, and replacing and finishing the mortar.

Bosch-Five-inch tuckpoint grinder

Grinding mortar and collecting dust

Since grinders are often used to remove mortar, Bosch designed a grinder dedicated for exactly that purpose. The five-inch tuckpoint grinder with 8.5 amp, 11,000 rpm motor offers variable depth adjustment.

Bosch-Five-inch tuckpoint grinder

Grinding mortar and collecting dust

Since grinders are often used to remove mortar, Bosch designed a grinder dedicated for exactly that purpose. The five-inch tuckpoint grinder with 8.5 amp, 11,000 rpm motor offers variable depth adjustment.

"The advantage of using it over a grinder is it adjusts easily to the depth of the work," says Ryan Anderson, product manager for the metal category for Bosch. "This particular tool has a spring-loaded guard that can be adjusted to the desired depth. You can get a consistent depth across the wall."

A dust extraction port can be attached to a vacuum to control dust during grinding, Anderson says. "It's dust free, for the most part."

Tuckpointing tools typically run for hours without stopping, so the tuckpoint grinder has an overload protection that reduces power by about 50 percent if the tool starts to overheat, he says. The tool runs at half power, which lets the operator continue to work without damaging the motor.

"If the tool is overheating, it reduces the amount you take off per pass," Anderson explains, adding that proper care will extend the tool's life. "Storage is a concern. Don't leave it on the ground or in a pile of dust. Keep the tool dry and clean."

During use, Anderson recommends letting the blade patiently cut the mortar without pushing the tool to cut faster.

"Relax and let the wheel remove the mortar," he says. "Let the tool do the work. Don't force it. Slow down a little instead of ramming it through. You don't need to be aggressive."

Tuckpointing blades

and chisels

For removing mortar with grinders, Grandview, Mo-based Diamond Vantage Inc. offers diamond-tipped tuckpointing blades that remove one-quarter inch of mortar per pass.

"The tuckpointing blade is thicker so it removes more mortar," says Jeff Shermo, regional sales manager, East Coast, for Diamond Vantage. "It's faster to cut out the joint in one pass than to go back and knock it out."

Available in four- to seven-inch diameters, the blades have 45-degree bevels on the outer edge.

"The bevel is for a little faster penetration," Shermo says. "The blades save a lot of time and money, and they give a cleaner, cosmetic look to the joint."

Although grinders are available for removing mortar, hammers and chisels are still used, says Steve Cook, sales and marketing manager for Kraft Tool. Sometimes, the masonry contractor may not have electricity available for a grinder, doesn't want to hassle with running extension cords for a small project, or needs to ensure that the brick isn't disturbed or damaged during the job.

"The mason has to adapt to what works best for him for removing the mortar," Cook says.

Kraft Tool - Plugging Chisel

Kraft Tool - Plugging Chisel

Kraft Tool offers a special tuckpointing chisel, called a plugging chisel, that's 10 inches long, balanced for a comfortable hold, and has a 45-degree angle on the end.

|

?? |

Kraft Tool - Wire Brush with Metal Scraper

|

|

?? |

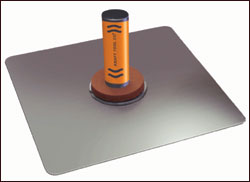

| Kraft Tool - Hawk Trowel

|

"It's made to push the mortar out of the joint as you're working," Cook says. "The 45-degree angle on the chisel is ideal to work in all types of joints."

The company also has chisels with fluted sides. Mortar is pushed out through the sides of the chisel as the worker hammers the chisel into the mortar joint, Cook says. Kraft Tool also offers stiff-bristled wire brushes and masonry brushes for cleaning the joint after removing the mortar.

"You're always going to leave some debris in the joint," Cook says. "The brushes get the dust particles and anything else you left behind out of the joint so the new mortar will stay."

Quikpoint - Mortar Gun

Replacing and finishing mortar

Concord, Mass.-based Quikpoint Inc. offers a tool for quickly putting mortar in the joints. The Quikpoint Mortar Gun attaches to a drill, which turns an auger that moves mortar from a hopper through a steel nozzle into the masonry joints.

Quikpoint - Mortar Gun

Replacing and finishing mortar

Concord, Mass.-based Quikpoint Inc. offers a tool for quickly putting mortar in the joints. The Quikpoint Mortar Gun attaches to a drill, which turns an auger that moves mortar from a hopper through a steel nozzle into the masonry joints.

"This fills the joint completely in one application with no air pockets. This thing flies like mad," says Al Aronie, company president and Quikpoint inventor. "It's much faster, especially for someone who's not real experienced. We've had people say, 'We started a business because of this.'"

Kraft Tools - Caulking Trowel

Kraft Tools - Caulking Trowel

After inventing the Quikpoint about 20 years ago, Aronie refined it over the years with several design changes. He made the last major change three years ago, increasing the hopper size to hold three, rather than two, quarts of mortar.

"It's a real delicate balance between what people can hold and how much they want to hold," Aronie says.

Aronie recommends using lime in the mortar or Gibco's MRF additive, a lime substitute that retains water, to allow the mortar to be squeezed through the nozzle. The tool cleans up by running water through it.

"It's a super easy item to clean up," Aronie says. "It has to be simple to be used with mortar."

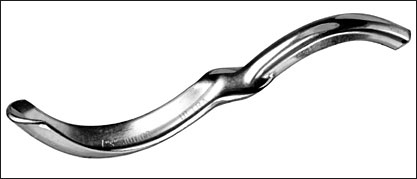

Kraft Tools - Jointer

Kraft Tools - Jointer

Kraft Tool has a full line of hawks and tuckpointing trowels, or caulking trowels, for putting fresh mortar in the joints.

"The caulking trowels are one piece forged carbon steel and come in various widths from 3/16 inch to one inch," Cook says. "The trowels are flexible to allow you to work mortar into the joint."

For finishing the mortar joints, the company offers slickers and jointers.

"There are several ways to finish a joint, depending on the building's architectural style," Cook says. "We have slickers for flat, concave, convex and grapevine joints."