The Hierarchy of Fall Protection

Words: Isa Stein

Sponsored By: Malta Dynamics

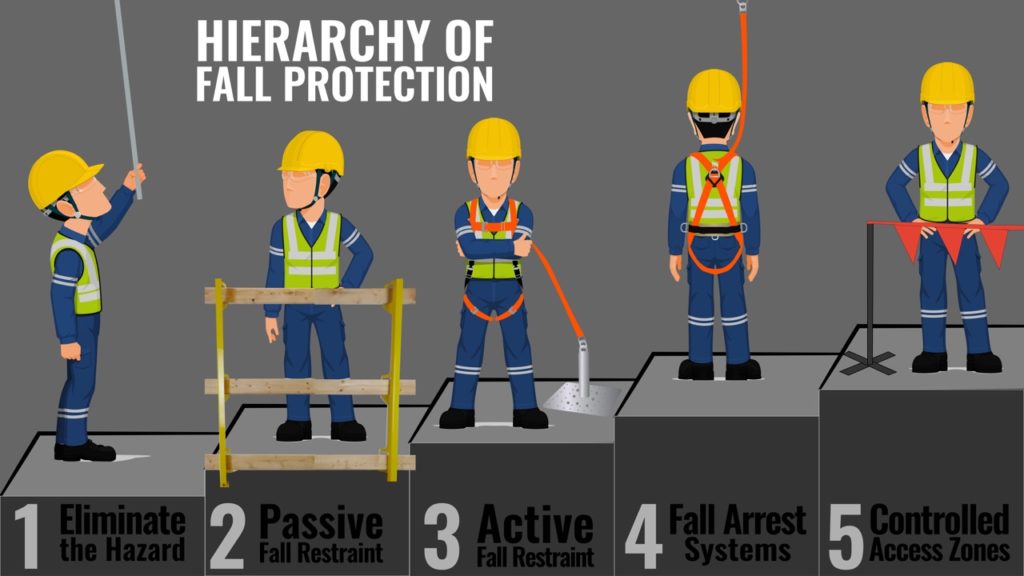

Fall protection is a critical aspect of workplace safety. With falls being the leading cause of fatalities in the construction industry, it is essential to implement fall protection measures to prevent injuries and fatalities. In this article, we will discuss the 5 preferred methods of fall protection. This is a guide to ensuring your workers are as safe as possible for the required t ask. The succession begins with removing fall hazards, then passive fall restraint, active fall restraint, fall arrest, and finally, controlled access zones. This is what Malta Dynamics calls the Hierarchy of Fall Protection:

1. REMOVING FALL HAZARDS

The best way to protect workers from falls is to remove the fall hazard altogether. This can be achieved by performing work on ground level and then using material handling equipment to place material at heights, engineering controls to be used at ground level, or using materials at height that require zero maintenance and inspection, if possible.

2. PASSIVE FALL RESTRAINT

Passive fall restraint systems prevent falls from occurring by creating a physical barrier that prevents workers from reaching the fall hazard. This can be achieved through the installation of guardrails, barricades, or fencing. Passive fall restraint systems are ideal for areas where workers need to move around freely without being encumbered by additional equipment. This means there is no risk of a fall, so the worker does not wear a safety harness, nor are they required to receive and maintain specific fall arrest training for that hazard area.

Passive fall restraint is especially preferred in factories or facilities that are permanent or semi-permanent and on work that is performed regularly.

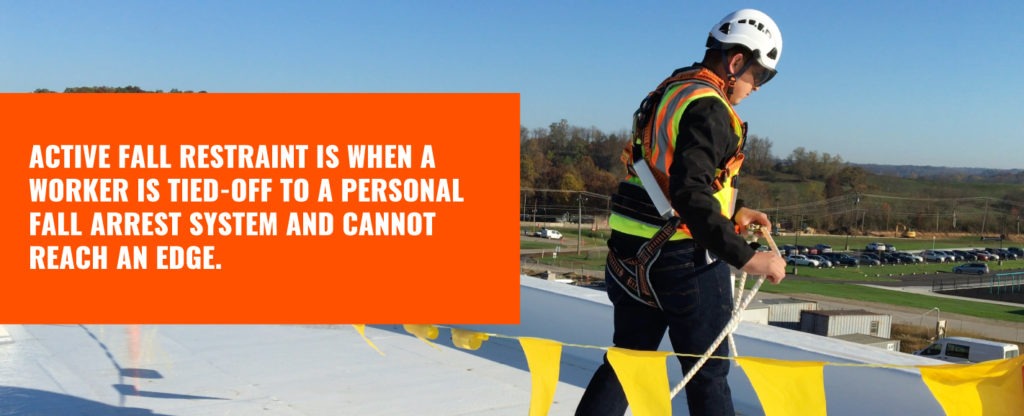

3. ACTIVE FALL RESTRAINT

Active fall restraint systems limit the worker’s movement, preventing them from reaching the fall hazard. This is achieved using a full body harness, lanyard or self-retracting lifeline, and other equipment. The worker is connected to an anchor point, which restricts their movement to a safe zone. Active fall restraint systems are ideal for areas where the fall hazard cannot be removed or protected with passive fall restraint systems.

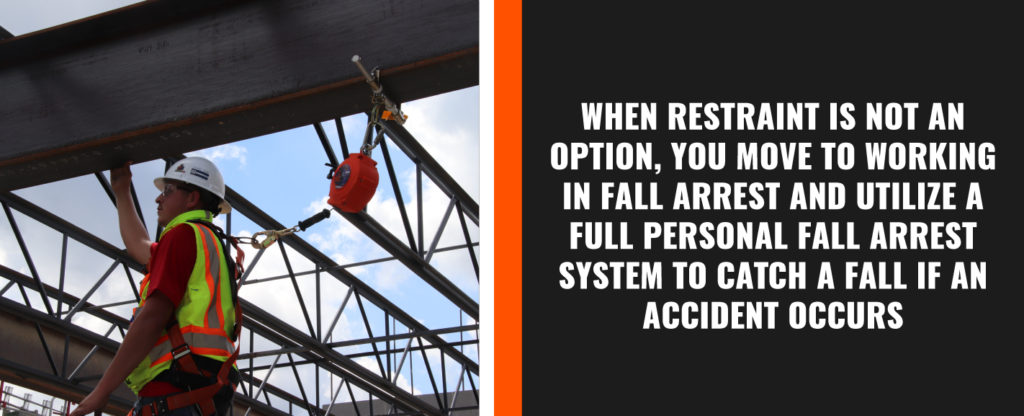

4. FALL ARREST

Fall arrest systems are designed to protect workers who must perform work where fall hazards exist, with a goal to utilize equipment to minimize swing-fall, freefall distance, and arresting forces to the body of the worker. A personal fall arrest system (PFAS), which includes anchorage, bodywear (full body harness), connector (properly rated carabiners and attachment points), and a deceleration device (lanyard or self-retracting lifeline (SRL)). When a worker falls, the PFAS activates, arresting their fall and preventing them from hitting a lower level or other objects that can cause injury. Fall arrest systems are ideal for areas where the fall hazard cannot be removed or protected with passive or active fall restraint systems.

5. CONTROLLED ACCESS ZONES/SAFETY MONITORING SYSTEMS

Controlled access zones are areas where visual barriers represent a no-go area, preventing workers from accessing the fall hazard. These zones are often used in conjunction with other fall protection systems, such as passive fall restraint and active fall restraint. Controlled access zones are ideal for areas where the fall hazard cannot be removed or protected with other fall protection systems.

Safety monitoring systems are an option on low-slope roofs that incorporate a Competent Person who monitors the hazard area and acts as an attendant for the zone. It’s important to note that the controlled access zone and safety monitor options are a last resort. OSHA is specific to mention that they are options only if the safer options are proven unfeasible; however, OSHA assumes that the other options would be feasible, so if you’re incorporating one of these last 2, it’s a good idea to document that you’ve exhausted the safer options.

In conclusion, fall protection is essential for workplace safety, and employers must take proactive measures to protect workers from falls. By removing fall hazards, implementing passive and active fall restraint systems, using fall arrest systems, and creating controlled access zones, employers can prevent injuries and fatalities.